Automatic guided vehicle for manufacturing process of thin film solar battery

A technology for unmanned trucks and solar cells, applied in the field of unmanned trucks, can solve the problems of difficult access and transfer of large-sized substrates, reduce the possibility of substrate damage, reduce weight and handling costs, and increase stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

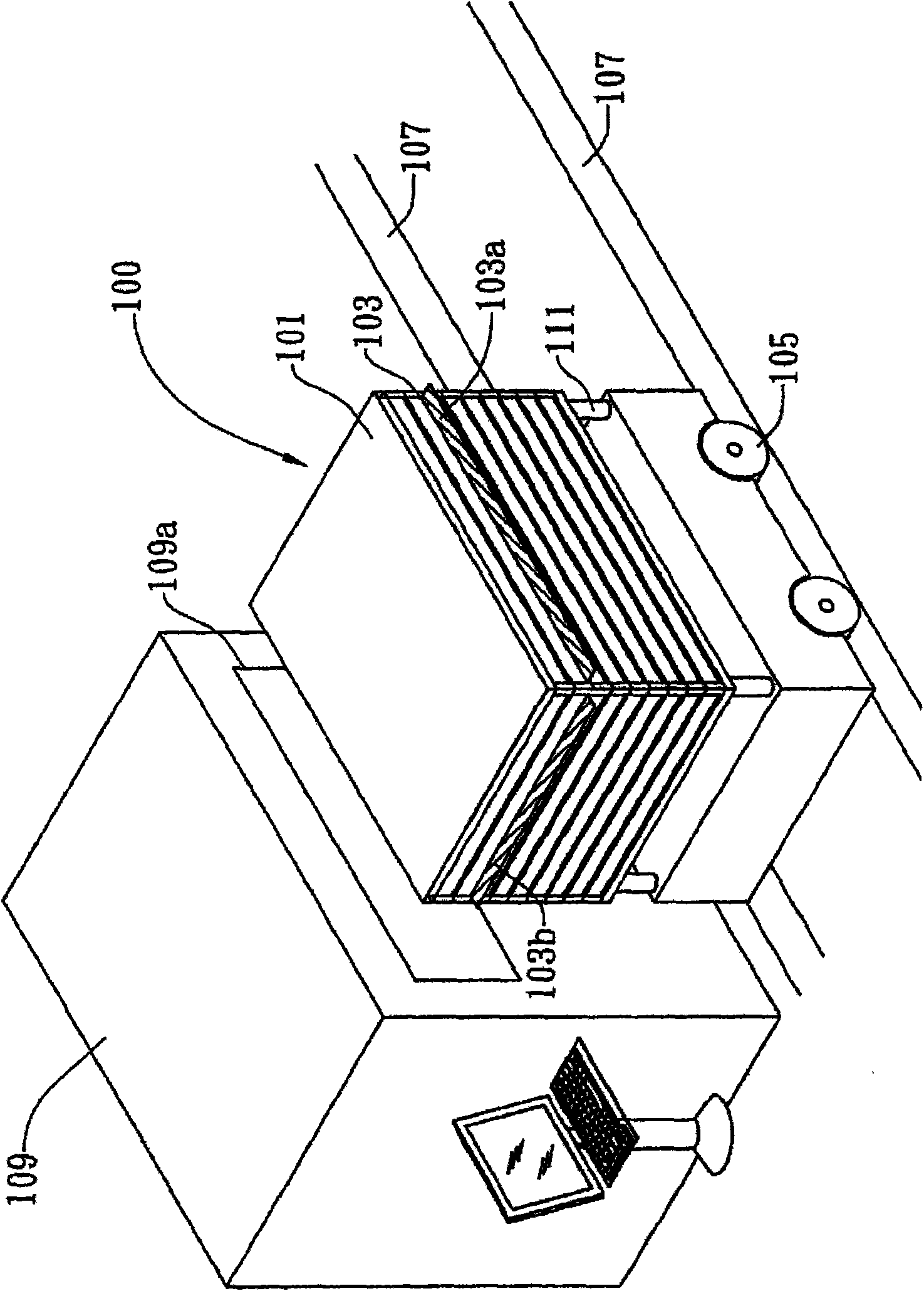

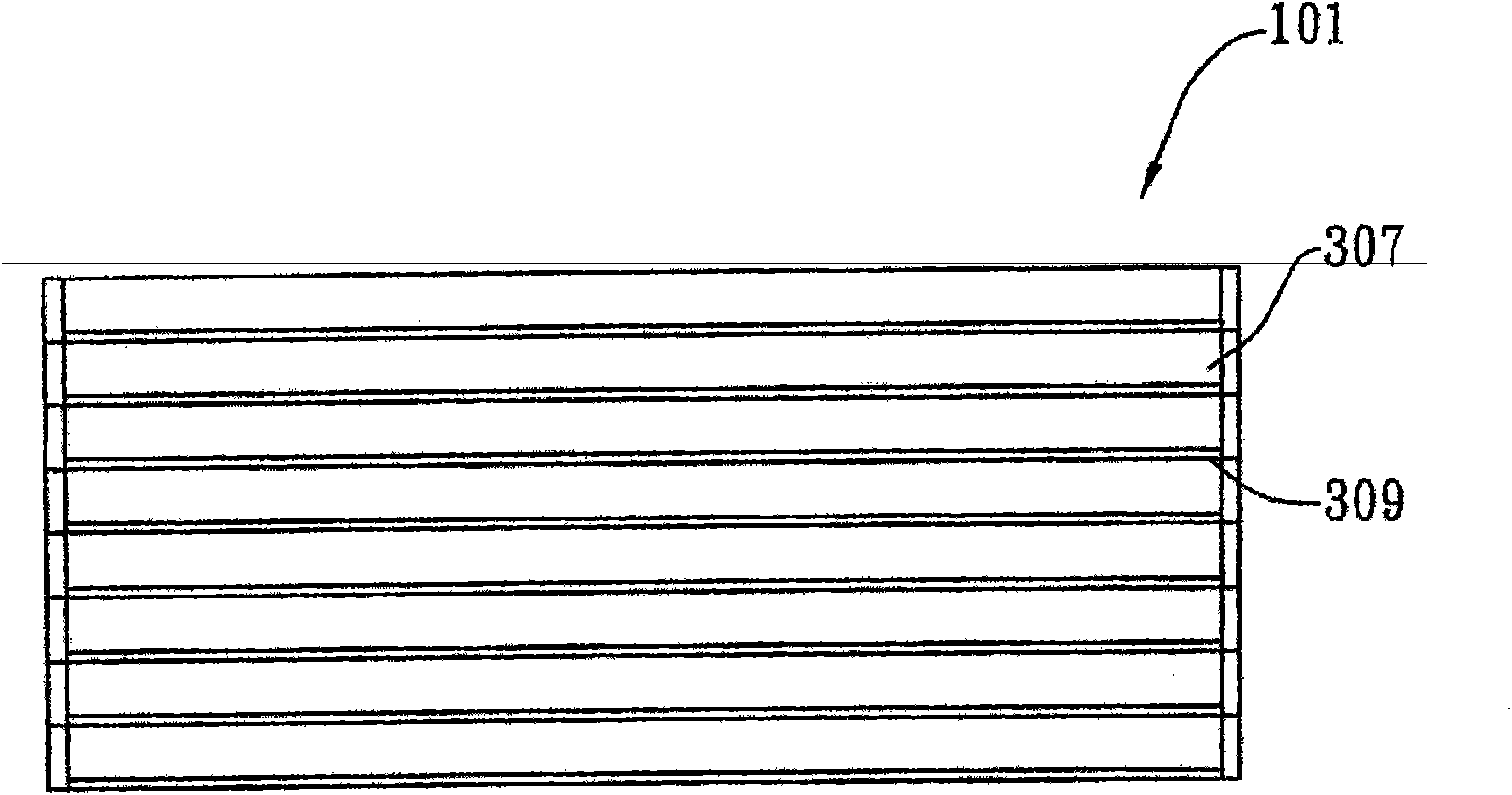

[0035] now refer to figure 1, which is a schematic diagram of an unmanned guided vehicle of the present invention. As shown in the figure, the unmanned guided vehicle 100 of the present invention includes a frame 101 composed of a plurality of storage compartments 103 for placing thin-film solar cell substrates. The storage compartments 103 are arranged in a horizontally stacked manner, and each storage compartment 103 can place and fix a whole substrate, and outlets 103a and 103b are respectively provided on the length and width sides of the frame for the substrate to move in two directions. Load load out. The unmanned guided vehicle 100 has a transmission mechanism 105, which is arranged under the frame 101, and is used to mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com