Ink composition for ink jet recording

A technology of inkjet recording and composition, applied in the field of ink composition for inkjet recording, capable of solving the problems of insufficient ink ejection stability or blockage recovery, insufficient ink storage stability, and desorption, etc. Achieves excellent color rendering or fixability, excellent ejection stability or clogging recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

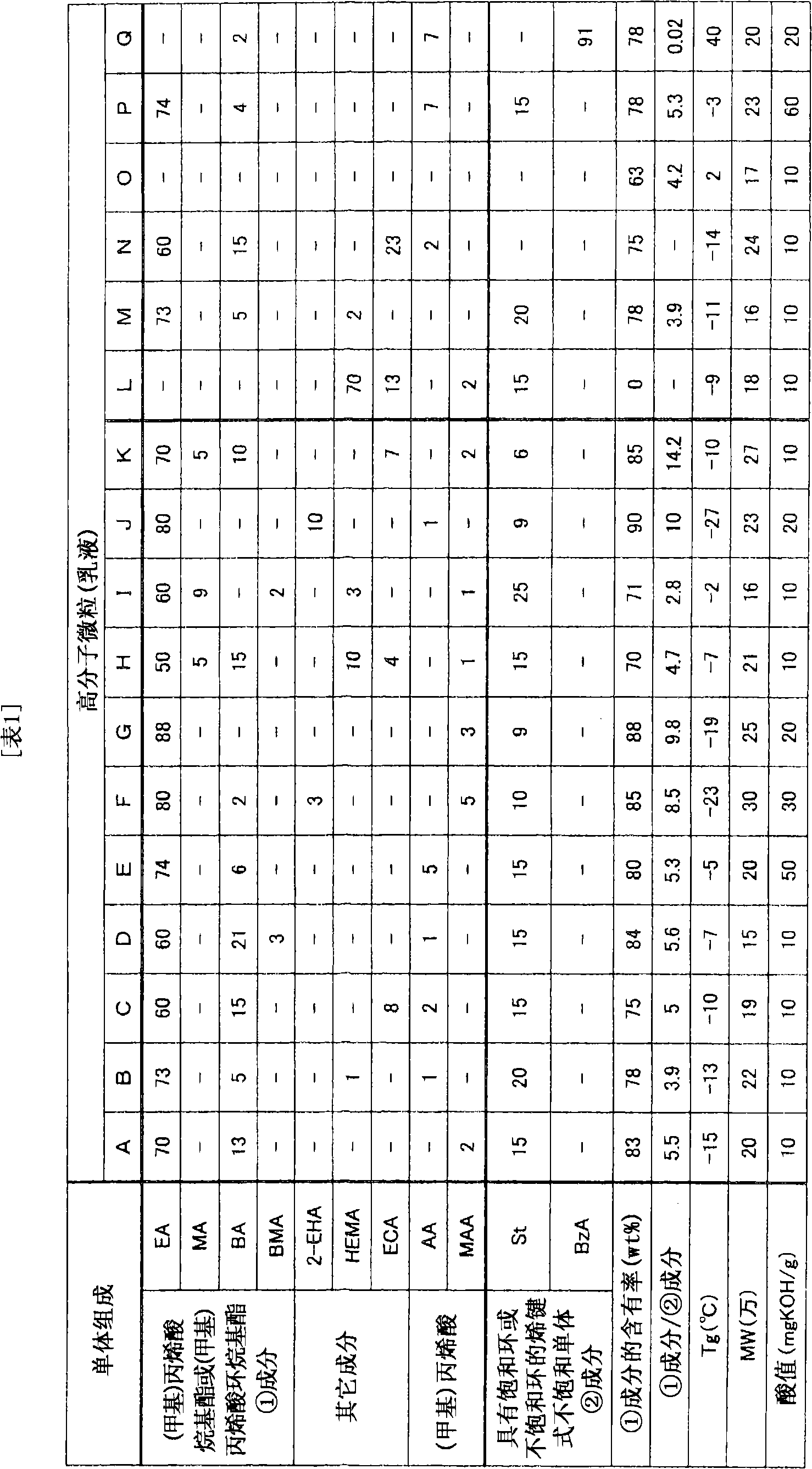

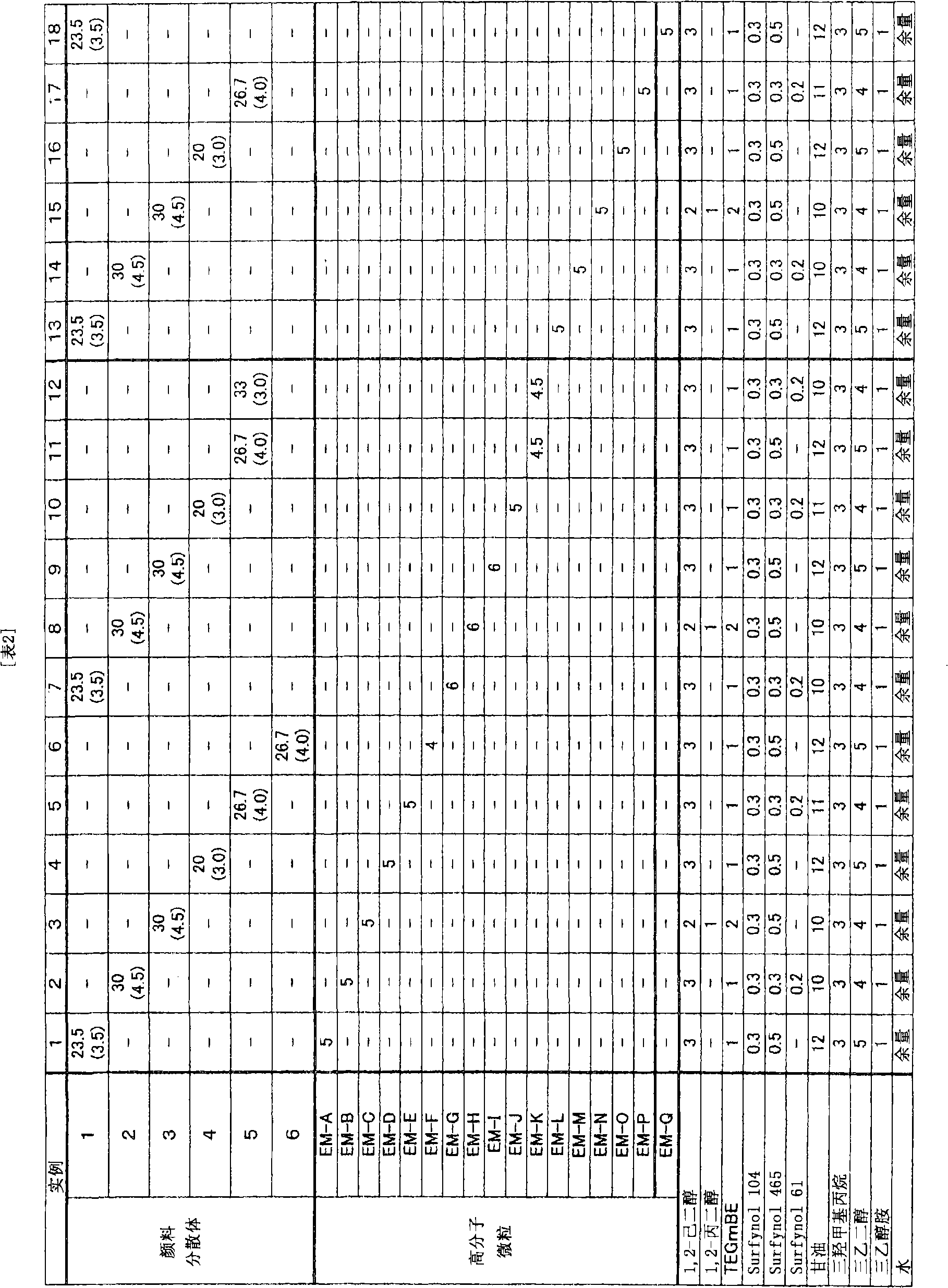

