Method for diagnosing and processing faults below blast furnace groove

A technology of fault diagnosis and processing method, which is applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve problems such as complex operations, large quantities, and few types of equipment, and achieve low equipment investment, small footprint, and good use effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

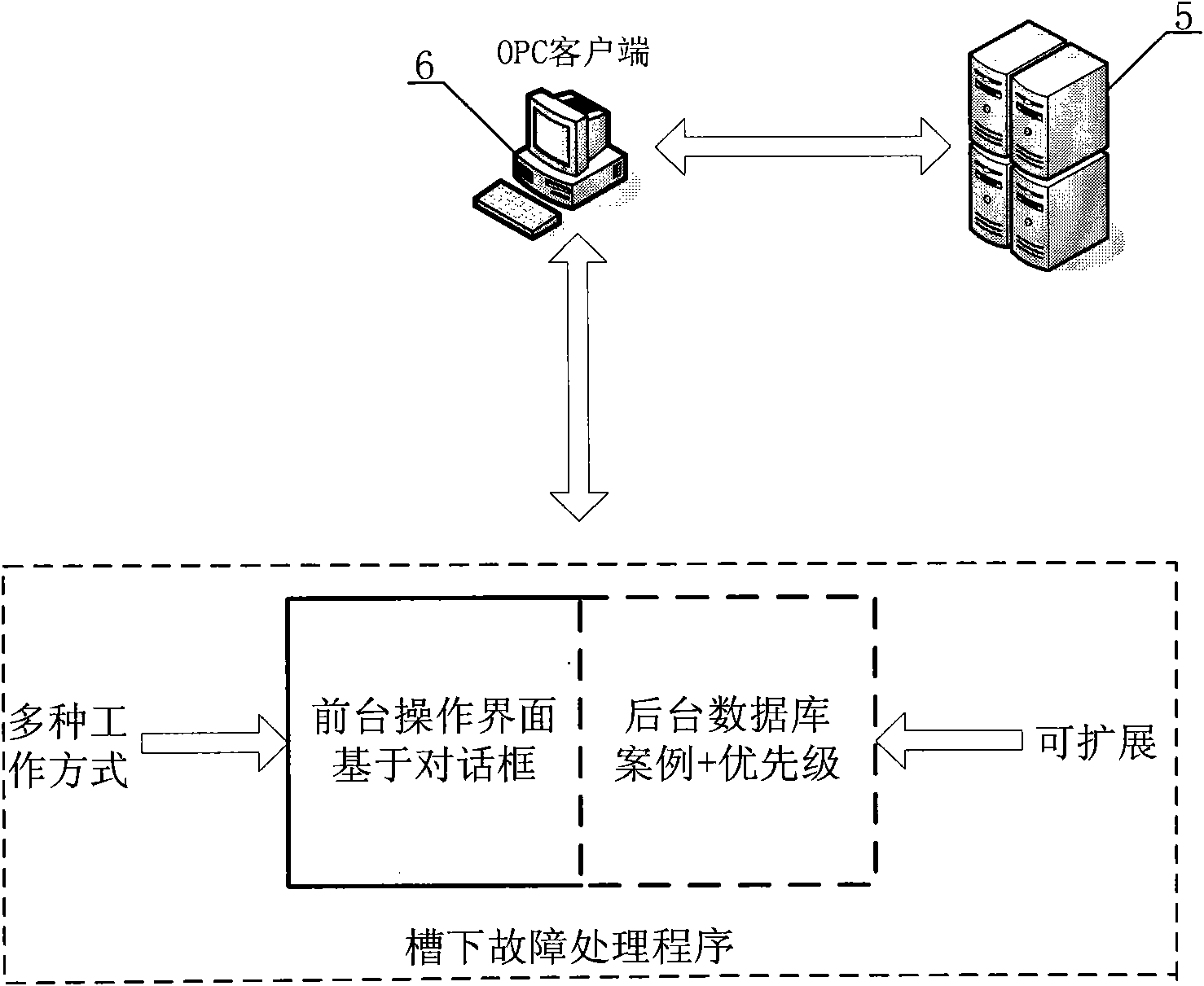

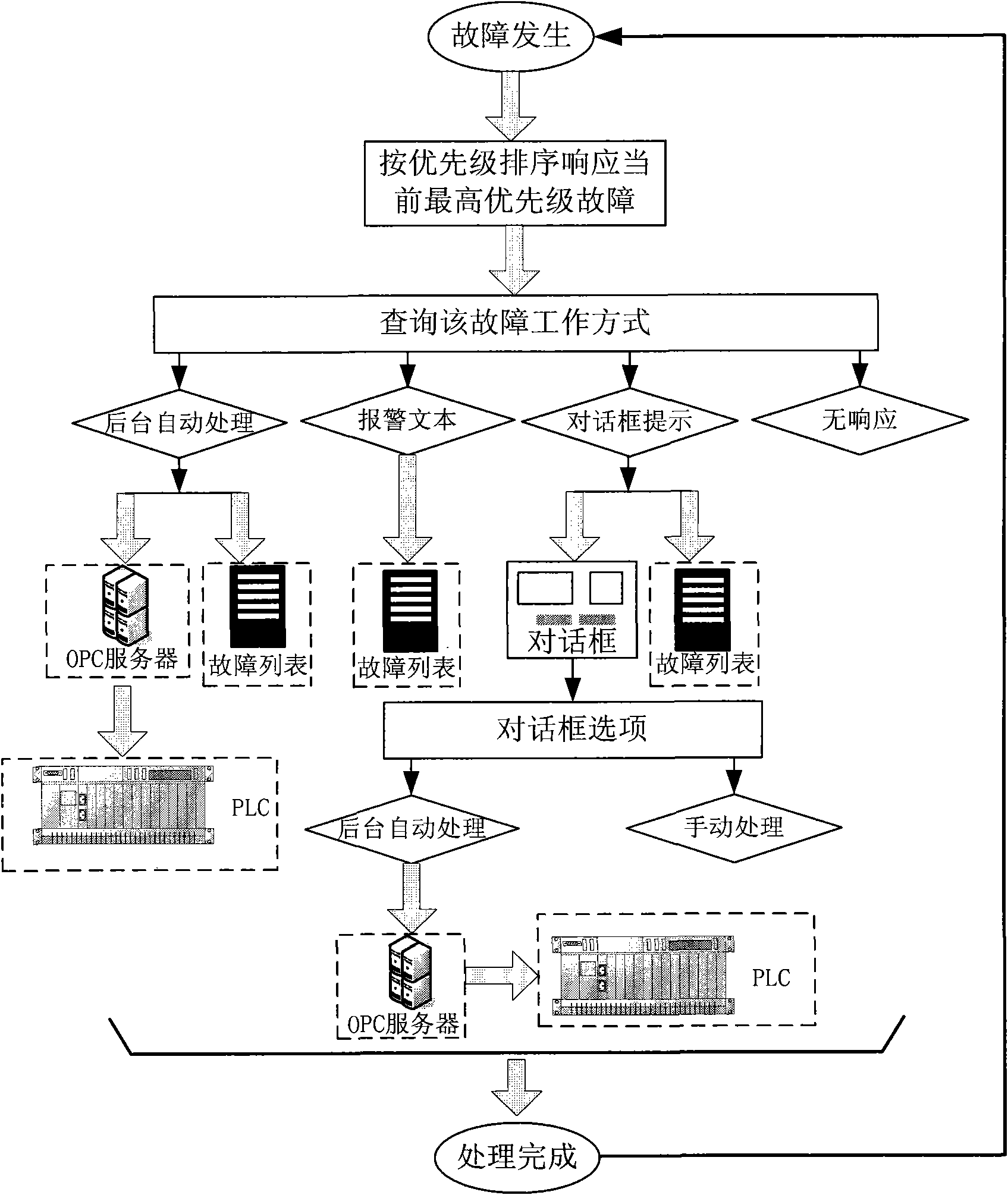

[0011] The fault diagnosis and processing system under the blast furnace tank adopts the OPC (OLE for Process Control) method to communicate with the PLC (programmable logic controller), and manages the fault cases and processing methods through the background database, and the case library is open. needs to be expanded. At the same time, according to the different requirements of operators, the system can provide a variety of processing methods, including fully automatic fault response.

