Vector multiplication cross engine

An engine and vector technology, which is applied in the direction of engine components, combustion engines, machines/engines, etc., can solve the problems of high manufacturing cost, difficult piston expansion work stroke, and difficulty in large-scale application, so as to improve efficiency and environmental protection, improve thermal The effect of power conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

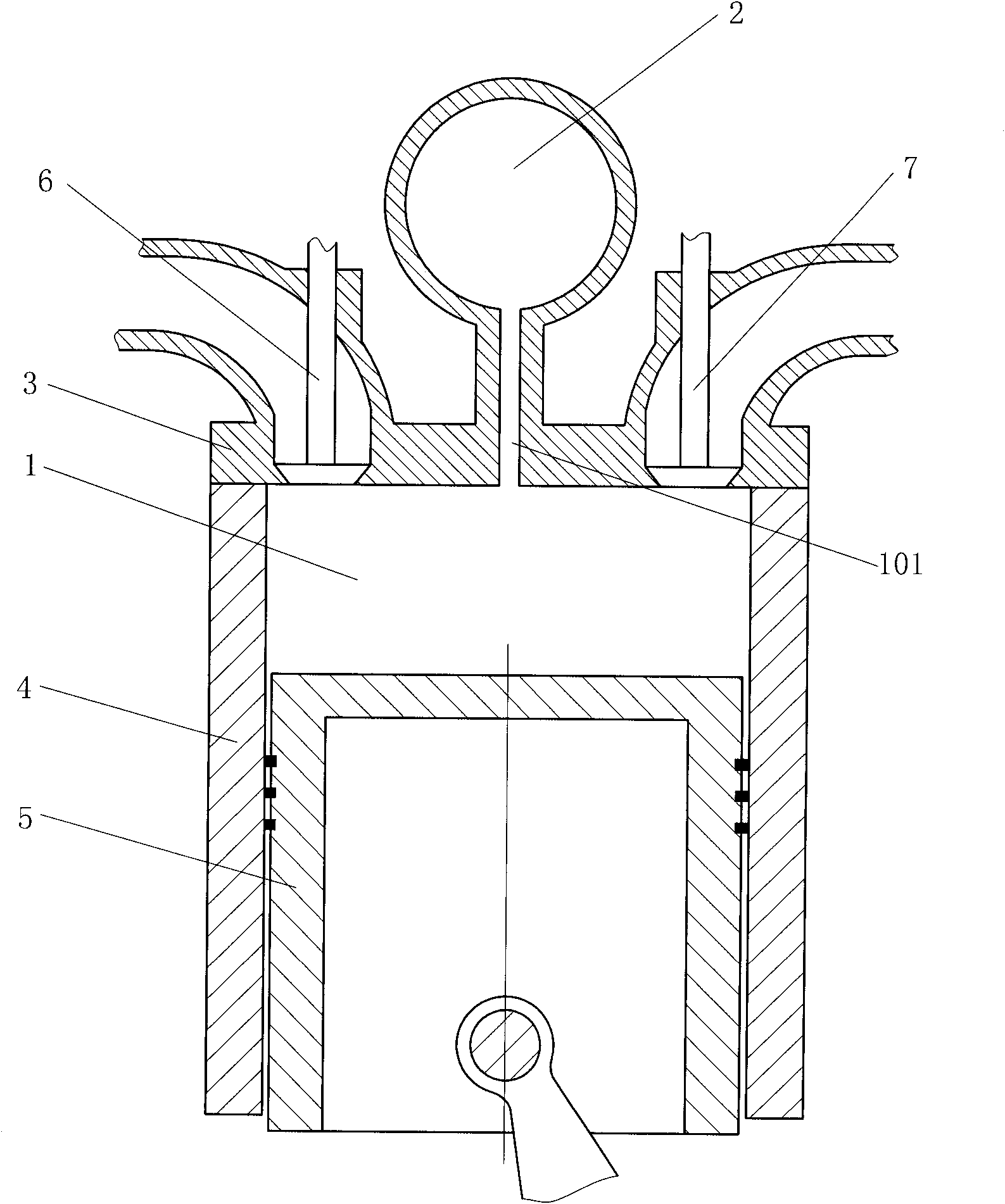

[0072] like figure 1The vector cross-multiply engine shown includes the combustion chamber envelope space 1, and the vector cross-multiply engine also includes a high-pressure working fluid storage tank 2, a cylinder head 3, a cylinder wall 4, a piston 5, an intake valve 6 and an exhaust valve 7, A combustion chamber passage 101 is provided on the outer wall of the combustion chamber enveloping space 1 , and the combustion chamber enveloping space 1 communicates with the high-pressure working medium storage tank 2 through the combustion chamber passage 101 . In this embodiment, the volume of the high-pressure working medium storage tank and the flow resistance of the combustion chamber channel can be adjusted to realize the flow oscillation of the working medium between the combustion chamber envelope space and the high-pressure working medium storage tank, thereby improving the efficiency and efficiency of the engine. environmental purpose. That is, at the moment of combusti...

