Tea set special for Pu'er tea and manufacturing method thereof

A technology for Pu'er tea and tea set, applied in the field of special tea set for Pu'er tea and its preparation, can solve the problems of pollution, tea set pollution, insufficient anti-fouling property on the surface of tea set, etc., and achieve the effects of reducing environmental pollution, saving resources, and having a solemn and elegant shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

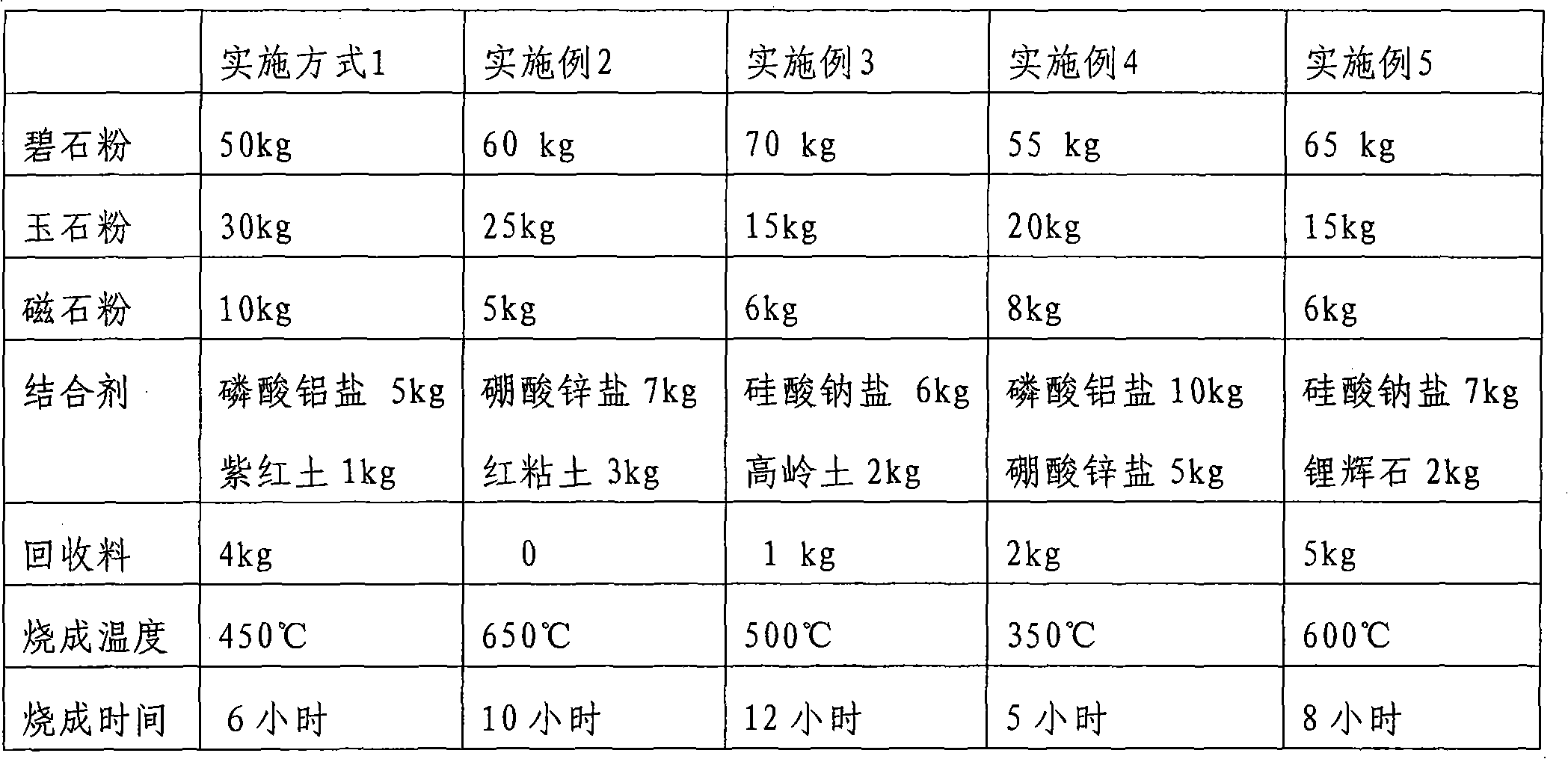

[0019] Bismuth powder, jade powder, magnetite powder, binder and recycled material powder were mixed and ground after adding water according to the proportions in Table 1, passed through a 325-mesh sieve, and the sieved material was taken as slurry, and the slurry was made into mud according to the prior art. After being molded by manual mud drawing, it is dried, and then fired at 450°C for 6 hours to become a tea set product. After firing, the tea set is naturally cooled and then decorated.

[0020] Among them, Tiebishi: 1250 mesh, from Xinjiang Altai Bishi Powder Factory; jade powder: annual powder and leftover waste produced by Ruili Jade Processing Factory in Yunnan, crushed to 325 mesh; Magnet: 325 mesh, Wenshan Maguan County The magnetite factory, the binder is aluminum phosphate, the vitrified binder product of Henan Abrasives and Abrasives Factory, adding purple clay is purple clay produced in Huaning County, and crushed to 325 mesh.

Embodiment approach 2

[0022] Iron-magnesite powder, jade powder, magnetite powder, and binder were mixed according to the proportions in Table 1 to prepare slurry for grouting. Other conditions are the same as in Example 1, the firing temperature is 650° C., and it is prepared by firing once for 10 hours.

[0023] Iron-magnesite: 1250 mesh, Bishi Mine in Ailaoshan Mountains, Yunnan; jade powder: powder and scraps from the jade processing plant in Lijiang, Yunnan, crushed to 325 mesh, magnet: 325 mesh. With embodiment 1, binding agent is self-made boric acid zinc salt, and it is composed of: potassium feldspar 35%, lepidolite 35%, borax 12, water glass 6, zinc oxide 4, add red clay to be Kunming red clay ore, mix Crush to 325 mesh.

Embodiment approach 3

[0025] Bishi powder, jade powder, magnetite powder, binder and recycled material powder were mixed according to the proportions in Table 1 and water was added to prepare slurry, dry granulated, pressed into billets, and then dried at 350°C for 12 hours once burnt.

[0026] The main materials are the same as those in Example 1, in which Tiebisite: 1250 mesh, comes from Bishi mine in Gaoligongshan Mountains, Yunnan, and the binder is sodium silicate salt, which is prepared by compound modification of powdered water glass and 15% titanium dioxide according to a conventional method, kaolin It is kaolin associated with coal measures in Huaning County, crushed to 325 mesh, and the rest are the same as in Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com