Method for levelling metal plate with stress deformation by utilizing vacuum annealing

A technology of stress deformation and metal plate, which is applied in the field of annealing and leveling of metal plates with stress deformation, can solve the problems of low leveling accuracy and limited leveling effect, and achieve the advantages of simple equipment, shortened production cycle and reduced production cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] For low-carbon steel plates with a thickness of 20 mm and a winding degree of 8 mm, the method of the present invention is used for leveling by means of vacuum annealing. The annealing condition is to keep warm at 800° C. for three hours.

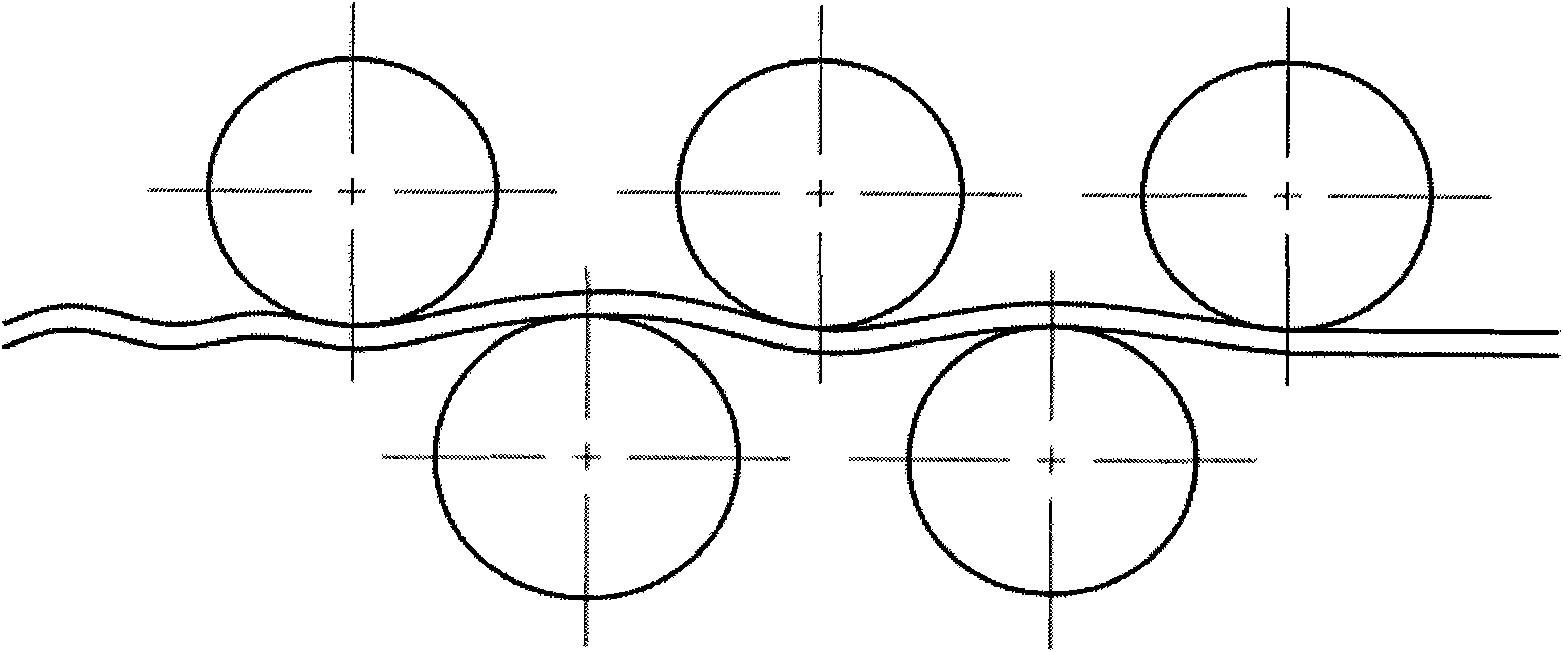

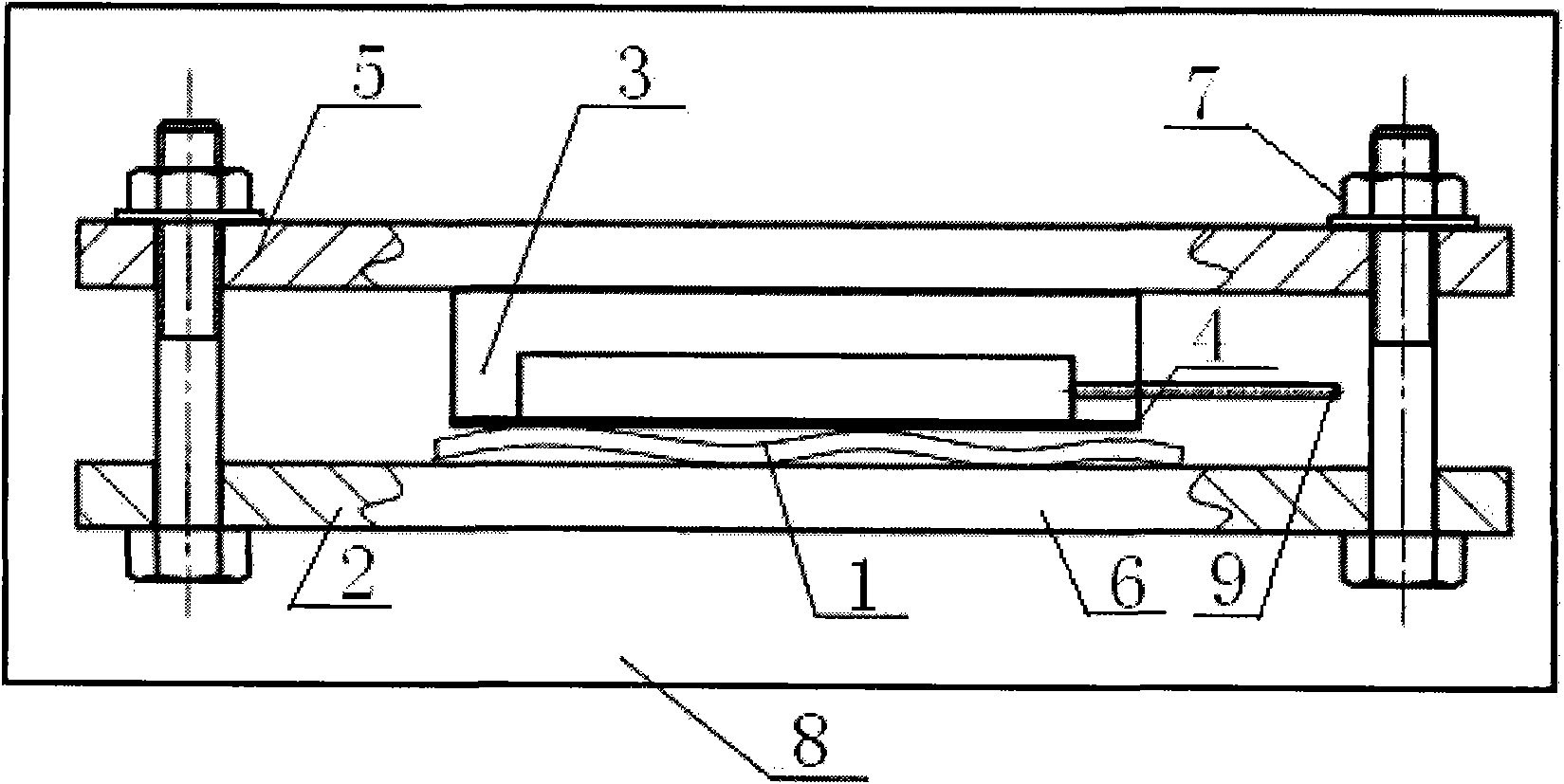

