Solar air heat absorber measurement and control system and performance and temperature prediction and protection method

A technology of measurement and control system and heat absorber, which is applied in the direction of solar thermal power generation, solar thermal device, machine/structural component testing, etc. It can solve the problems of poor air flow stability, poor reliability and durability, and no performance measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

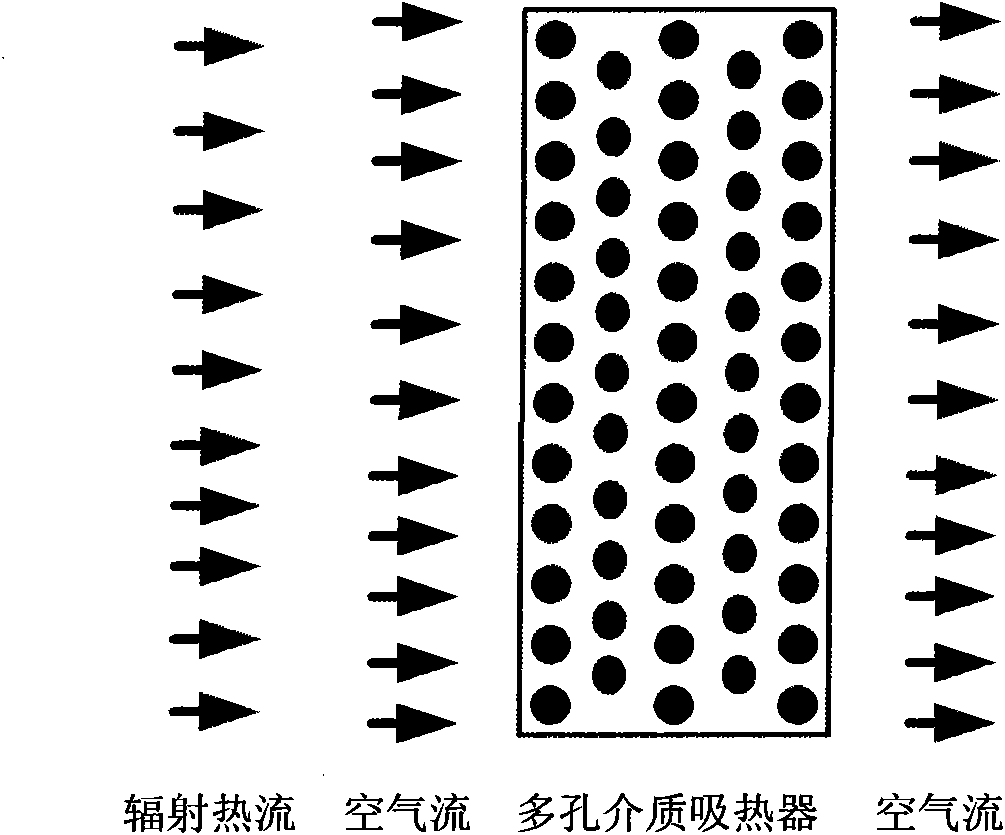

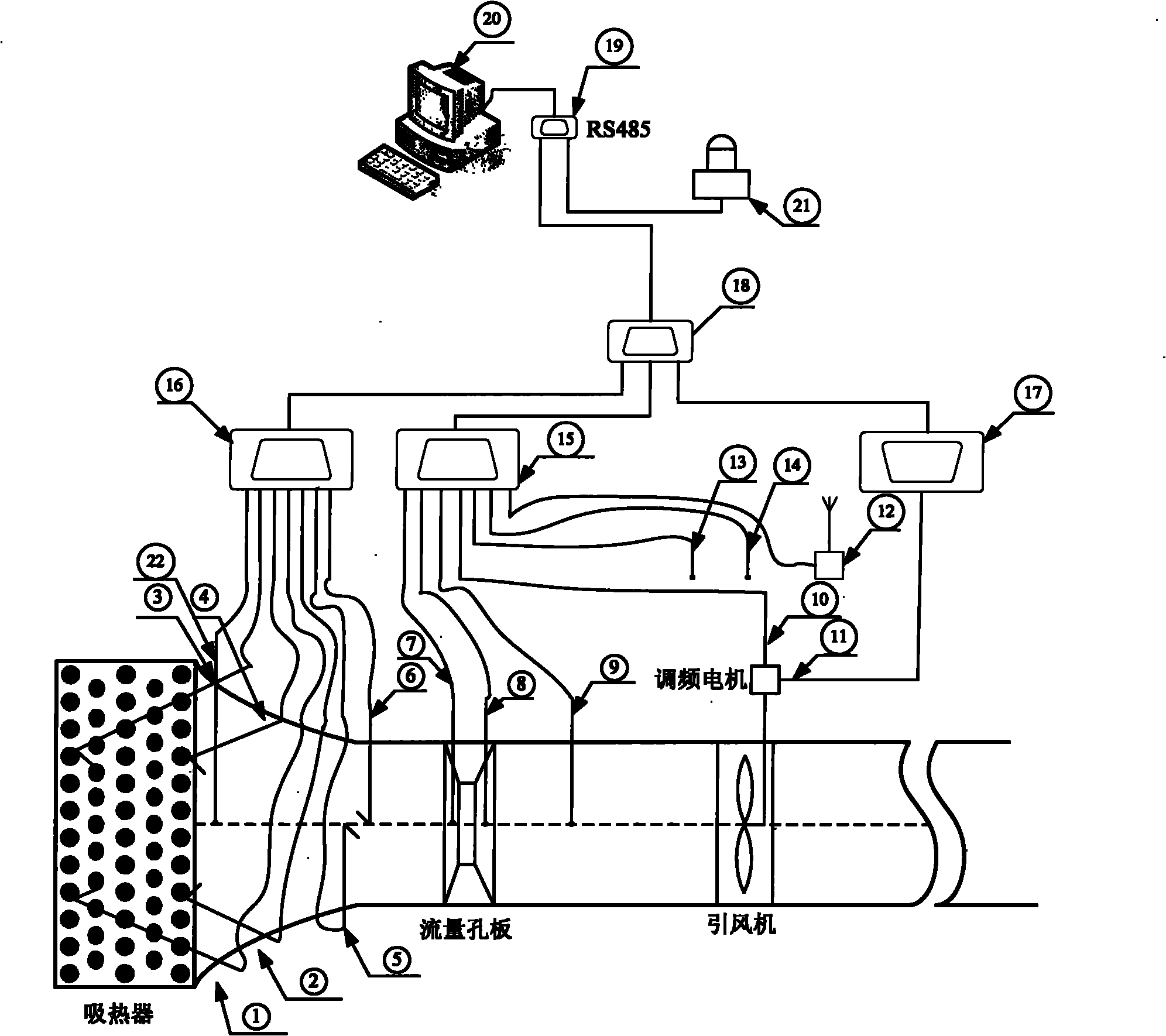

[0021] The working process of tower solar high temperature air silicon carbide ceramic heat sink is as follows: figure 1As shown, the heat-absorbing surface of the silicon carbide ceramic heat absorber receives the sun’s radiant energy, and transfers to the inside through the form of heat conduction in the solid skeleton, and when the air passes through the porous medium, it undergoes forced convection heat exchange with the porous medium, and the air is absorbed Heating, the temperature rises, and at the same time reduces the temperature of the solid skeleton of the porous medium, which protects the safety of the heat absorber. The resistance of the heat absorber is detected by the pressure sensors installed before and after the heat absorber; the efficiency of the heat absorber is calculated by measuring the direct solar radiation intensity, the efficiency of the heliostat and the air dissipation coefficient under quasi-steady state conditions. The input radiation energy of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com