Separation system and method for high-temperature and high-pressure complex fluid

A high-temperature, high-pressure, separation system technology, applied in separation methods, chemical instruments and methods, immiscible liquid separation, etc., to achieve the effects of easy implementation, simple structure, and wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

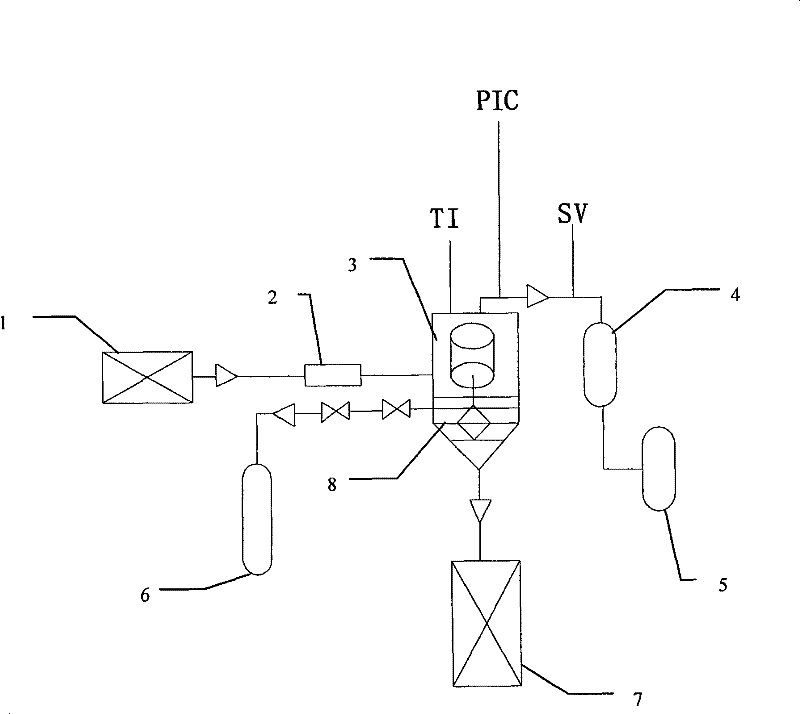

[0039] Several exemplary embodiments of the present invention will be described below with reference to the accompanying drawings.