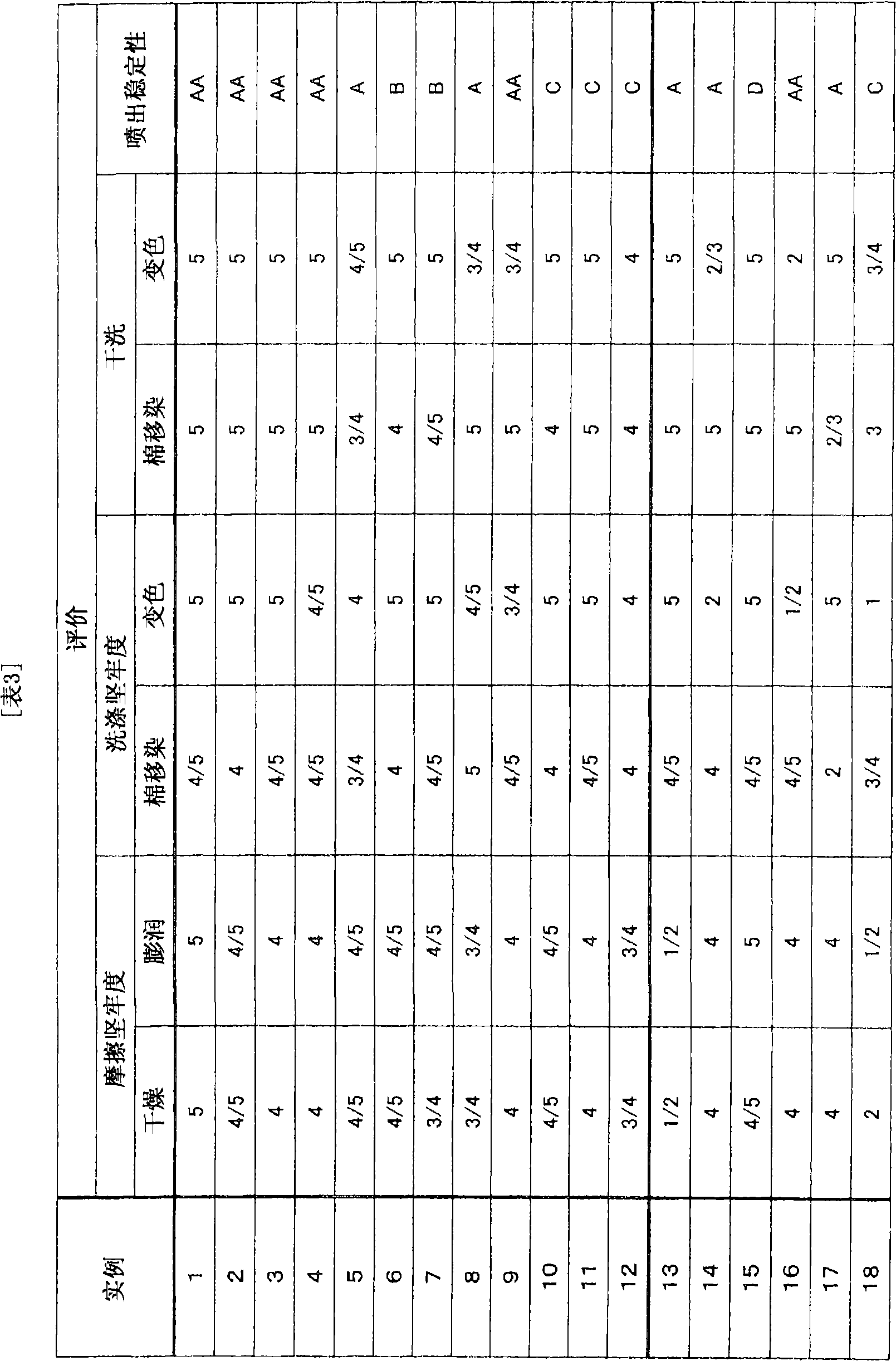

[0068] Hereinafter, the present invention will be described in further detail using examples, but the present invention is not limited by these examples.

[0069]

[0070] Emulsion A

[0071] In the reaction vessel equipped with dropping device, thermometer, water-cooled co-current condenser, and stirrer, add 100 parts of ion-exchanged water, add 0.2 parts of polymerization initiator potassium persulfate at 70°C under nitrogen atmosphere while stirring, and Add 0.05 parts of sodium lauryl sulfate, 30 parts of ethyl acrylate, 8 parts of butyl acrylate, 5 parts of styrene and 0.02 parts of tert-dodecyl mercaptan into 7 parts of ion-exchanged water dropwise at 70 ° C. The solution was reacted to produce Class 1 material. Add 2 parts of ammonium persulfate 10% solution to the first-grade material and stir, and then add 30 parts of ion-exchanged water, 0.2 parts of potassium lauryl sulfate, 40 parts of ethyl acrylate, and 5 parts of butyl acrylate while stirring at 70°C. ester...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com