Method for preparing liquefied natural gas by utilizing relief gas of methanol

A technology of methanol degassing and liquefied natural gas, which is applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problems of inability to use gas, poor economic benefits, and inability to be fully utilized, so as to save energy, protect the environment, and increase products. The effect of diversity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

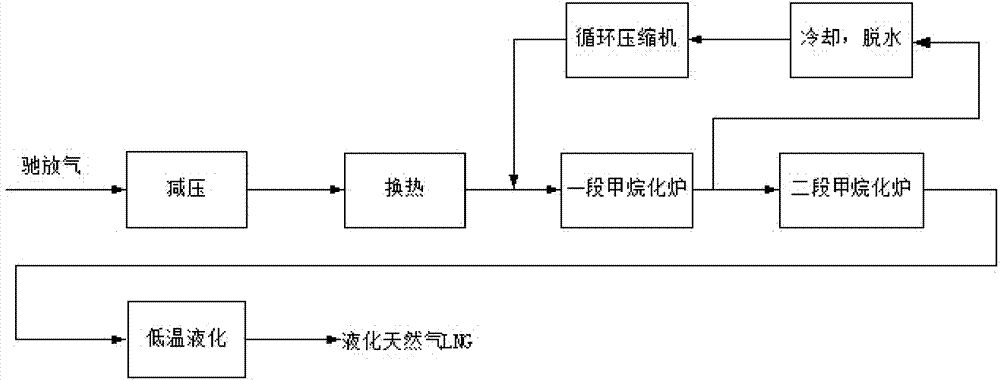

[0038] Such as figure 1 As shown, the method for preparing synthetic natural gas alkane by utilizing coal-to-methanol purge gas in this embodiment includes the following main steps:

[0039](1) The composition of the coal-to-methanol purge gas is shown in Table 1. The coal-to-methanol purge gas was decompressed to 3.0 MPa, and the heat was exchanged to about 250°C.

[0040] (2), one-stage methanation reaction: the coal-to-methanol purge gas and the recycle gas generated later are mixed and heated and then enter the first-stage methanation furnace, and the molar ratio of the recycle gas to the purge gas entering the first-stage methanation furnace is 1 : 1, under the action of nickel-based catalyst, carry out one-stage methanation reaction; After one-stage reaction, the temperature of reactor outlet is 610 ℃, and wherein nickel-based catalyst is 20% NiO; 70% Al 2 o 3 And 20% MgO, all are mass ratio;

[0041] (3) Second-stage methanation reaction: the synthesis gas after the ...

Embodiment 2

[0044] In this embodiment, the method for synthesizing methane by using coal-to-methanol purge gas includes the following main steps:

[0045] (1) The composition of the coal-to-methanol purge gas is shown in Table 1. The coal-to-methanol purge gas is decompressed to 4.0MPa and heat exchanged to about 320°C;

[0046] (2), one-stage methanation reaction: coal methanol purge gas and circulating gas are mixed and heated and then enter the first-stage methanation furnace, and the molar ratio of the recycle gas and the purge gas entering the first-stage methanation furnace is 4:1, , under the action of a nickel-based catalyst, a first-stage methanation reaction is carried out; after the first-stage reaction, the temperature at the outlet of the reaction furnace is 427°C; the nickel-based catalyst is 10% NiO; 50% Al 2 o 3 And 40% MgO, all are mass ratio;

[0047] (3) Second-stage methanation reaction: the synthesis gas after the first-stage methanation reaction is cooled to 400°C ...

Embodiment 3

[0050] In this embodiment, the method for synthesizing methane by using coal-to-methanol purge gas includes the following main steps:

[0051] (1) The composition of the coal-to-methanol purge gas is shown in Table 1. The coal-to-methanol purge gas is decompressed to 5.0MPa, and the heat is exchanged to about 290°C;

[0052] (2), one-stage methanation reaction: coal-based methanol purge gas and circulating gas are mixed and heated, mixed with water vapor and then enter the first-stage methanation furnace, and the molar ratio of the recycle gas to the purge gas entering the first-stage methanation furnace is 2:1, under the action of a nickel-based catalyst, a first-stage methanation reaction is carried out; after the first-stage reaction, the temperature at the outlet of the reaction furnace is 475°C, wherein the nickel-based catalyst is 5% NiO; 45% Al 2 o 3 And 50% MgO, all are mass ratio;

[0053] (3) Second-stage methanation reaction: the synthesis gas after the first-stag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com