Method for forming through holes on base material and base material with through holes

A technology of through-holes and substrates, which is applied in semiconductor devices, semiconductor/solid-state device manufacturing, semiconductor/solid-state device components, etc., and can solve problems such as incomplete consistency, inconsistent capacitance, and uneven thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

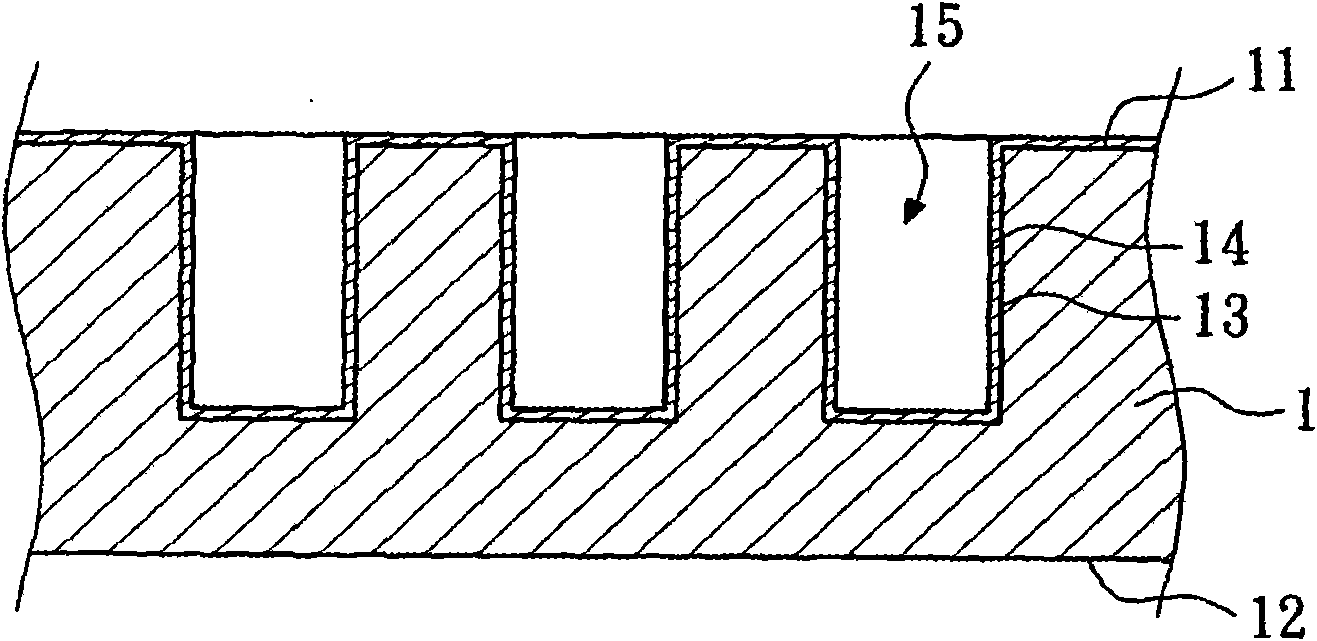

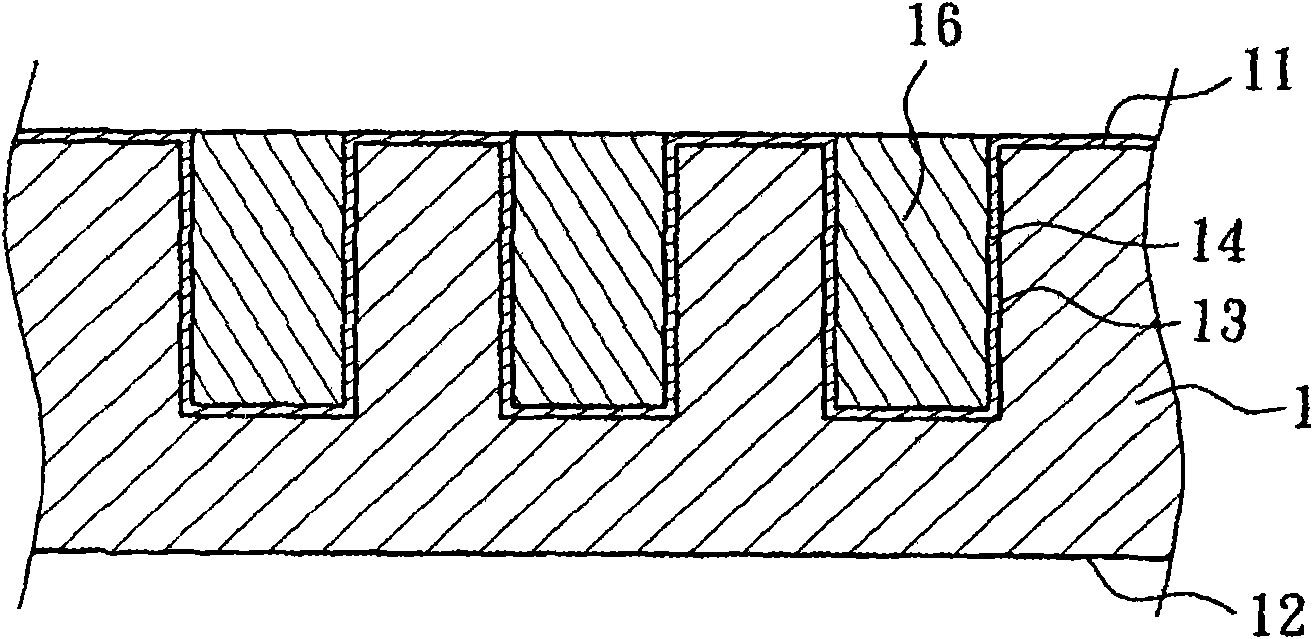

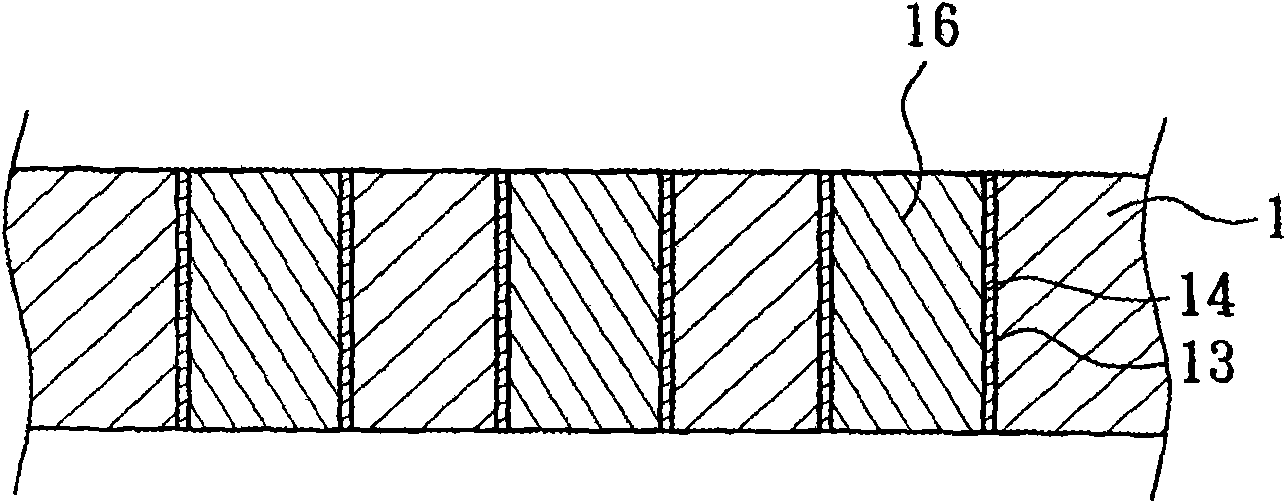

[0105] reference Figure 4 to Figure 21 , Showing a schematic diagram of the first embodiment of the method for forming via holes on a substrate of the present invention. First, refer to Figure 4 and Figure 5 ,among them Figure 4 Is the top view of the substrate, Figure 5 for Figure 4 Section along line 5-5 in the middle. A substrate 21 is provided, and the substrate 21 has a first surface 211 and a second surface 212. The substrate 21 can be a silicon substrate or a wafer. Next, a slot 231 is formed on the first surface 211 of the substrate 21. The slot 231 has a side wall 232 and a bottom surface 233. In this embodiment, a first photoresist layer 241 is formed on the substrate 21. The first surface 211 is formed on the first photoresist layer 241 with a first opening 242.

[0106] Next, refer to Image 6 According to the first opening 242, a groove 231 is formed on the substrate 21 by etching. The slot 231 is located on the first surface 211 of the substrate 21 and has a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com