Tape package of chip components and preparation method and device thereof

A technology for preparing devices and components, which is applied in the directions of packaging, transportation and packaging, and sending objects, and can solve the problems of unable to tear the tape normally, high bonding force between the tape and the carrier tape, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

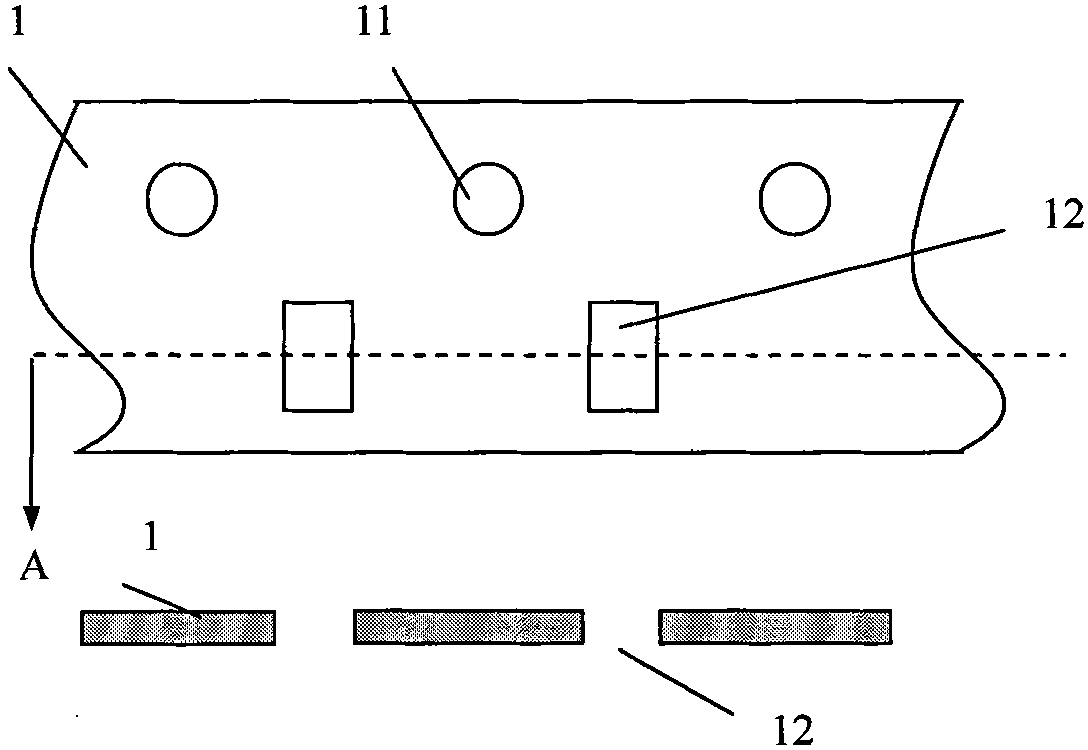

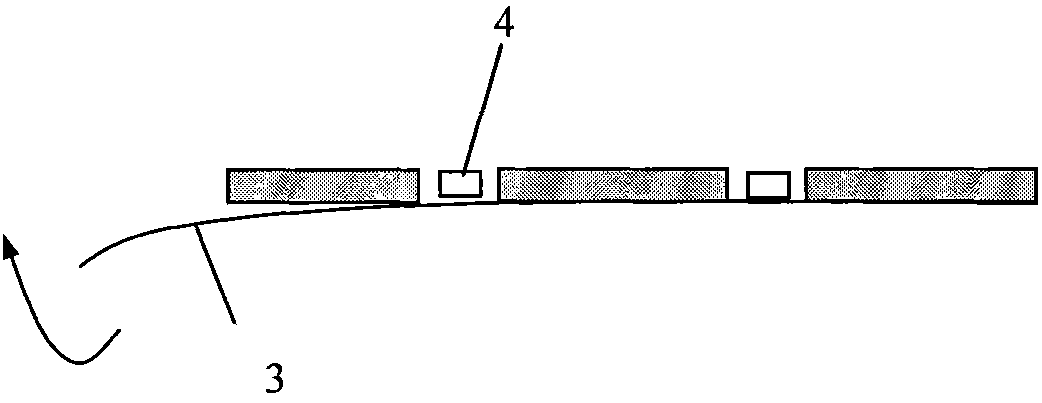

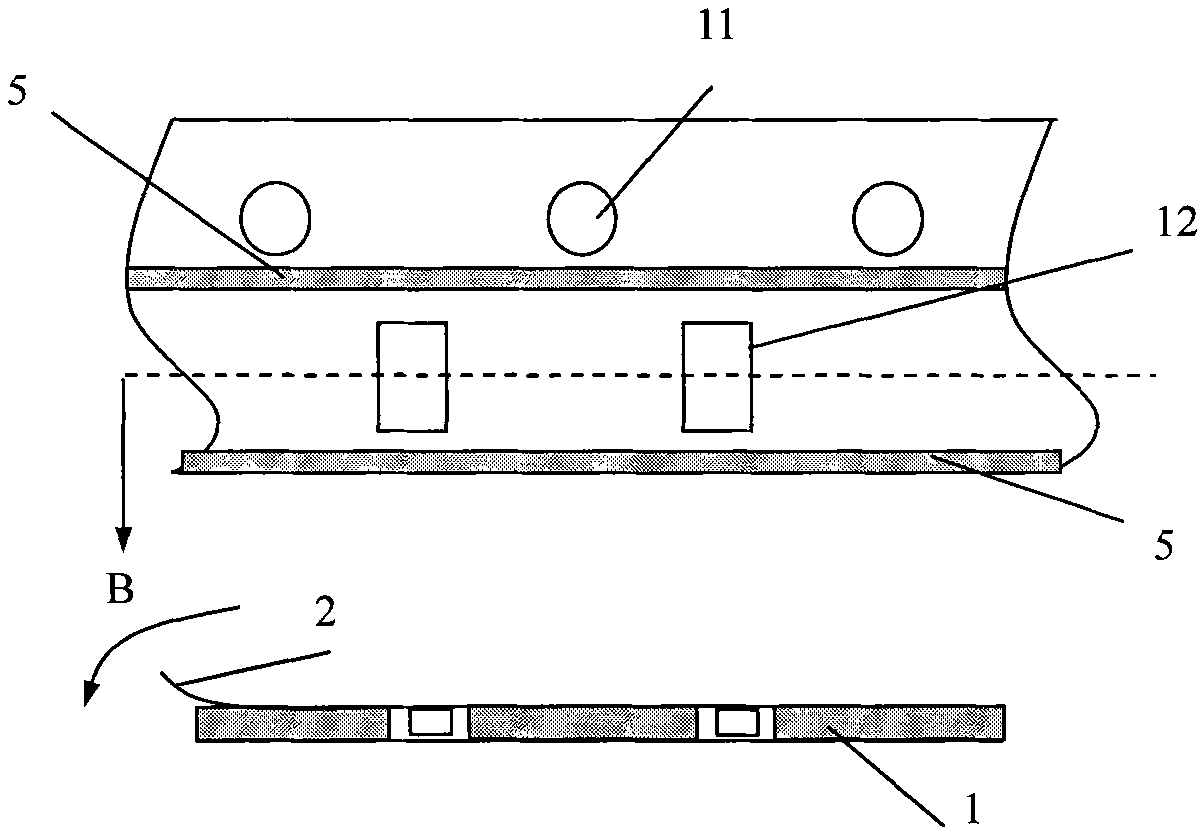

[0029] The preparation method of the braided packaging of the above-mentioned chip components includes the following steps: first, put the chip components 4 into the square hole 12 of the back-sealed carrier tape 1; then seal the upper surface of the carrier tape 1 with an adhesive tape 2 , and two easy-tear lines 6 parallel to the joint site 5 are set on the inner side of the joint site 5 . The easy-to-tear line 6 is formed by scraping, punching or laser technology.

[0030] Or, the preparation method of the braided packaging of the above-mentioned chip components includes the following steps: first, put the chip components 4 into the square hole 12 of the back-sealed carrier tape 1; The adhesive tape 2 of the tearing line 6 seals the upper surface of the carrier tape 1 , and the two parallel easy-tearing lines 6 are located at the inner side of the bonding portion 5 of the adhesive tape 2 and the carrier tape 1 after sealing.

Embodiment 1

[0033] like Figure 5 As shown, the cross section of the heating block 7' of the original tape braiding machine is designed to be concave, and the protrusions on the left and right sides are heating contact surfaces, which are used to heat the tape, so that the tape 2 and the carrier tape 1 are fused to form two parallel heating Traces, i.e. binding sites5.

