Continuous rheomolding device for manufacturing metal plate strips

A rheological forming, metal strip technology, applied in metal rolling and other directions, can solve the problems of slow continuous casting and rolling speed, low cooling intensity, slow casting and rolling speed, etc., and achieve high-efficiency, energy-saving production and heat dissipation performance. Good, improve the effect of tissue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

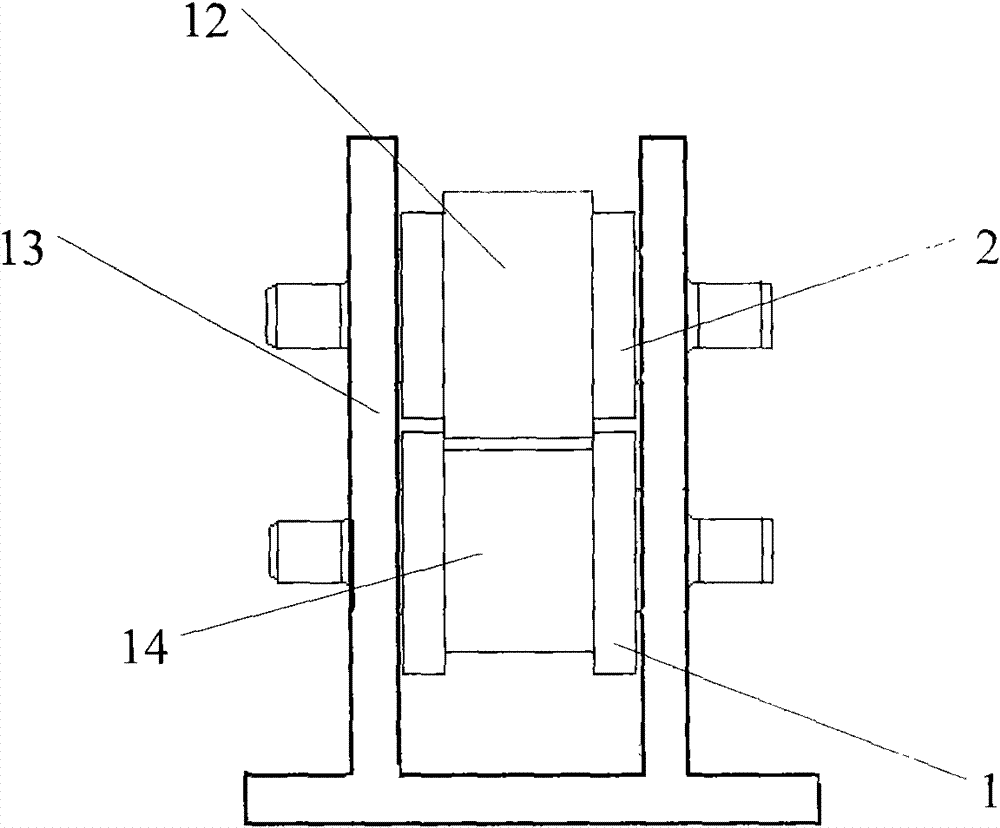

[0028] The structure of the continuous rheological forming device for preparing metal strips is as follows: figure 1 As shown, the device includes an inclined plate, a base 7, an electromagnetic exciter 9 and a two-roll rolling mill. The inclined plate is composed of a feeding section 5, a pulping section 4 and a discharging section 3 connected in sequence, and each section includes a bottom plate and two side plates; the bottom plate of the pulping section is wave-shaped, the bottom of the wave-shaped pulping section bottom plate 15 is connected with the upper end of the spring 6, the lower end of the spring 6 is fixed on the base 7, and one end of the electromagnetic exciter 9 is fixed On the base 7, the other end is connected with the bottom plate of the pulping section 4, and the outlet end of the discharge section 5 is close to the two-roll mill, and the bottom plate and two side plates of the discharge section 5 are connected with the upper roll 1 and the bottom of the tw...

Embodiment 2

[0039] The structure of the continuous rheological forming device for preparing metal strips is the same as in Example 1, the difference is that:

[0040] There is a gap of 1.0 mm between the outlet end of the discharge section and the arc surface of the upper roll, the arc surface of the lower roll, the arc surface of the annular groove and the side of the annular groove.

[0041] The height of the annular boss is smaller than the depth of the annular groove, and the difference between the two is 1.5mm;

[0042] The angle between the bottom surface of the feeding section and the horizontal plane is 50°, and the angle between the pulping section and the feeding section is 140°;

[0043] The top surface of the bottom plate of the pulping section is flat.

[0044] The material of the inclined plate is stainless steel, and the top surface of each section of the inclined plate is closed and provided with a top plate.

[0045] The method of use is the same as in embodiment 1, exc...

Embodiment 3

[0047] The structure of the continuous rheological forming device for preparing metal strips is the same as in Example 1, the difference is that:

[0048] There is a gap of 1.2 mm between the outlet end of the discharge section and the arc surface of the upper roll, the arc surface of the lower roll, the arc surface of the annular groove and the side of the annular groove.

[0049] The height of the annular boss is less than the depth of the annular groove, and the difference between the two is 5mm;

[0050] The angle between the bottom surface of the feeding section and the horizontal plane is 70°, and the angle between the pulping section and the feeding section is 160°;

[0051] The top surface of the bottom plate of the pulping section is wave-shaped, the distance between adjacent wave peaks is 45mm, the distance between adjacent wave peaks and wave troughs is 15mm, and the height difference between adjacent wave peaks and wave troughs is 5mm.

[0052] The method of use i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com