Construction method for jointing of steel reinforcement cages of reinforced concrete drilling bored concrete pile

A technology for bored piles and reinforced concrete, which is applied to sheet pile walls, infrastructure engineering, construction, etc., can solve the problems of unguaranteed joint quality, slow construction speed, and complicated operation, and achieves good economic benefits and fast construction speed. , the effect of speeding up the docking speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

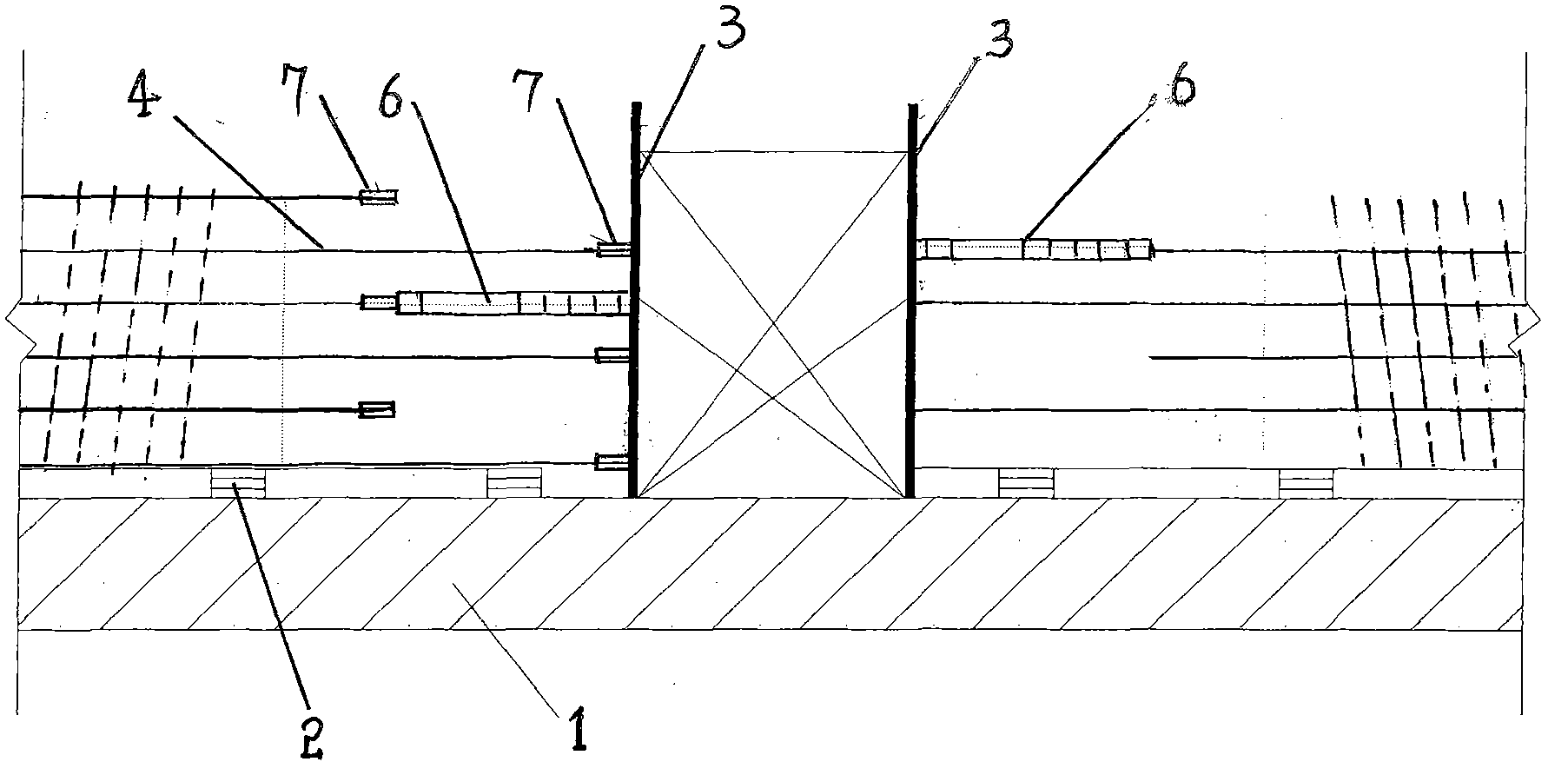

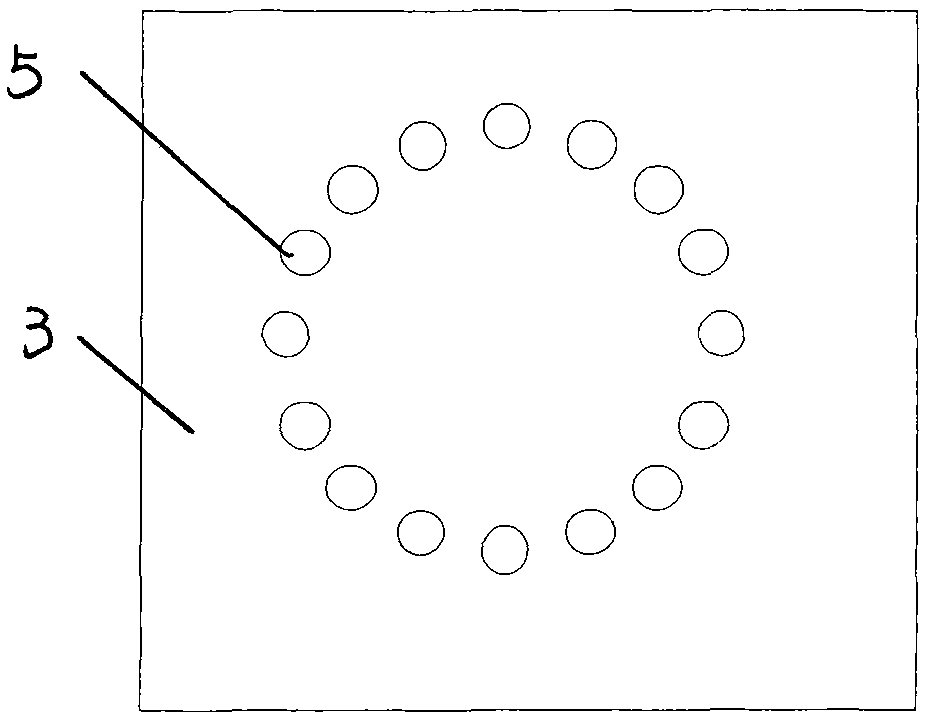

[0024] A reinforced concrete bored pile reinforcement cage butt joint construction method comprises the following steps:

[0025] 1) Rolling straight thread processing of steel bar end of steel cage

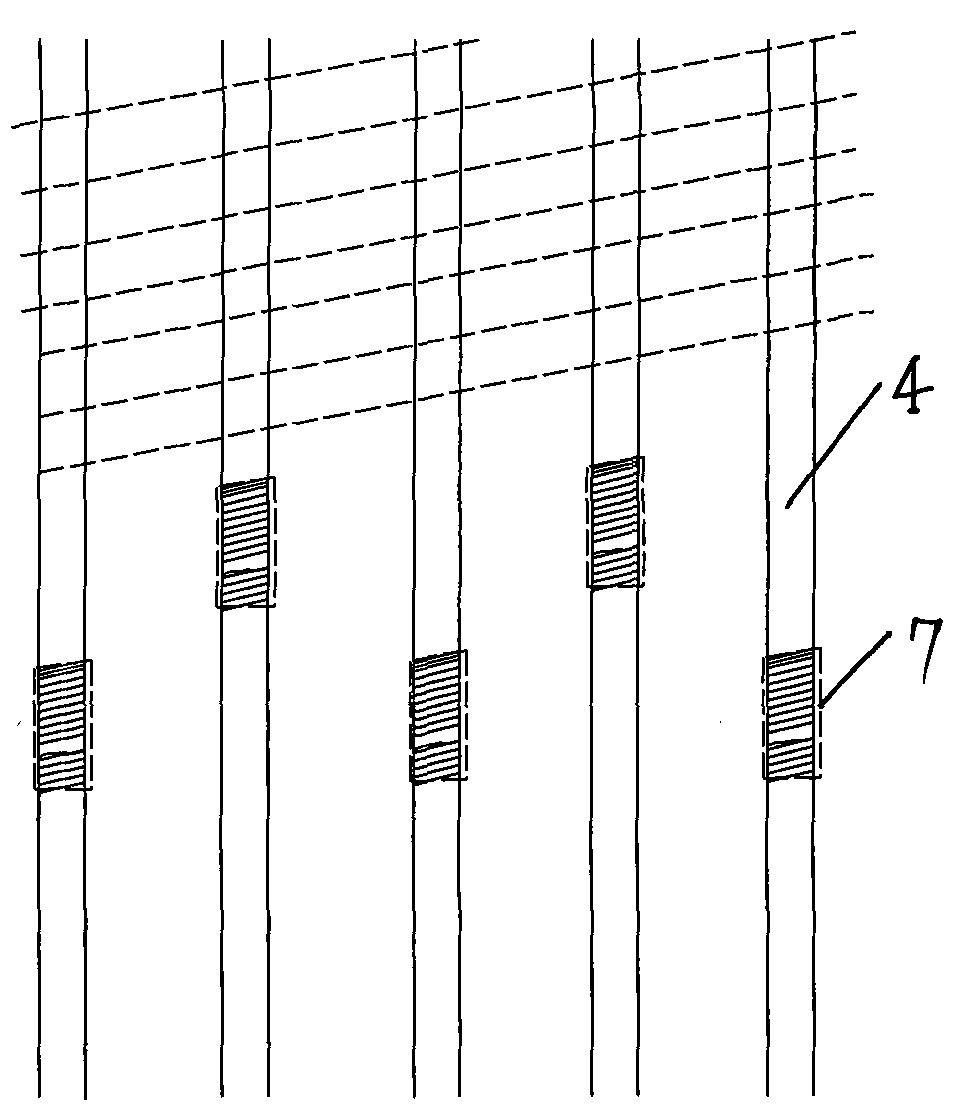

[0026] Grind the ends of the steel bars that need to be connected to be smooth, and then use a grinding wheel cutting machine or a grinding machine, and then process the rolling straight thread. The processing length and tooth angle of the straight thread are matched according to the selected straight thread sleeve. , where the end of the reinforcement cage needs to be docked, the processing length of the straight thread at the end of the reinforcement cage in the upper section is the length of the straight thread sleeve 7, and the processing length of the straight thread at the connection end of the reinforcement cage in the lower section is 1 / 2 straight thread Sleeve length, when processing straight threads, reserve 1 to 2 wires for the thread length; the main reinforcement of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com