Embodiment 2

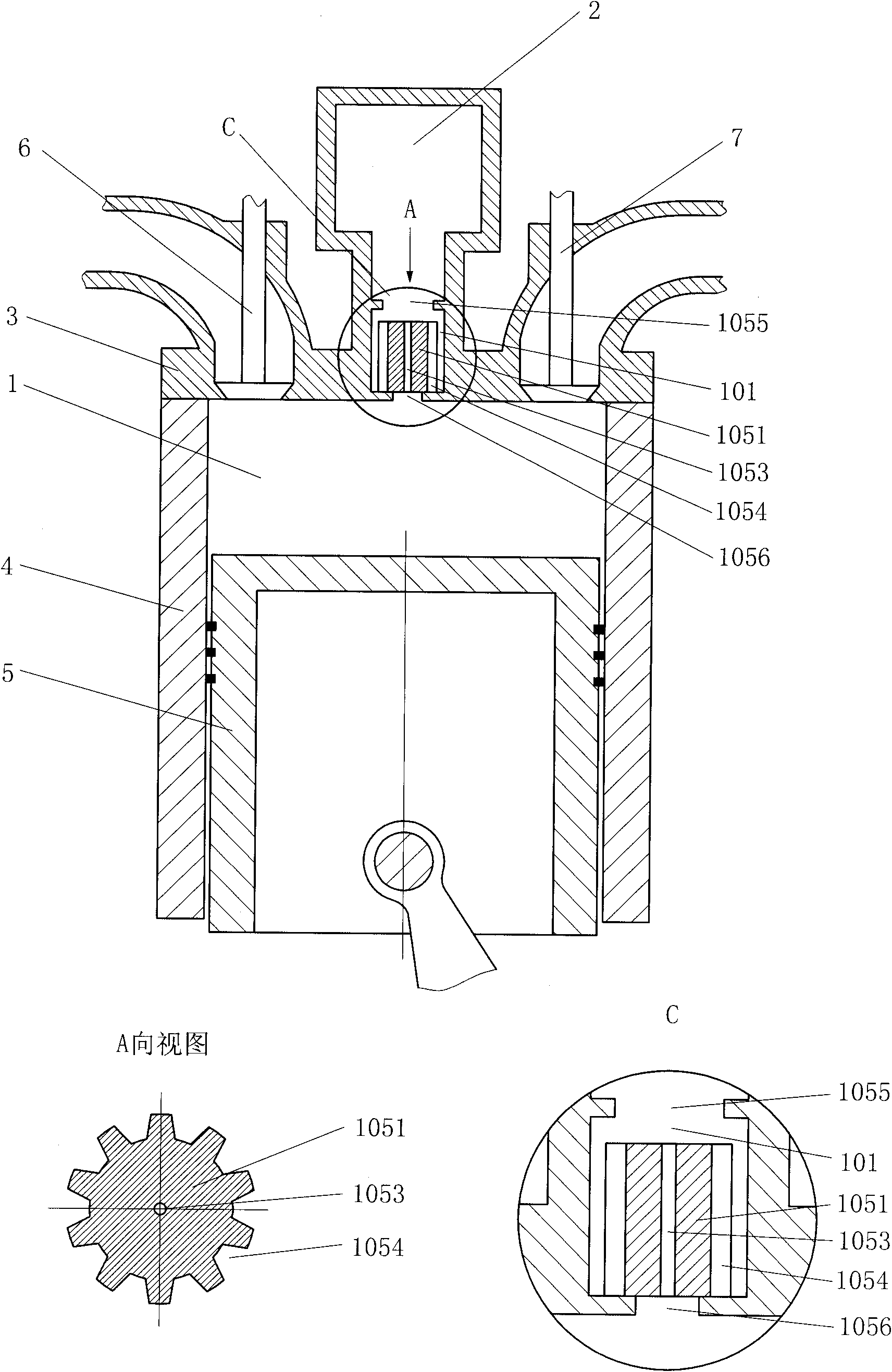

[0074] like figure 2 The difference between the shown vector cross-ride engine and Embodiment 1 is that a sliding structure 1051 is set in the combustion chamber channel 101, and a sliding structure normal passage 1053 and a sliding structure one-way channel are set on the sliding structure 1051. 1054, the normal channel 1053 of the sliding structure and the one-way channel 1054 of the sliding structure pass through the sliding structure 1051 in the direction of connecting the combustion chamber envelope space 1 and the high-pressure working medium storage tank 2, the sliding structure 1051 and the combustion chamber channel 101 Sealed fit or non-sealed fit;

[0075] In the combustor channel 101 near the junction of the combustor channel 101 and the combustor envelope space 1, a small inner diameter end sealing ring 1056 is set, and in the combustor channel 101 near the junction of the combustor channel 101 and the high-pressure working medium storage tank 2 A large inner di...

