Spring strut arrangement for wheel suspensions of motor vehicles

A technology of wheel suspension and motor vehicle, applied in the direction of vehicle spring, spring, suspension, etc., can solve the problems of large lead screw diameter, unfavorable lead screw rotational inertia, etc., and achieve reduction in radial size, weight, and reduction. The effect of structural space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

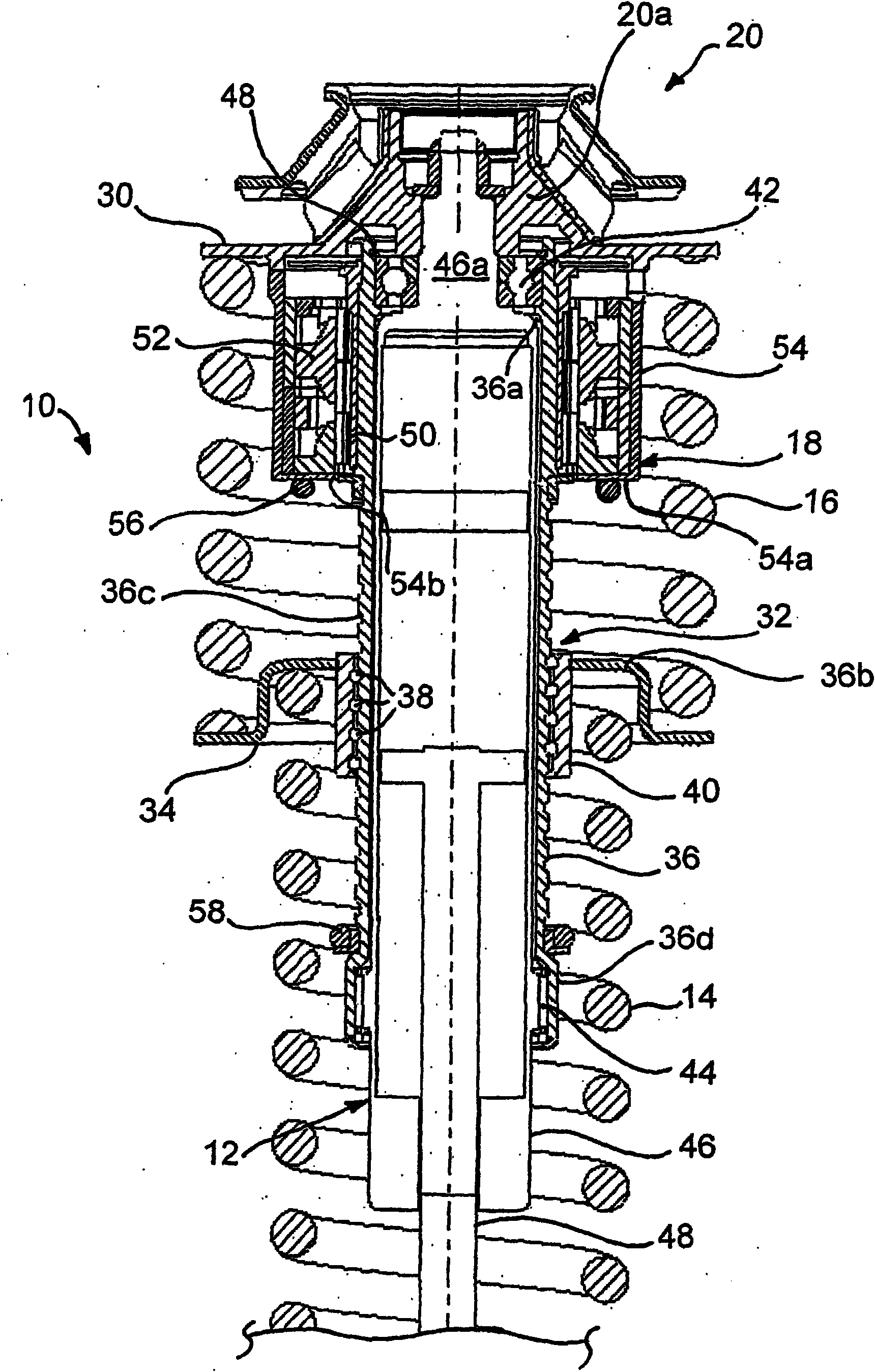

[0034] according to figure 1 The spring strut assembly 10 mainly has a telescopic buffer 12 , a support spring 14 , an auxiliary spring 16 and an electric actuator 18 .

