Recombinant decorative material production waste water treatment process

A technology for the production of waste water and treatment process, which is applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can solve the problems of unstable operation effect, high operation cost, failure to meet discharge standards, etc. problems, to achieve low treatment costs, low operating costs, and reduce the effect of biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

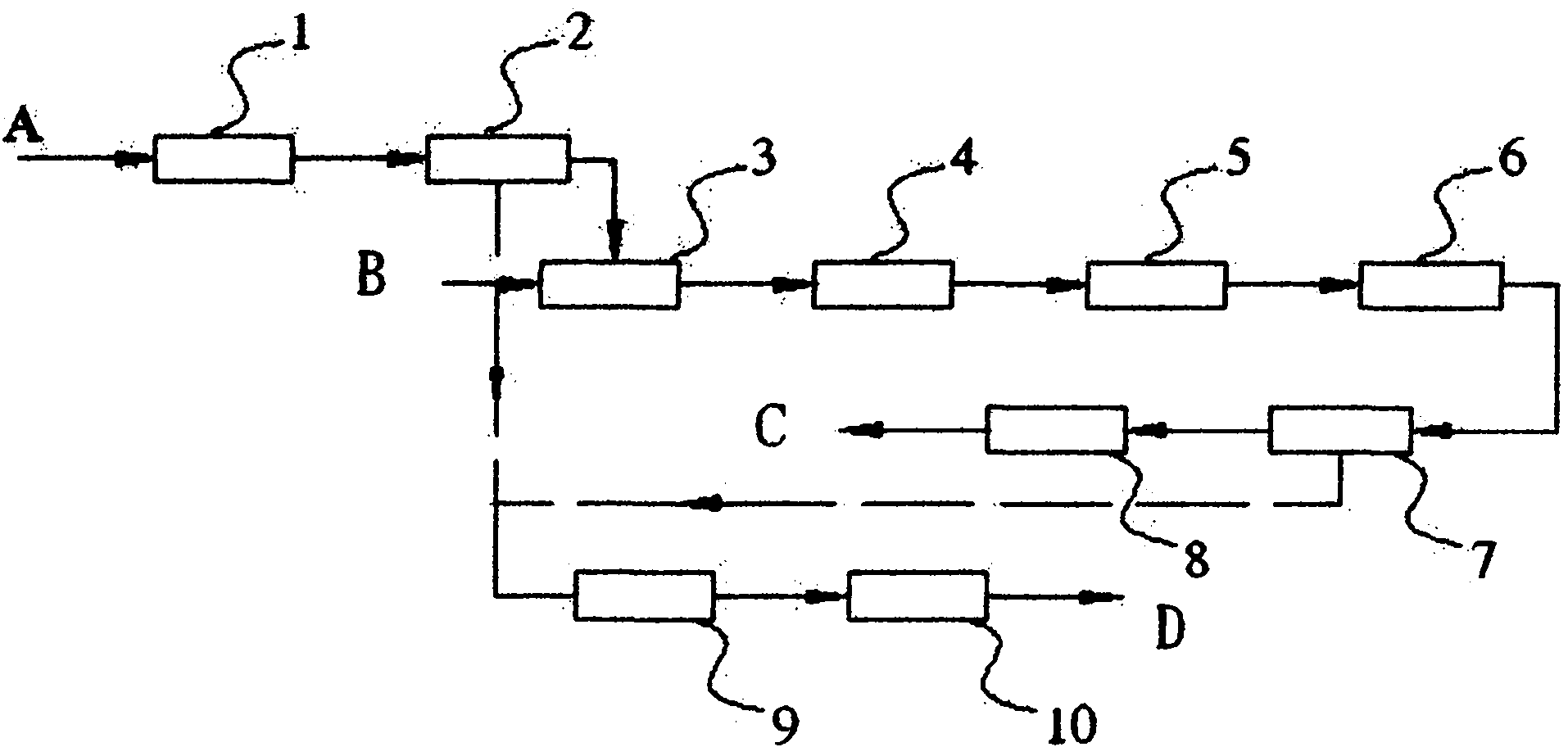

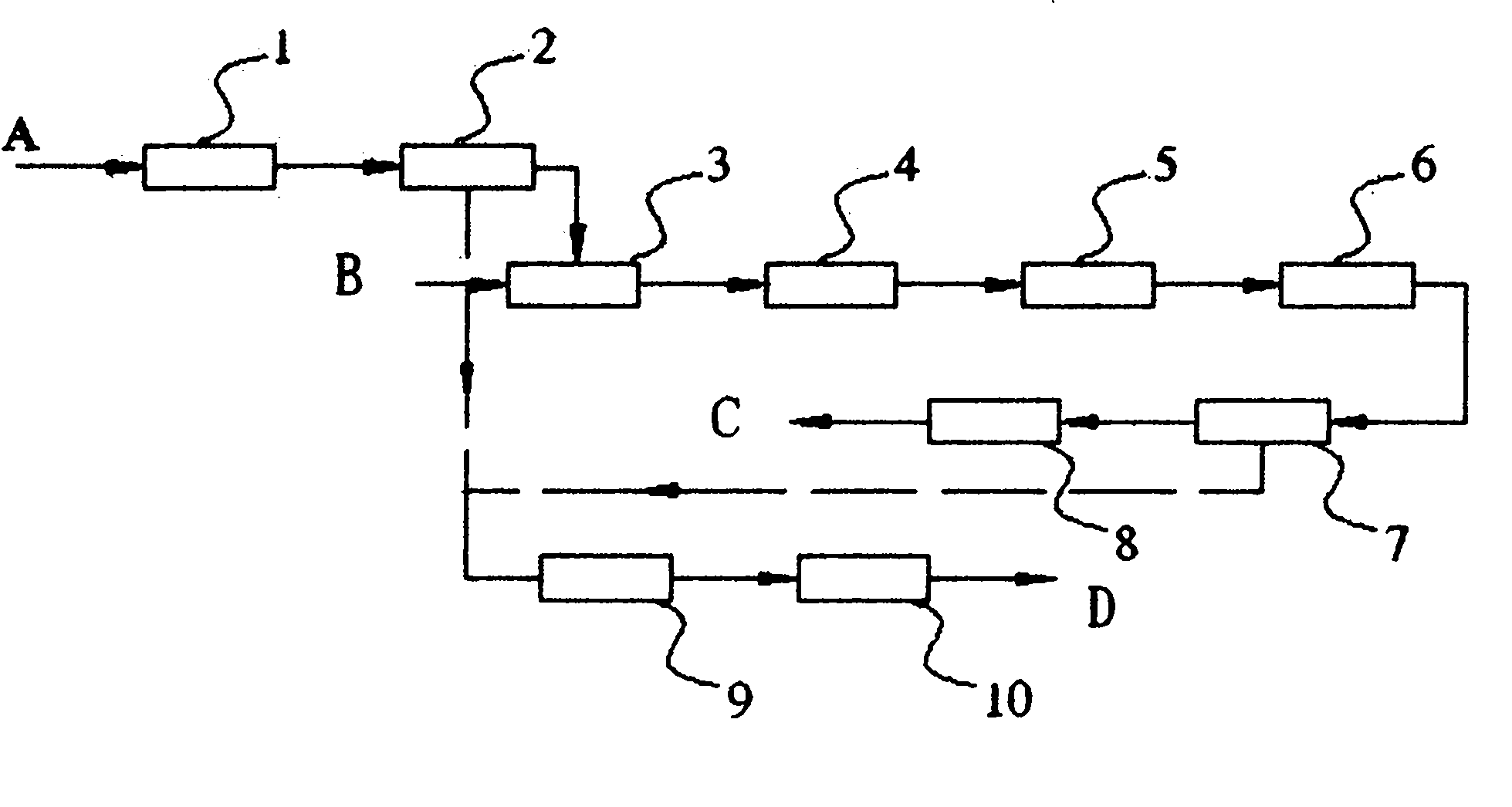

[0028] The invention has been applied to the water treatment project of a recombined decorative material production enterprise. figure 1 For the specific implementation of wastewater treatment process:

