Raw material for making soybean milk and preparation method thereof

A preparation method and technology of raw materials, applied in the field of food, can solve the problems of thin soybean milk, long time consumption, affecting taste and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0081] Specific implementation steps:

[0082] (a) Raw material pretreatment (selection, drying, coarse grinding, passing through a 60-mesh sieve, superfine pulverization).

[0083] 1. Select high-quality soybeans with full grains, luster, no peculiar smell, no moths, no mildew, and no damage, and bake them at 125°C for 20 minutes.

[0084] 2. Coarse crushing.

[0085] 3. Pass the coarsely crushed beans through a 60-mesh sieve.

[0086] 4. The sieved soybean powder is pulverized for the second time with an ultrafine pulverizer.

[0087] 5. Collect the ultrafinely pulverized soybean flour and use it as raw material powder for subsequent use.

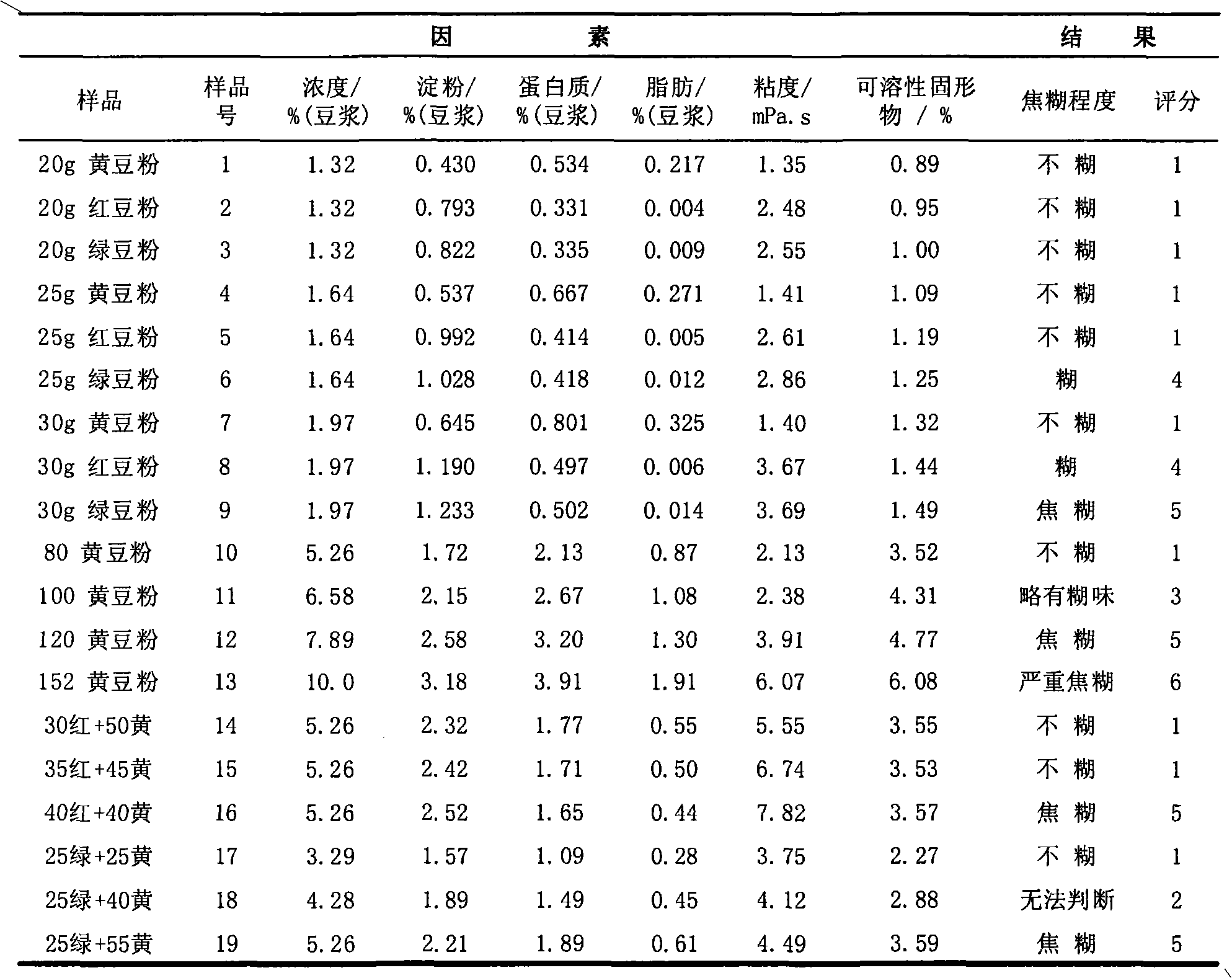

[0088] (b) Add 80g, 100g, 120g, and 152g of soybean powder into the soymilk maker, add water to the mark (the total weight of solid and liquid is 1520g), and stir evenly to make pulp. The measurement indicators are: soybean milk concentration, starch content, protein content, fat content, viscosity, soluble matter content, burnt degre...

example 2

[0094] Specific implementation steps:

[0095] (a) Raw material pretreatment (selection, drying, coarse grinding, passing through a 60-mesh sieve, superfine pulverization).