Embodiment 3

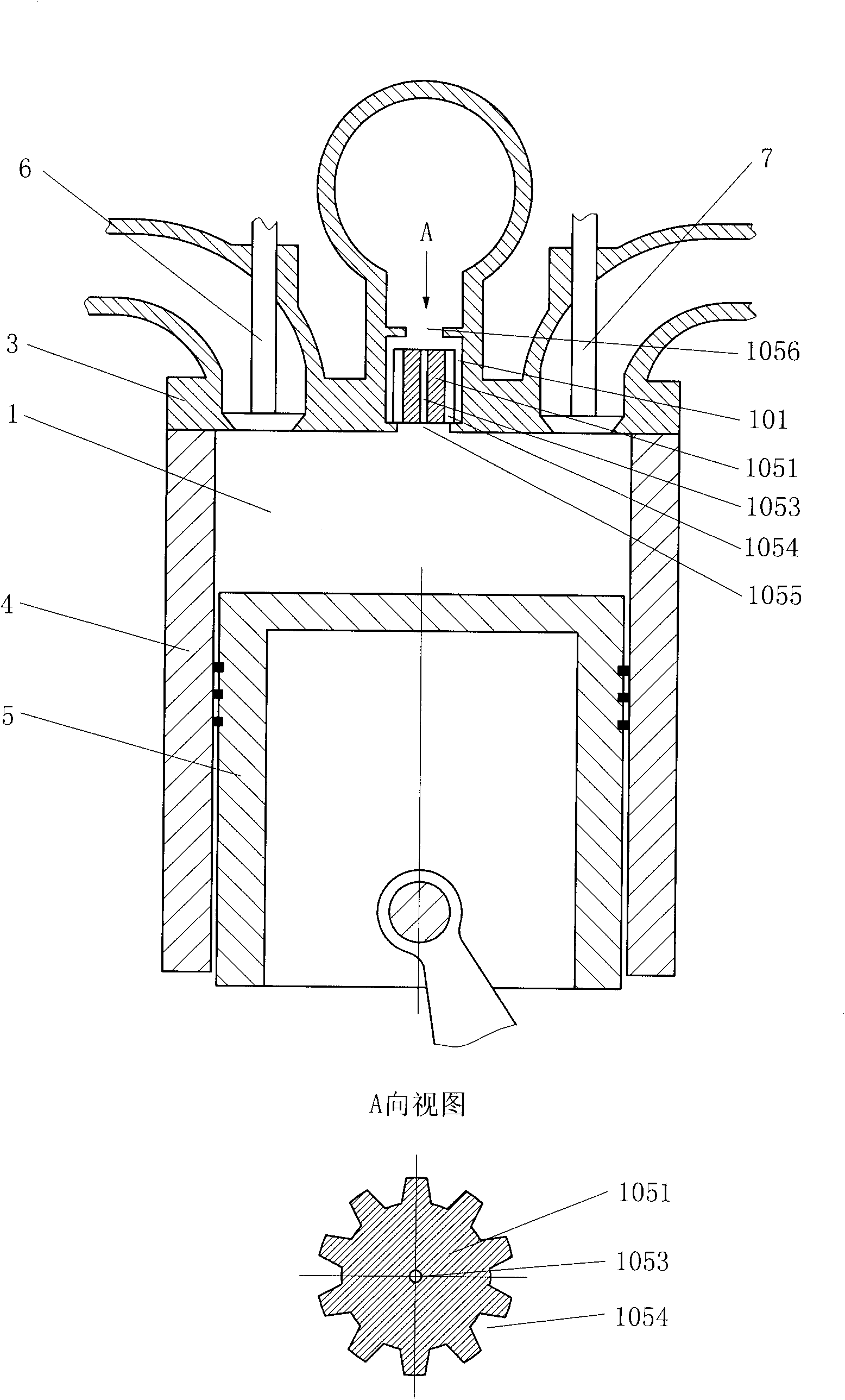

[0077] like image 3 The difference between the shown vector cross-multiply engine and Embodiment 2 is that a large internal diameter end sealing ring 1055 is set in the combustion chamber passage 101 near the junction of the combustion chamber passage 101 and the combustion chamber envelope space 1, A small inner diameter end sealing ring 1056 is provided in the combustion chamber passage 101 near the junction of the passage 101 and the high-pressure working medium storage tank 2 . In this embodiment, the on-off of the channel and / or the flow resistance in different directions are controlled by sliding the sliding structure in the channel, so as to realize the control of the working medium flow between the combustion chamber envelope space and the high-pressure working medium storage tank according to the design requirements .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com