Water-based zircon powder quick drying paint for ultra-large steel casting

A technology of zircon powder and steel castings, applied in the field of foundry coatings, can solve the problems of increased production process and energy waste, insufficient safety of alcohol-based coatings, prolonging the production cycle, etc., to promote water migration and accelerate curing speed , The effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

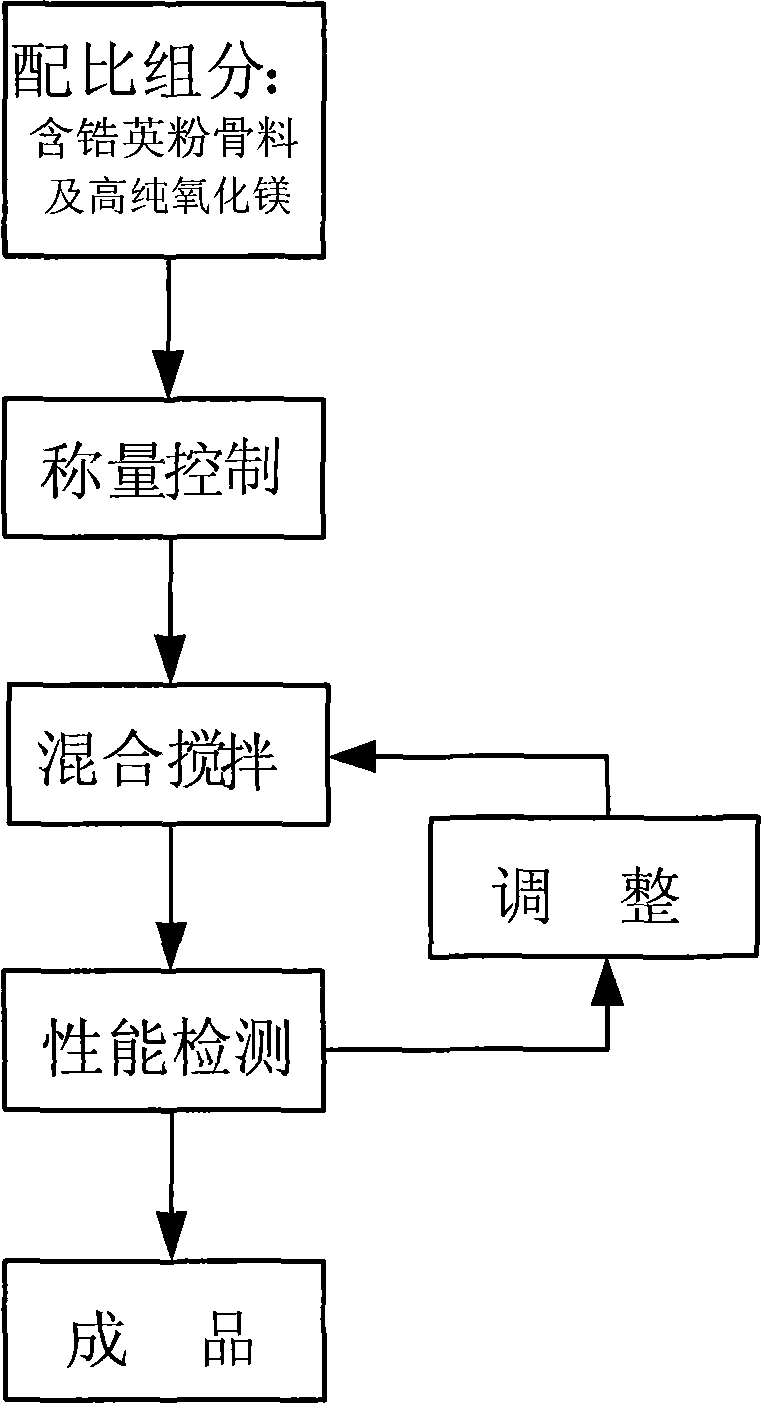

[0013] figure 1 The preparation process of the water-based zircon powder quick-drying coating of the present invention is shown.

