Re-condensation reclaiming system for evaporated gas of liquefied natural gas receiving station and reclaiming method thereof

A technology for liquefied natural gas and boil-off gas, which is applied to the boil-off gas re-condensation recovery system and its recovery field of LNG receiving station, can solve the problems of BOG not being completely absorbed or condensed, energy waste, difficult operation, etc. Stable condition, improved operation stability, good effect of fluctuation adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

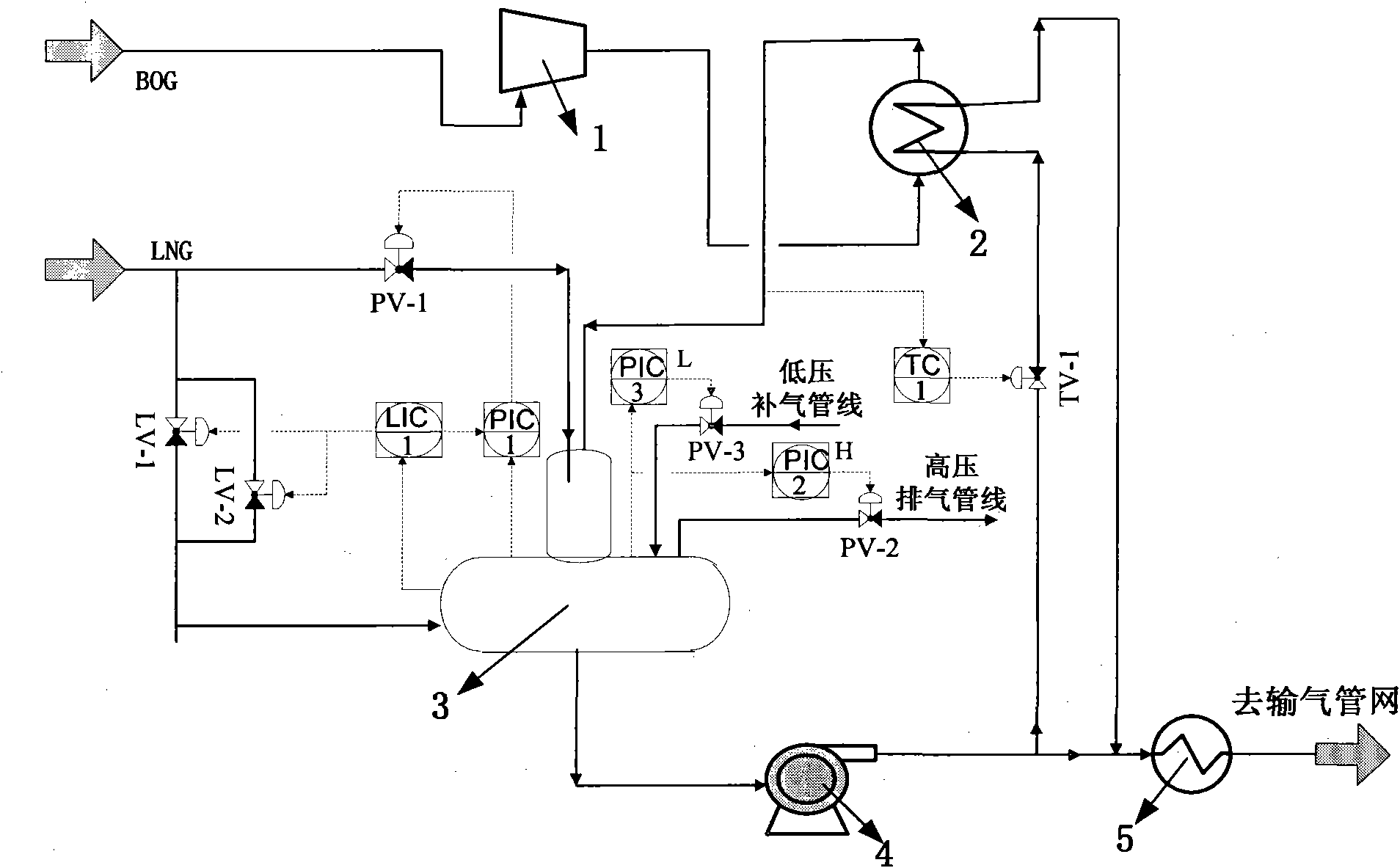

[0051] A recondensation recovery system for boil-off gas at a liquefied natural gas receiving station: the system includes a boil-off gas compressor ( Figure 3-1 ), evaporating gas precooling heat exchanger ( Figure 3-2 ), recondenser ( Figure 3-3 ), pressure controller (including PIC-1, PIC-2 and PIC-3) and liquid level controller LIC-1; the evaporated gas compressor, evaporated gas precooling heat exchanger and recondenser are connected in sequence, and the pressure The controller and the liquid level controller are respectively connected with the recondenser; the recondenser consists of a vertical condensation tower ( Pic 4-1 ) and high pressure pump buffer tank ( Figure 4-2 ), the vertical condensing tower is located above the buffer tank of the high-pressure pump.

[0052] The top of the vertical condensing tower is provided with a low-pressure liquefied natural gas I inlet ( Figure 4-4 ) and boil-off gas inlet ( Figure 4 -6), the vertical condensing tower is ...

Embodiment 2

[0055] A receiving station receives imported LNG by ship, and its molar composition is as follows: methane 88.774%, ethane 7.542%, propane 2.588%, isobutane 0.454%, n-butane 0.562%, isopentane 0.004%, nitrogen 0.074%. LNG storage tanks are two stocks of 1.6 x 10 5 m 3 The full-capacity concrete low-temperature atmospheric pressure storage tank, the operating pressure is 0.15Kg / cm 2 G, the LNG storage capacity of the two storage tanks is 147520t. The daily evaporation of LNG is less than 0.05% (mass fraction), under normal operating conditions, about 6.7t of BOG gas is produced per hour, the LNG output is 180t / h, and the pressure of the gas pipeline network is 95kg / cm 2g. Embodiment Using the BOG pre-cooling process designed by the present invention and the BOG recondensation recovery method with the high-pressure pump buffer tank, the cold capacity carried by LNG is used to pre-cool the compressed BOG gas, and the cold source comes from the low-temperature sent to the vapor...

Embodiment 3

[0067] A receiving station receives imported LNG by ship, and its molar composition is as follows: 96.6% methane, 1.97% ethane, 0.4% propane, 0.07% isobutane, 0.07% n-butane, and 0.89% nitrogen. There are 3 LNG storage tanks with a volume of 1.3×10 5 m 3 The underground storage tank, the operating pressure is 0.19Kg / cm 2 G, the total LNG reserves of the 3 storage tanks are 169950t. According to statistics, the daily evaporation of LNG is about 0.1% (mass fraction), under normal operating conditions, about 8.5t of BOG gas is produced per hour, the LNG output is 200t / h, and the pressure of the gas pipeline network is 78kg / cm 2 g. Embodiment Using the BOG pre-cooling process designed by the present invention and the BOG recondensation recovery method with the high-pressure pump buffer tank, the cold capacity carried by LNG is used to pre-cool the compressed BOG gas, and the cold source comes from the low-temperature sent to the vaporizer in the system High pressure LNG.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com