Apparatus for introducing sheet into sheet-fed printing press

A technology for introducing devices and sheets, which can be used in printing presses, general parts of printing machinery, printing devices, etc., and can solve the problems of high production cost, complex structure and control of supporting elements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

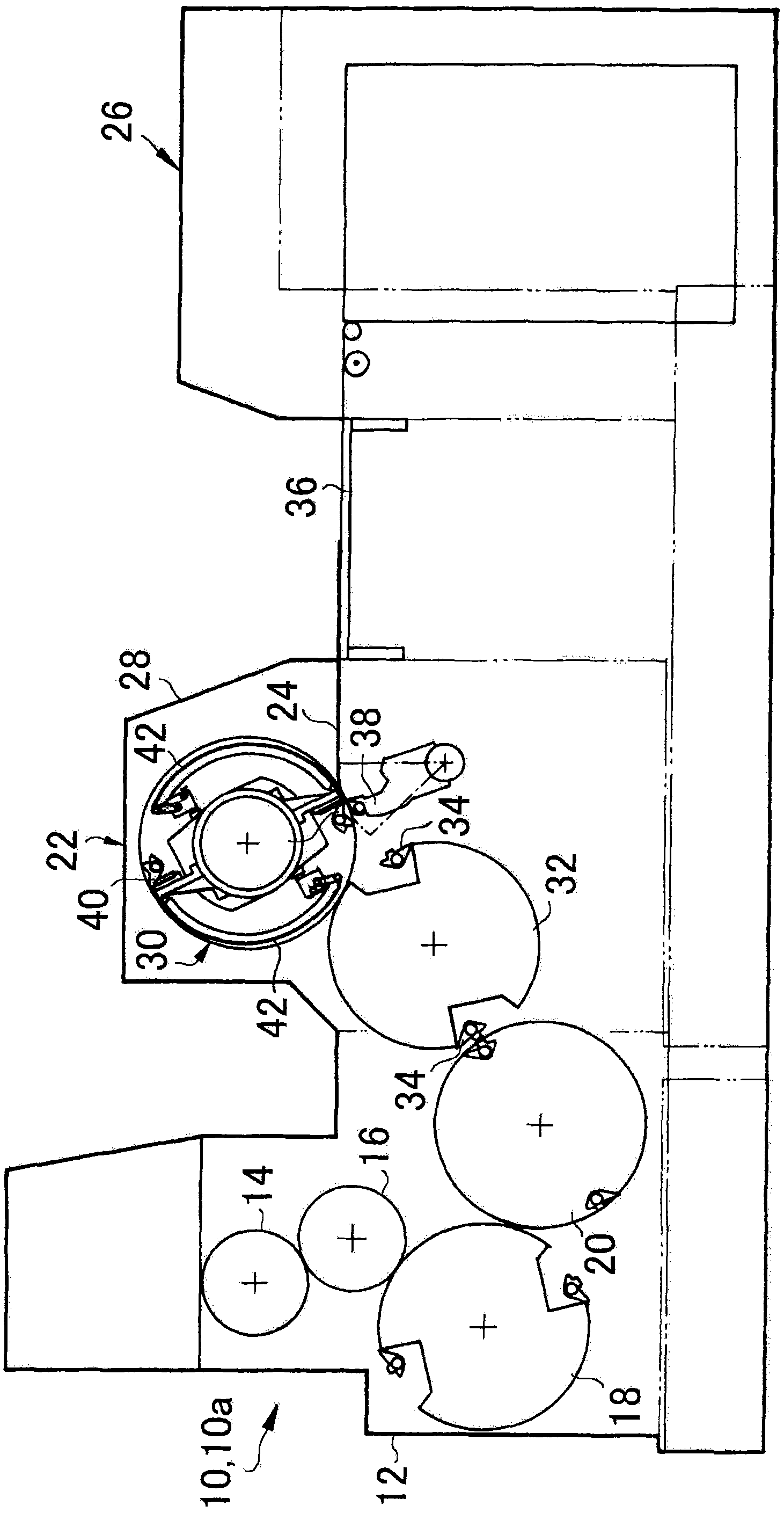

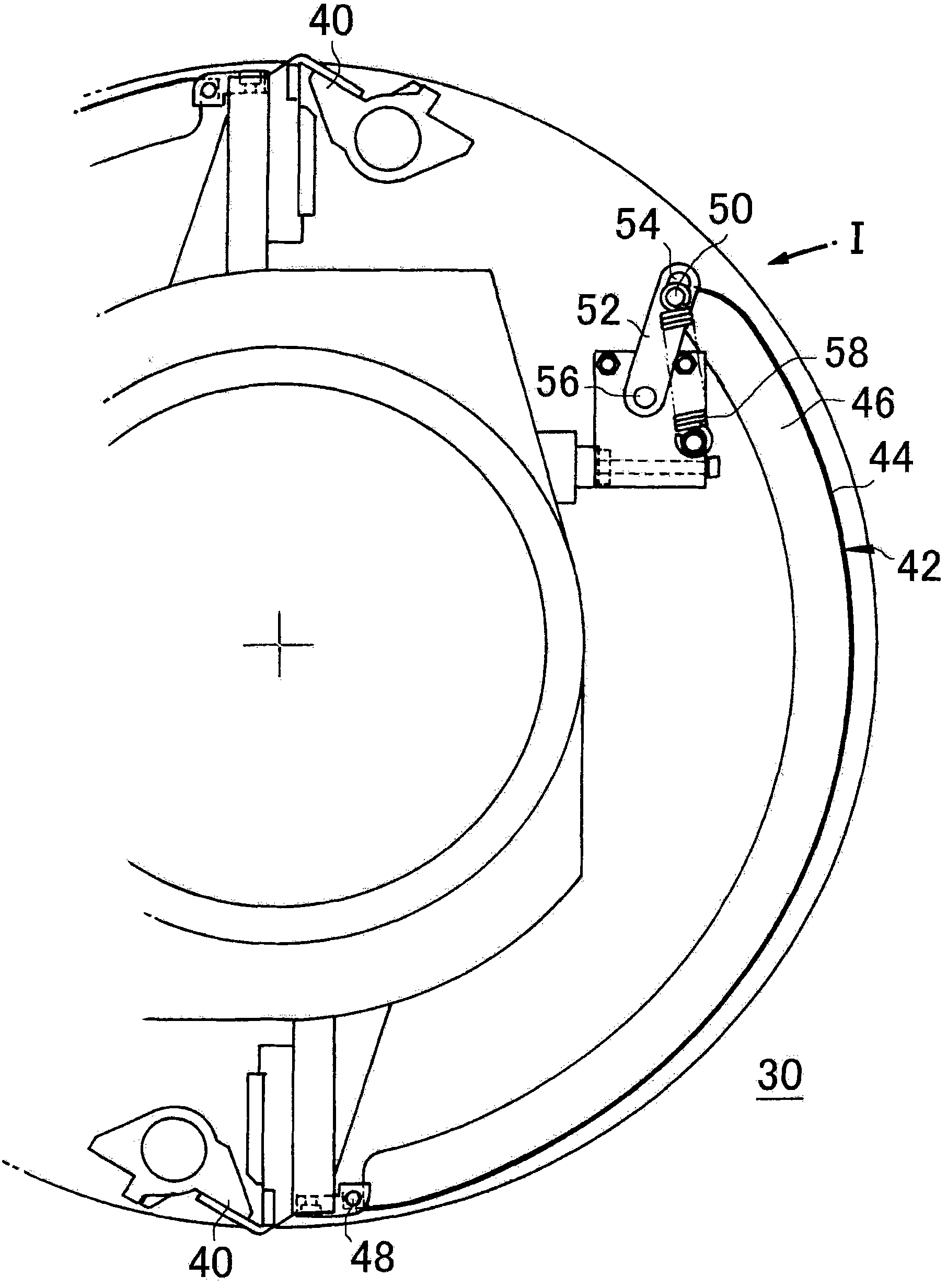

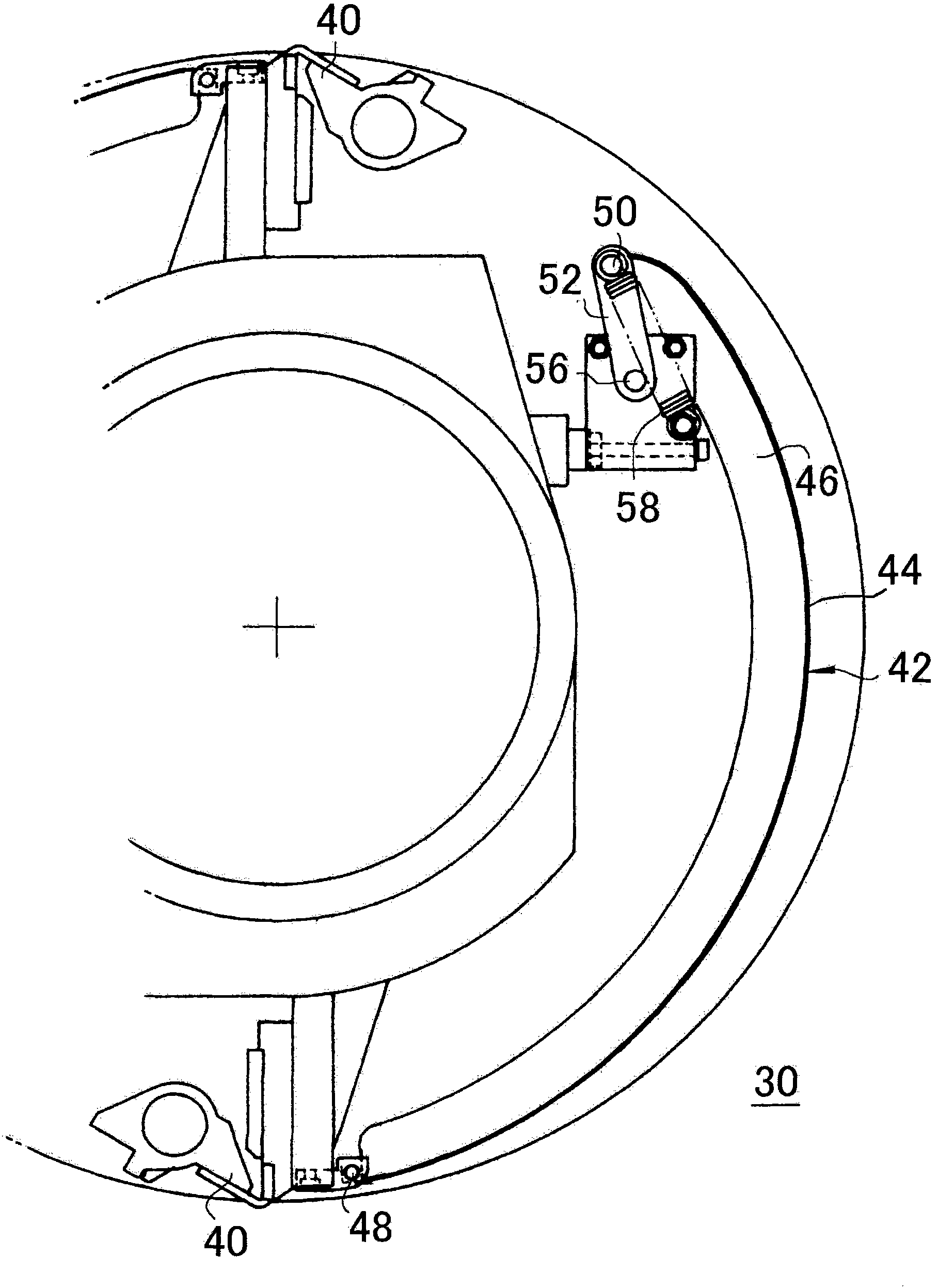

[0020] An embodiment of the sheet introducing device of the present invention will be described in detail below with reference to the accompanying drawings. In a sheet-fed printing machine that sequentially overlaps and prints black, cyan, magenta, and yellow colors on a finalized sheet, the printing units 10 of each color are prepared as separate standardized units, and the sheet travel direction ( figure 1 The side panels 12 on both sides are connected to each other from right to left.

[0021] And, as is known, between the side plates 12 on both sides, the plate cylinder 14, the blanket cylinder 16 and the impression cylinder 18 of double diameter are rotatably supported for offset printing. The cylinder 20 connects between the printing units 10 and constitutes a transport path for the sheet.

[0022] In addition, the double diameter here refers to having twice the diameter of the printing plate cylinder 14 on the basis of the diameter, which is a commonly used expression ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com