Shield burial method for receiving and plugging overexcavation gap in high-water-pressure stratum

A high water pressure, shield technology, applied in underground chambers, earthwork drilling, wellbore lining, etc., can solve the problems of prone to accidents and high risk of shield receiving, achieve great promotion value and economic benefits, and avoid disasters Effects of Sexual Accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

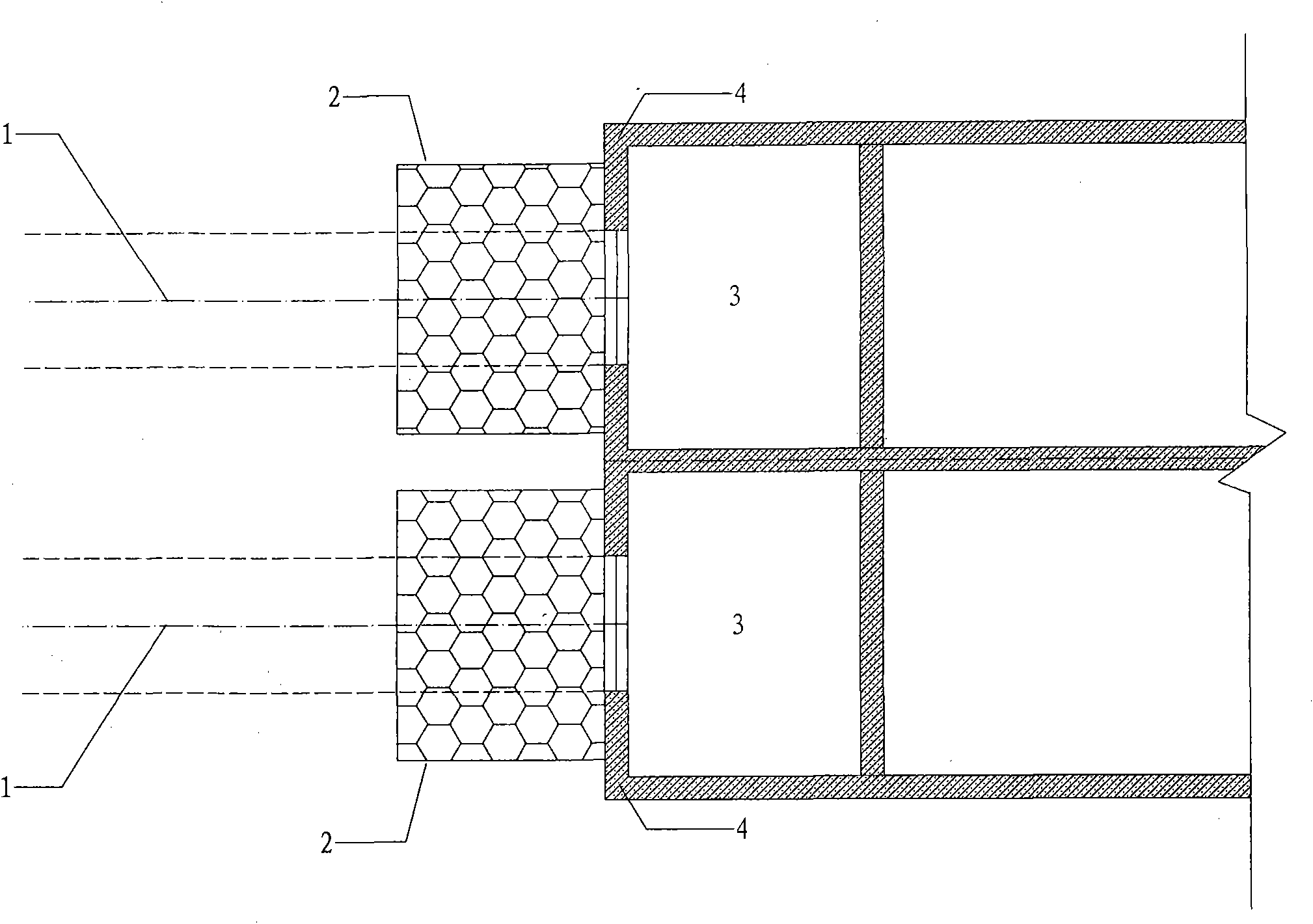

[0027] In order to ensure the safe reception of shield tunneling in high water pressure water-bearing sand formations, submerged shield tunnel reception is required, and a separate space with a size larger than the main body of the shield machine is reserved in advance at the receiving station or during the construction of the station as shield tunnel reception Wells and shield receiving wells must be watertight and able to withstand the external water pressure of the station. The layout of shield receiving wells is as follows: figure 1 shown.

[0028] Before the shield machine arrives (generally 10-20m away from the portal), the concrete and steel bars of the receiving portal are broken, and then a circular groove is chiseled in the portal circle, and a double-layer freezing pipe is laid and fixed in the chiseled circular groove. Freezing pipes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com