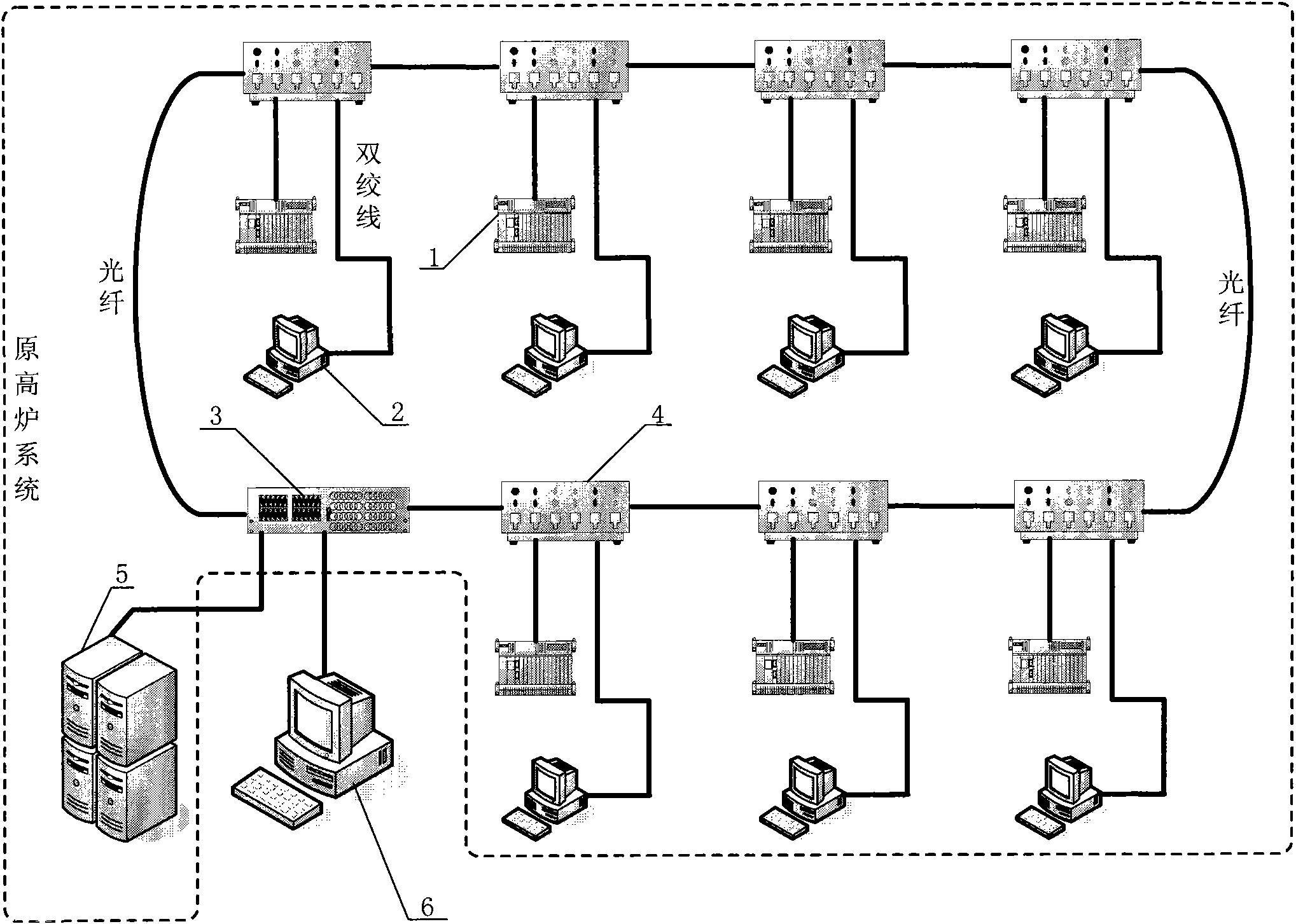

[0012] like figure 1 As shown, the fault diagnosis and processing system under the blast furnace tank includes PLC 1, operation station 2, main switch 3, subsystem switch 4 and OPC server 5, and it also includes fault response PC 6. The connection relationship between them is: the main switch 3 and the subsystem switch 4 form the ring network of the blast furnace, the OPC server 5, the PLC 1 of each system and the operation station 2 are ring network sites, and the fault response PC 6 commu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com