Cement-stabilizing broken stone used for highway subgrade

A cement-stabilized crushed stone and cement technology, applied in roads, roads, buildings, etc., can solve the problem of inability to ensure accurate metering and uniform mixing of admixtures, and the duration is generally about 2 to 3 hours, sometimes even 4 to 5 hours, etc. problems, achieve significant economic and social benefits, and reduce environmental load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A cement-stabilized crushed stone for highway subgrade using waste slag, which is composed of 4.0% by weight of clinker-free steel slag cement with a strength grade of 32.5, 30% by weight of recycled aggregate, 70% by weight of natural aggregate, and the balance of water, stirring and mixing made. The processing steps are as follows: first add the required amount of aggregate and mix, then add clinker-free steel slag cement in the form of external addition, and finally add water and mix together. The aggregate gradation and dosage used are shown in Table 1.

[0021] Table 1 Aggregate grading and dosage

[0022] aggregate grading

[0023] Using recycled 30% by weight aggregate, it is used to replace part of the amount of natural aggregate of the same particle size.

Embodiment 2

[0025] A cement-stabilized crushed stone for highway subgrade using waste slag, which is composed of 4.5% by weight of clinker-free steel slag cement with a strength grade of 32.5, 30% by weight of recycled aggregate, 70% by weight of natural aggregate, and the balance of water, stirring and mixing made.

Embodiment 3

[0027] A cement-stabilized crushed stone for highway subgrade using waste slag, which is composed of 5.0% by weight of clinker-free steel slag cement with a strength grade of 32.5, 30% by weight of recycled aggregate, 70% by weight of natural aggregate, and the balance of water, stirring and mixing made.

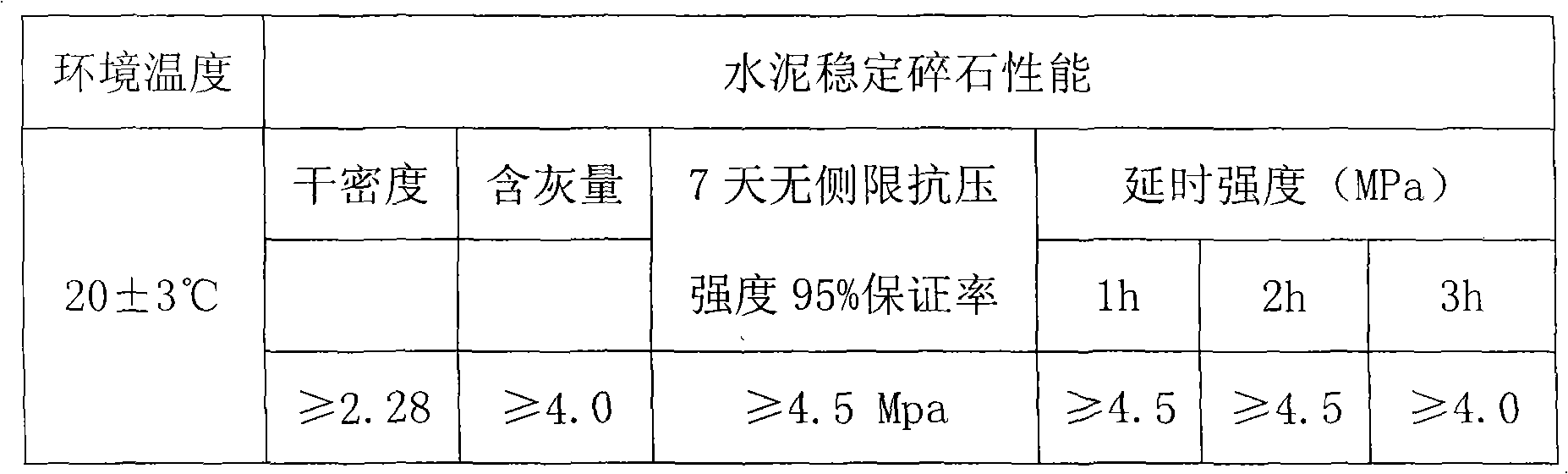

[0028] Under ambient temperature conditions, the dry density, ash content and strength requirements of the final prepared cement-stabilized macadam for highway subgrades shall be controlled according to the following table:

[0029]

[0030] By adjusting the different dosages and proportions of these two materials and natural gravel, the 7-day unconfined compressive strength of cement-stabilized gravel for highway subgrades can actually reach more than 4.5Mpa, which can meet the requirements of high-grade highways and is suitable for Used in the construction of urban roads.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com