[0096] 1. Select high-quality soybeans, red beans, and mung beans with full grains, luster, no peculiar smell, no moths, no mildew, and no damage, and bake them at 125°C for 20 minutes.

[0097] 2. Coarse crushing.

[0098] 3. Pass the coarsely crushed beans through a 60-mesh sieve.

[0099] 4. The sieved soybean powder is pulverized for the second time with an ultrafine pulverizer.

[0100] 5. Collect the ultrafinely pulverized soybean flour and use it as raw material powder for subsequent use.

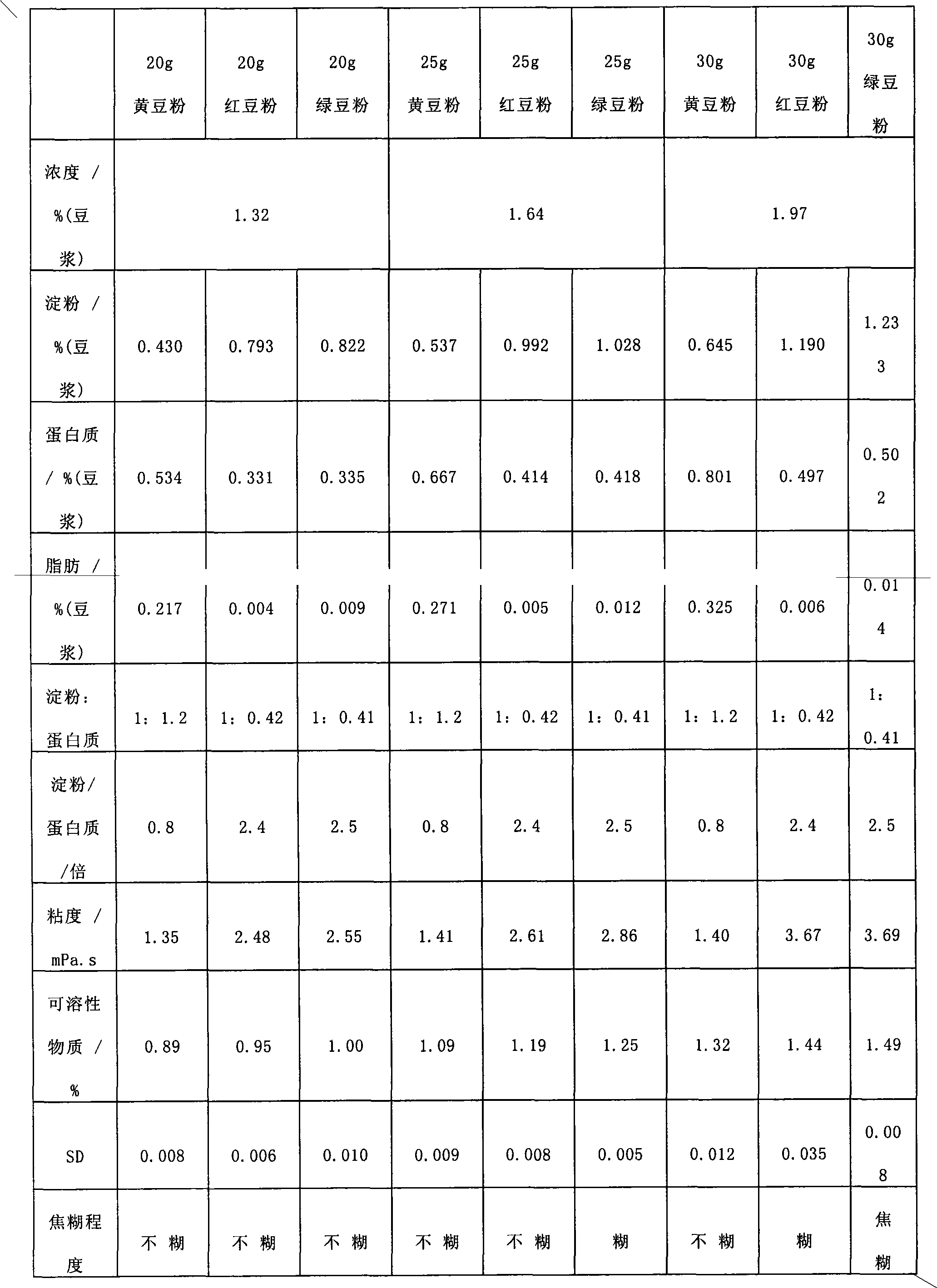

[0101] (b) Add 20g, 25g and 30g of soybean powder, red bean powder and mung bean powder respectively into the soymilk machine, add water to the scale line (the total weight of solid and liquid is 1520g) and stir evenly to make pulp. The measurement indicators are: soybean milk concentration, starch content, ...

example 3

[0107] Specific implementation steps:

[0108] (a) Raw material pretreatment (selection, drying, coarse grinding, passing through a 60-mesh sieve, superfine pulverization).