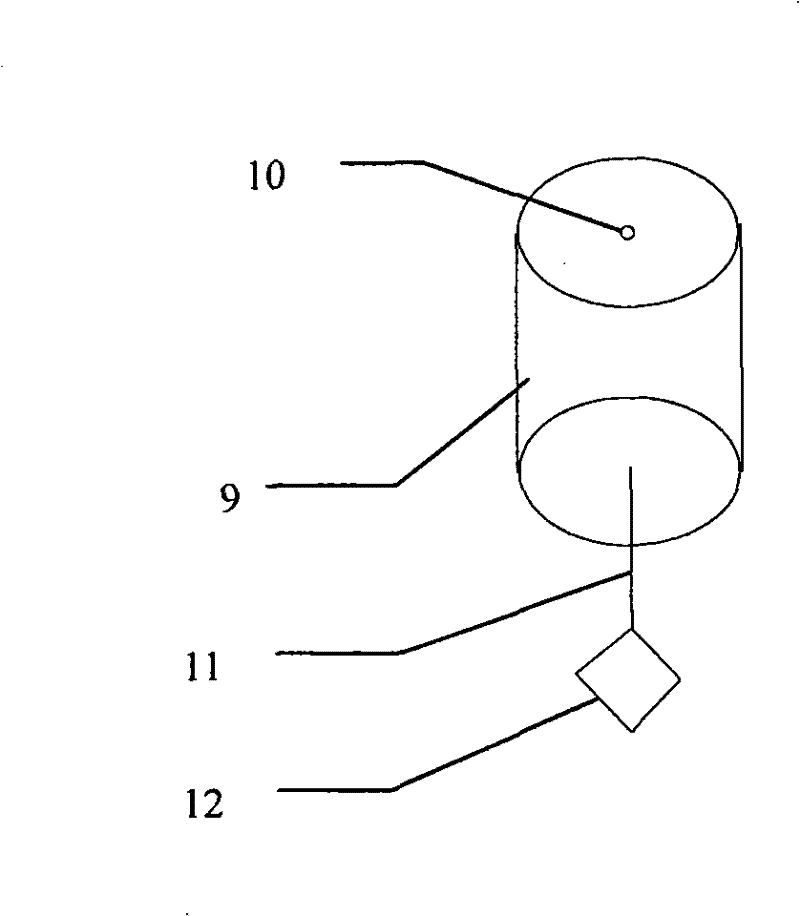

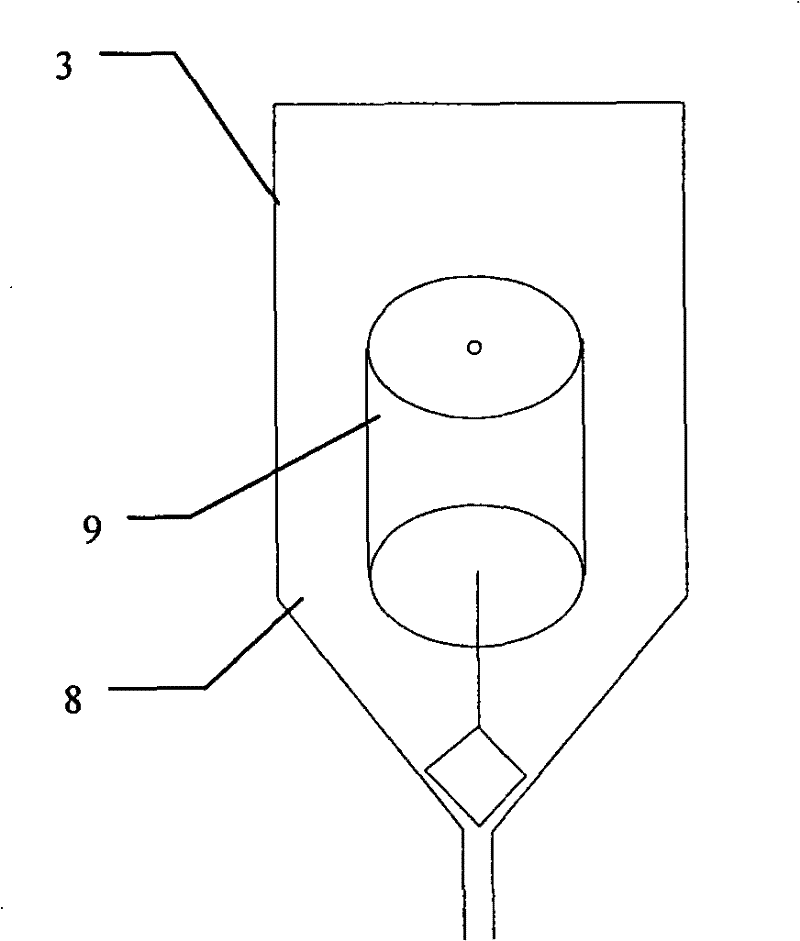

[0040] The present invention provides a high temperature and high pressure complex fluid separation system, the system includes: a first reactor 1, the first reactor 1 is a carbon-containing compound supercritical solvent extraction or gasification reactor; The first separator 3 downstream of the first reactor 1, the first separator 3 has: the gas phase product outlet pipeline at the top of the first separator 3, in a preferred implementation of the separation system of the present invention In the mode, a first heat exchanger 2 is connected through a pipeline between the first reactor 1 and the first separator 3; the downstream of the gas phase product outlet pipeline is connected to the second heat exchanger 4 , the downstream of the second heat exchanger 4 is connected to the second separator 5; the liquid phase product outlet pipeline positio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com