Full type roller bearing

A full-roller, bearing technology, applied in the field of full-roller bearings, can solve the problems of large deformation of material material, poor anti-deformation ability, and deformation of sealing cover, so as to reduce the increase of the rolling space of the roller and enhance the ability to withstand heavy loads. Ability, Thickness Thickening Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing.

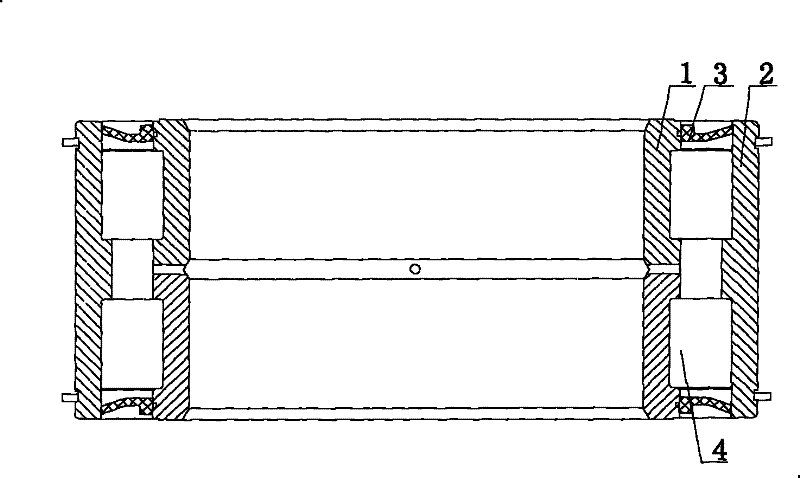

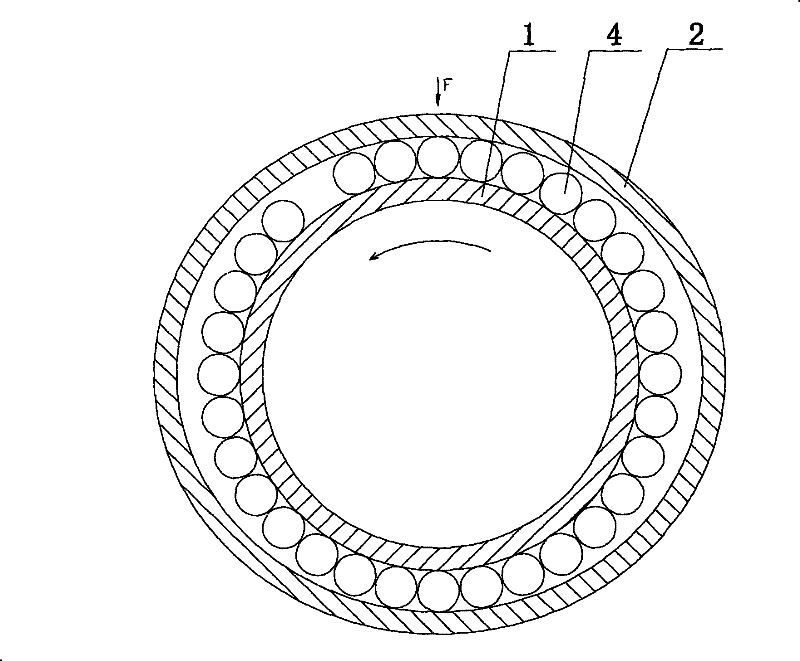

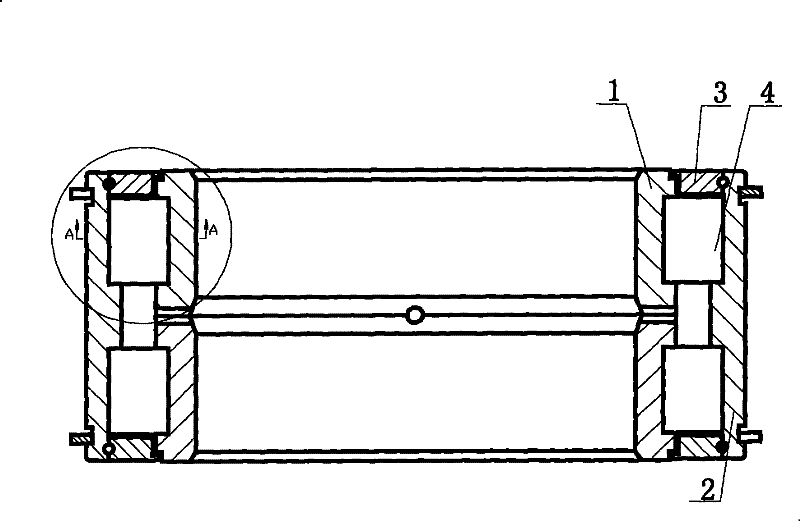

[0020] Such as image 3 , 4 As shown, a full roller bearing includes two inner rings 1 that are in contact with each other, an outer ring 2 arranged outside the inner ring 1, a sealing cover 3 and several rollers 4, the inner ring 1 and the outer ring 2 forms a double-row raceway that is compatible with the rollers. Both ends of the double-row raceway are covered with a sealing cover 3. The above-mentioned several rollers 4 are evenly arranged in the raceway according to the gap. The gap L of the rollers is 0.01-0.03mm, forming a self-locking structure of the rollers in the double-row raceway.

[0021] The sealing cover 3 is a metal dustproof cover, which is in transition fit to slight interference fit contact with the inner ring 1; the contact part between the sealing cover 3 and the inner and outer rings is provided with a sealing rubber layer.

[0022] In the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com