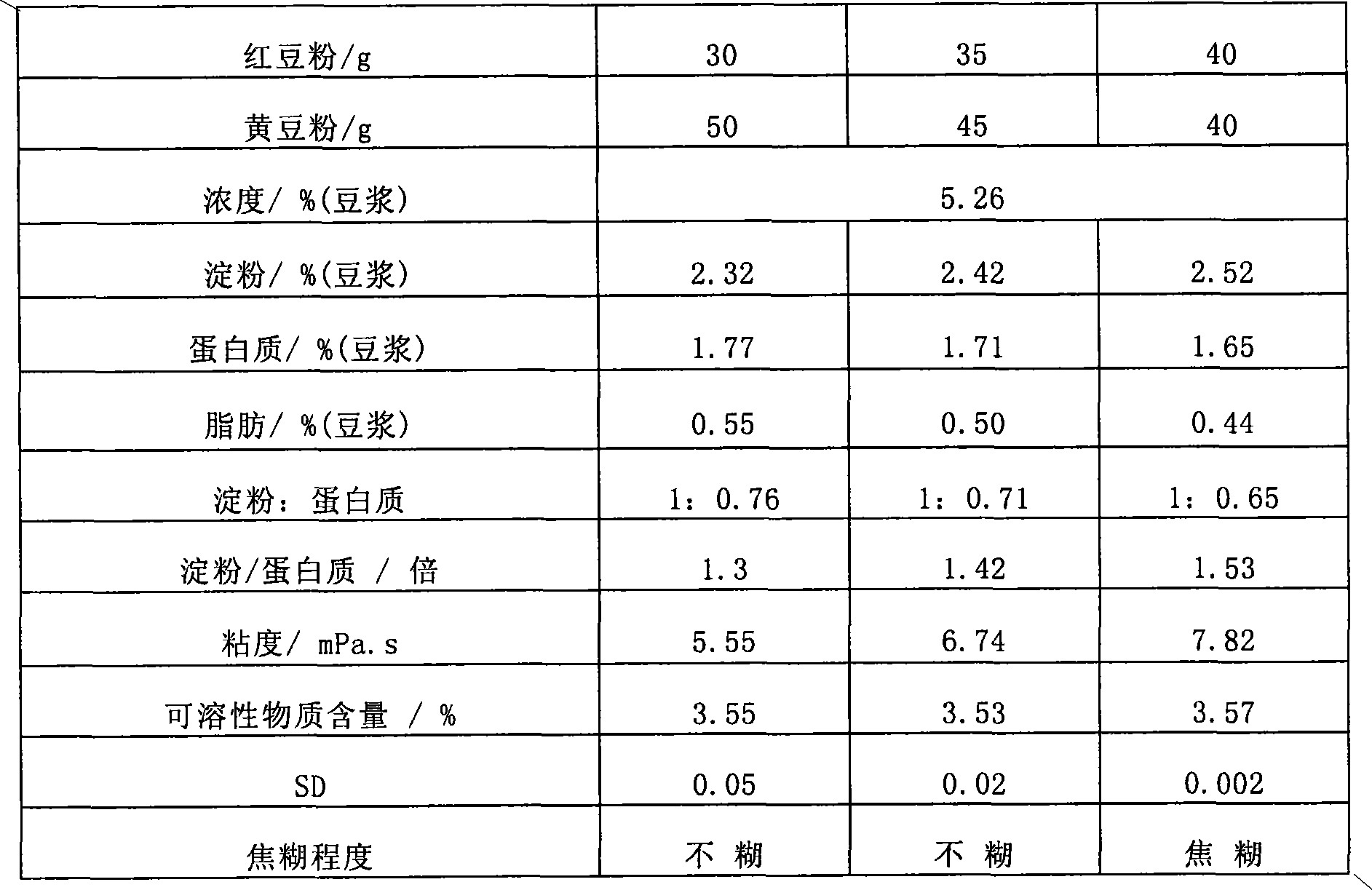

[0109] (b) Soybean powder and red bean powder are compounded (①30g red bean powder+50g soybean powder; ②35g red bean powder+45g soybean powder; ③40g red bean powder+40g soybean powder). Put the compound soybean powder in a soymilk machine, add water to the mark (the total weight of solid and liquid is 1520g) and stir evenly to make pulp. The measurement indicators are: soybean milk concentration, starch content, protein content, fat content, viscosity, soluble matter content, burnt degree.

[0110] (c) Soybean flour and mung bean flour are compounded (①25g mung bean flour+25g soy flour;②25g mung bean flour+40g soy flour;③25g mung bean flour+55g soy flour). Put the compound soybean powder in a soymilk machine, add water to the mark (the total weight of solid and liquid is 1520g) and stir evenly to make p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com