[0035] The upper end of the spring strut arrangement 10 is articulated via a rubber-elastic annular damper bearing 20 to a bodywork 22 (shown only in simplified form) of the motor vehicle. The lower end of the spring strut assembly 10 is hinged to a wheel suspension structural component, such as a pull rod or a wheel hub bracket, through a strut 24 and a rubber-metal sleeve hinge structure 26 .

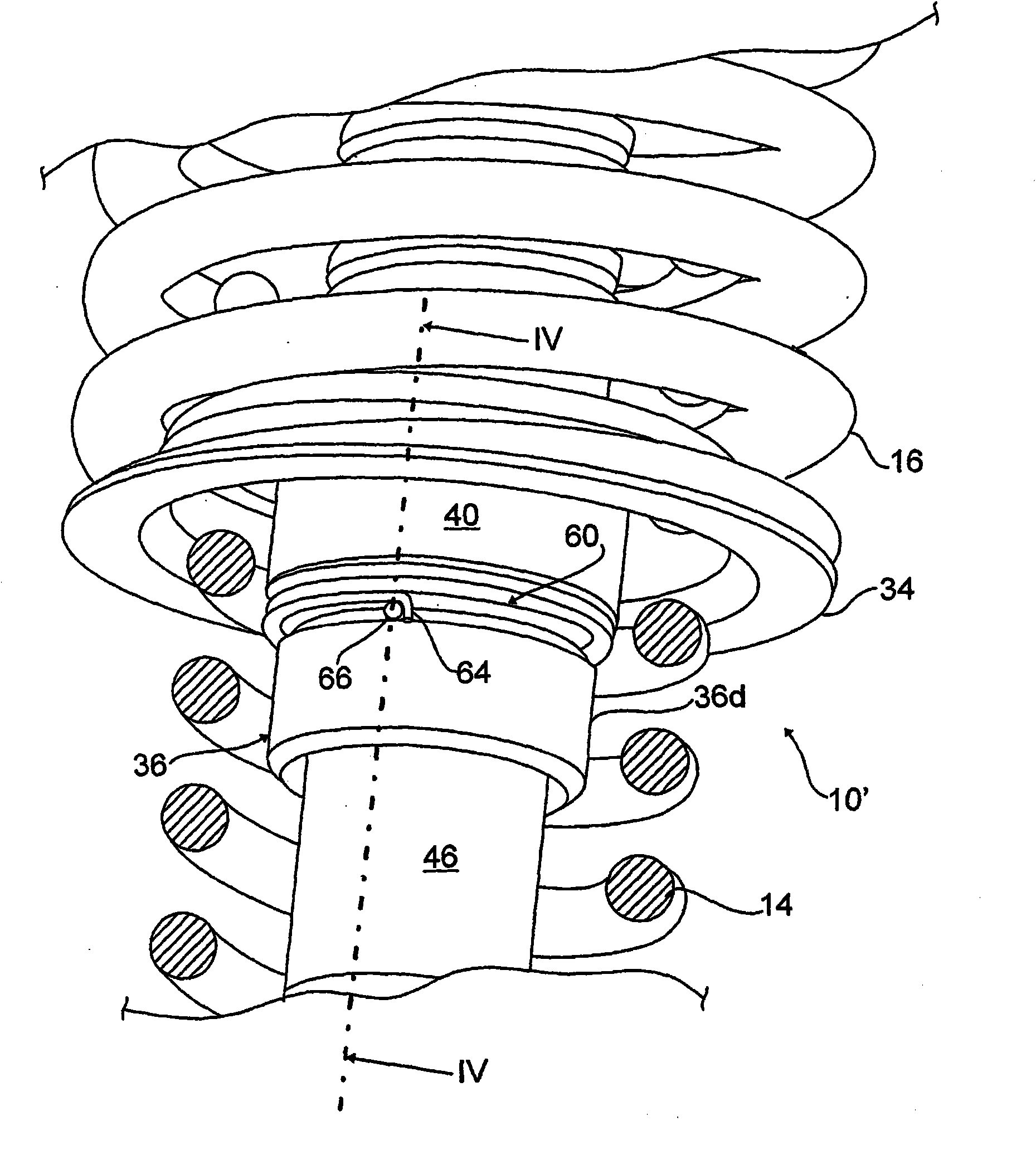

[0036] The supporting spring 14 and the auxiliary spring 16 are designed as helical compression springs (figure ) and are supported via spring washers 28 , 30 on the strut 24 and the vehicle body 22 . Between the supporting spring 14 and the auxiliary spring 16, an adjusting spring seat 34 which can be axially displaced by the adjusting transmission mechanism 32 is arranged, and the supporting spring 14 and the auxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com