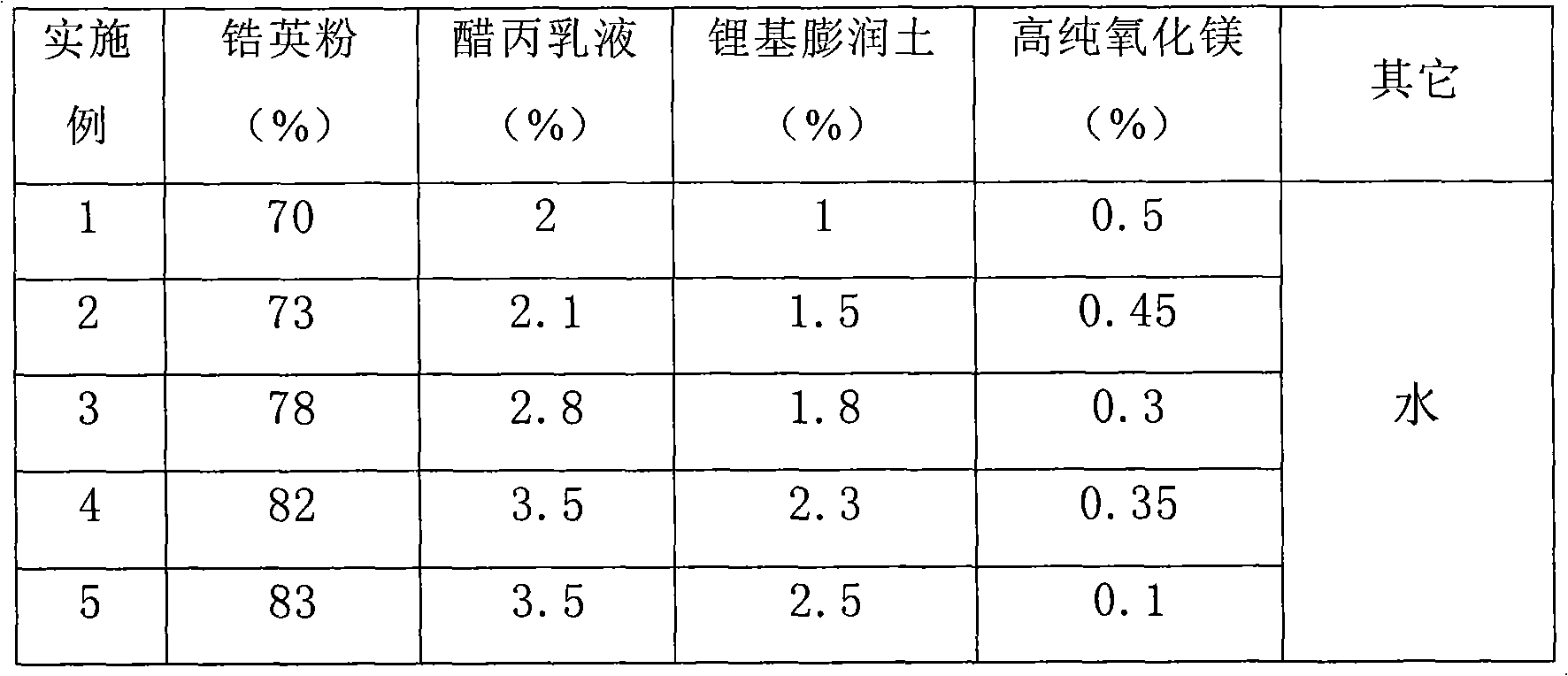

[0014] The water-based zircon powder quick-drying coating suitable for super-large steel castings, which has obtained the best performance, coating performance and quick-drying performance after a large number of tests, its weight percentage ratio is:

[0015] Zircon powder 70-83%, vinegar-acrylic emulsion 2-3.5%, lithium-based bentonite 1-2.5%, high-purity magnesium oxide (MgO content greater than 99%) 0.1-0.5%, and the rest is water.

[0016] 1. First prepare composite refractories according to the table below:

[0017]

[0018] 2. Weighing control

[0019] Weigh the raw materials of each component of the coating according to the proportioning dosage.

[0020] 3. Mix and stir

[0021] When adding materials, pay attention to adding water, lithium-based bentonite (suspension agent), vinegar-acrylic emulsion (binder) and high-purity magnesium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com