[0022] Such as figure 2 , the low-carbon steel plate 1 to be leveled is placed in the fixture 2, and a sealed air bag 3 is set on the low-carbon steel plate 1. The elastic thin wall 4 of the air bag 3 is in contact with the low-carbon steel plate 1 to be leveled. The gas bag 3 is fastened together with the low-carbon steel plate 1 to be leveled with a clamp, and put into a vacuum annealing furnace 8, vacuumized and heated for annealing, the gas in the gas bag 3 will make the elastic thin-walled 4 Expand toward the low-carbon steel plate 1 to be leveled, and the low-carbon steel plate 1 is annealed to complete the leveling.

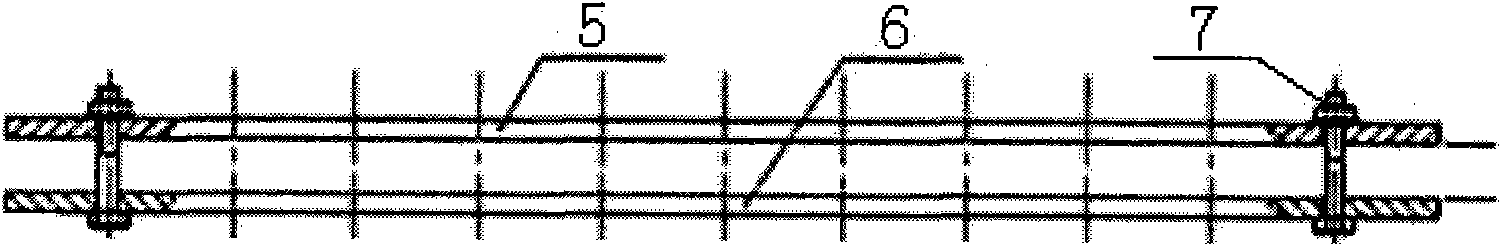

[0023] The fixture 2 as image 3 As shown, including the upper cover plate 5 and the lower cover plate 6, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com