[0034] This embodiment improves the braiding machine heating block on the original basis, as Image 6 As shown, two slightly protruding scrapers 71 are added on the inner side of the heating contact surface of the heating block 7, and the scrapers are required to be too high so as not to completely cut off the adhesive tape. In this way, when the heating block 7 is in use, the adhesive tape 2 and the carrier tape 1 move under the heating block 7, and the heating block 7 forms two thin lines at the inside of the joint 5 while forming two heating traces to bond the adhesive tape and the carrier tape. Groove, i.e. easy tea...

Embodiment 2

[0036] like Figure 5 As shown, the cross section of the heating block 7' of the original tape braiding machine is designed to be concave, and the protrusions on the left and right sides are heating contact surfaces, which are used to heat the tape, so that the tape 2 and the carrier tape 1 are fused to form two parallel heating Traces, i.e. binding sites5.

[0037] like Figure 7 As shown, in this embodiment, on the basis of the original equipment, a pair of pin wheels 8 or dotted line cutting hobs are installed behind the original heating block 7', and the heating contact surface between the pin wheels 8 or dotted line cutting hobs and the heating block Parallel inside. Like this, when adhesive tape 2 moves below heating block 7 ' and pin wheel 8, will pull pin wheel 8 to rotate. Pin wheel 8 will pierce a large amount of thin pinholes on the adhesive tape in the process of rotation, and these thin pinholes are connected into two rows of parallel dotted lines.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com