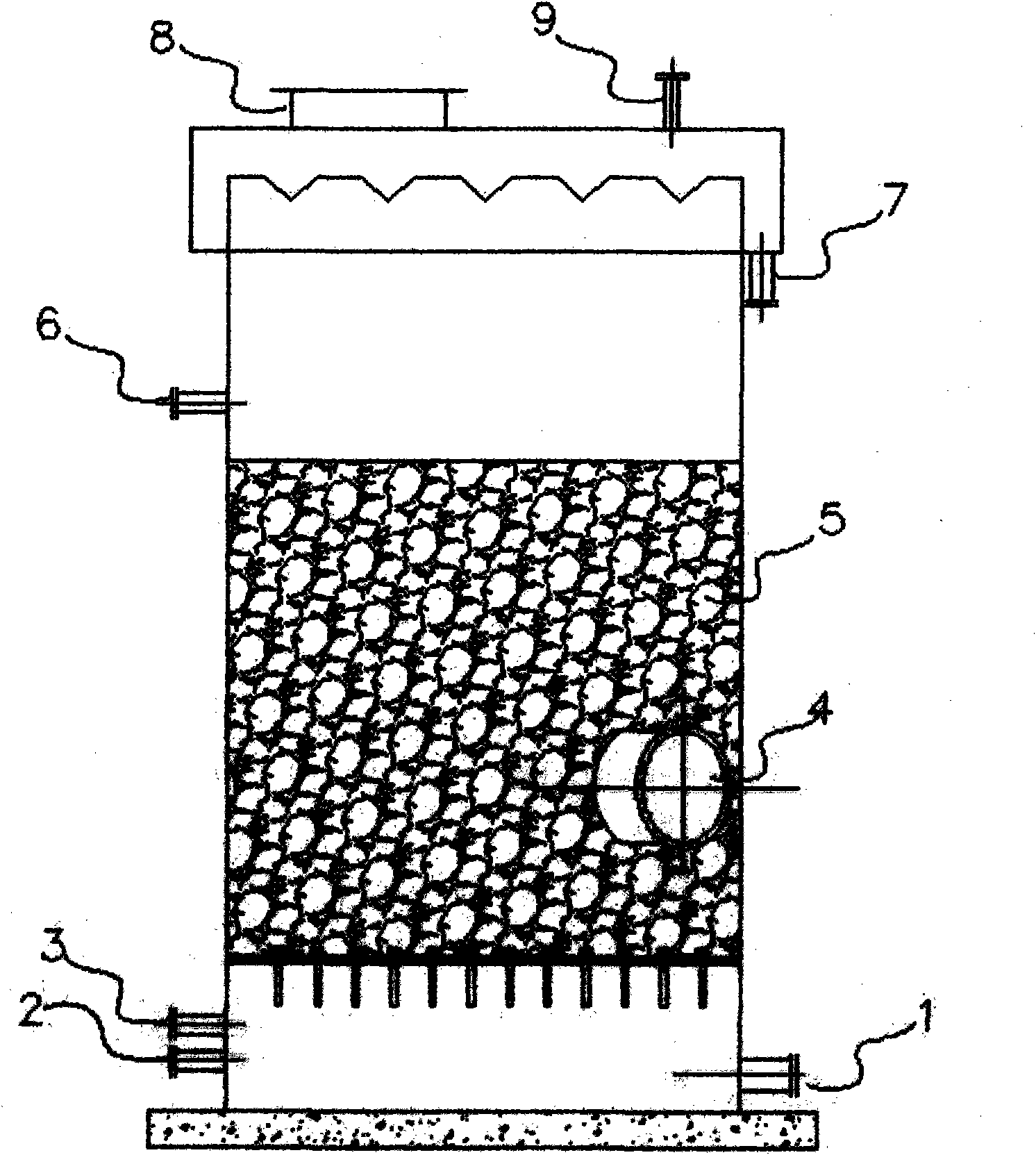

[0029] 1. The dyeing wastewater A with high COD and high chroma enters the iron-carbon tower 1 through the lift pump, and the wastewater undergoes micro-electrolysis reaction in the iron-carbon tower. Under weakly acidic conditions, the electrochemical reaction is carried out by utilizing the electrode potential difference between Fe and C. The chromophoric group of the dye is destroyed to remove the chromaticity, and part of the refractory organic matter is decomposed into easily degradable small molecule organic matter, improving the biodegradability of the wastewater. The best removal effect is achieved by controlling the residence time of wastewater and appropriate aeration; the continuous and stable operation of the iron carbon tower is ensured by proper backwashing and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com