Multi-color-register automatic printing interprocess drying machine

A technology of inter-process and drying machine, which is applied to printing machines, general parts of printing machinery, printing, etc., can solve the problems of increased production cost, large power load, and high power consumption, and achieve low cost of use and reasonable structure , Improve the effect of drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

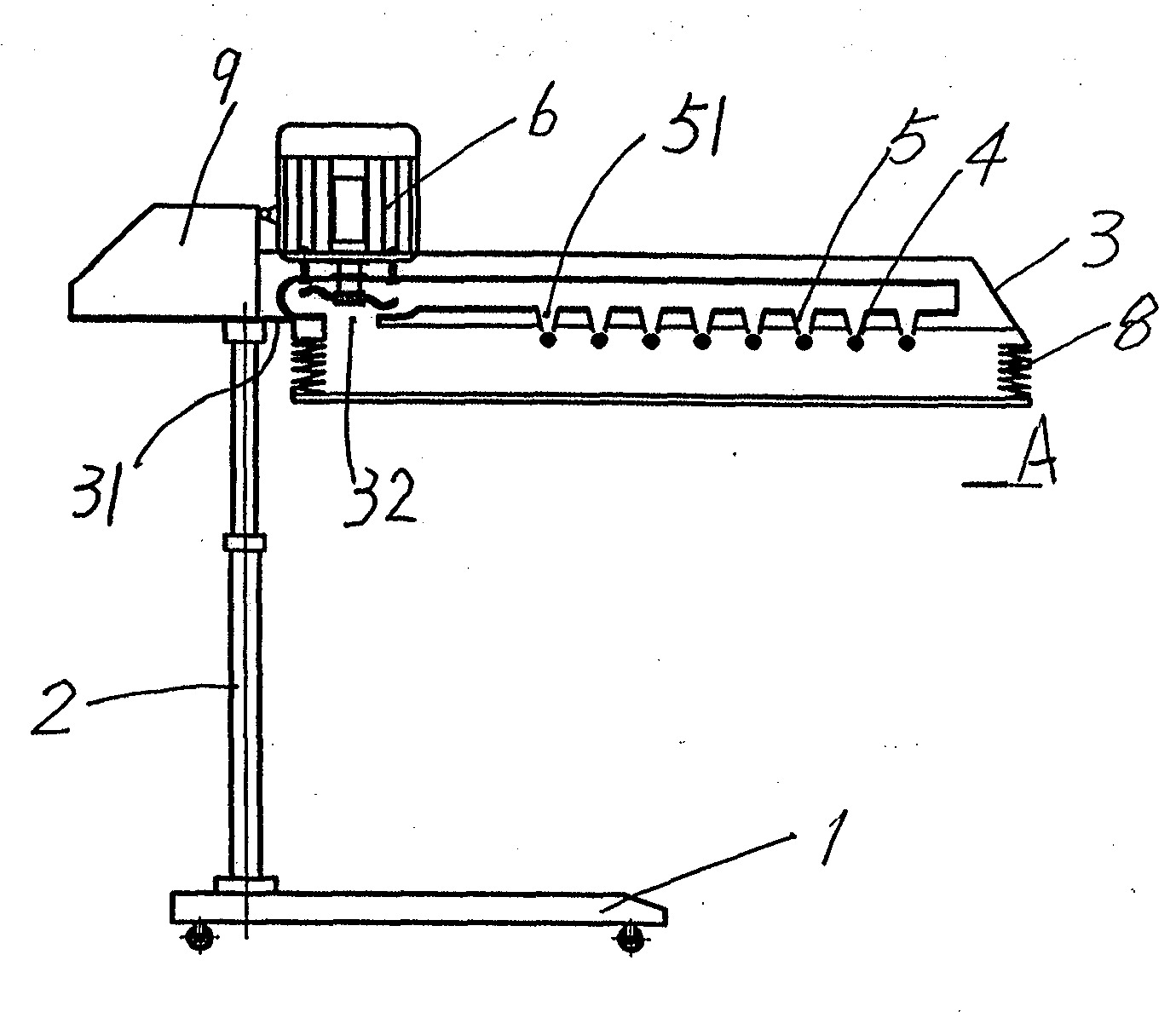

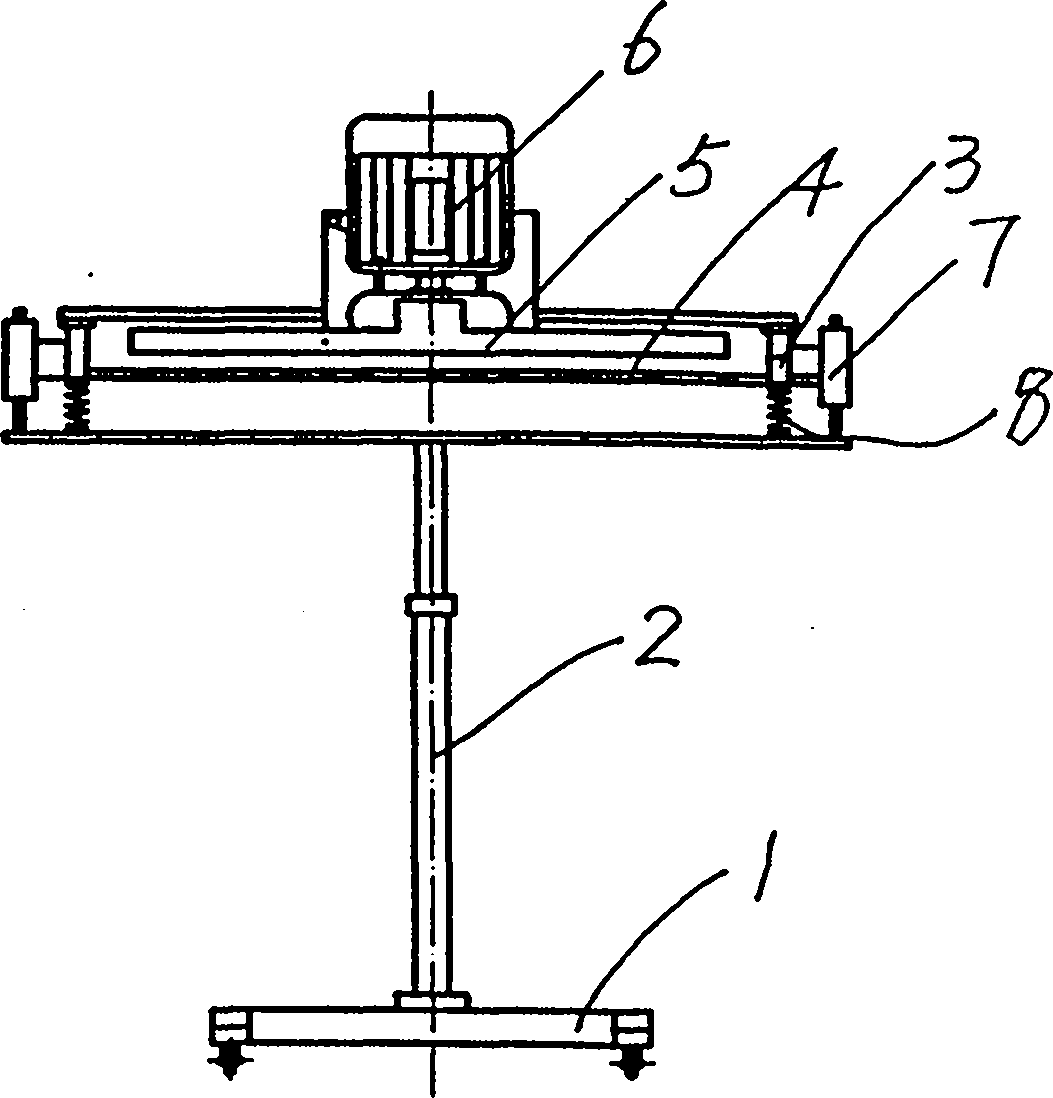

[0014] Refer to attached figure 1 , with figure 2 , the multi-color automatic printing process drying machine of the present invention is composed of a base 1, a pillar 2, a frame 3, a heating component 4, an air duct device 5, a fan 6, a pneumatic device 7, an elastic sealing device 8, and a control device 9. A pillar 2 is arranged on the base 1, a frame 3 is arranged on the pillar 2, and at least one set of heating elements 4 are arranged on the frame 3, eight sets are provided in this embodiment, and the heating elements 4 are electric heating devices. Also be provided with air channel device 5 on frame 3, described frame 3 is made up of frame frame 31, air inlet 32, and air inlet 32 communicates with air channel device 5; Air channel device 5 links to each other with blower fan 6, and described The air duct device 5 is an air supply duct device provided with at least one set of air outlets 51, eight groups of air outlets in this embodiment; an elastic sealing device 8 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com