Reactor core cake production method

A production method and technology of core cakes, which are applied in the manufacture of inductors/transformers/magnets, circuits, electrical components, etc., can solve problems such as cumbersome production processes, noise, and reduction of magnetic cross-sections of core cakes, thereby reducing production costs , Solve the effect of loud noise and eliminate the noise source

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

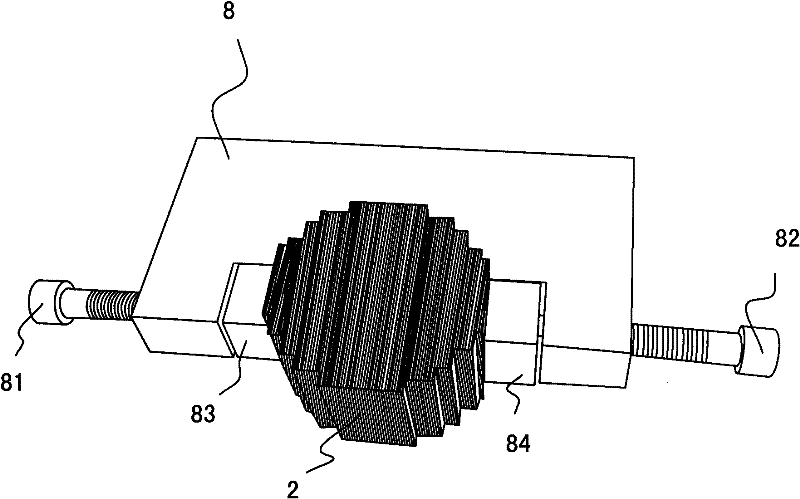

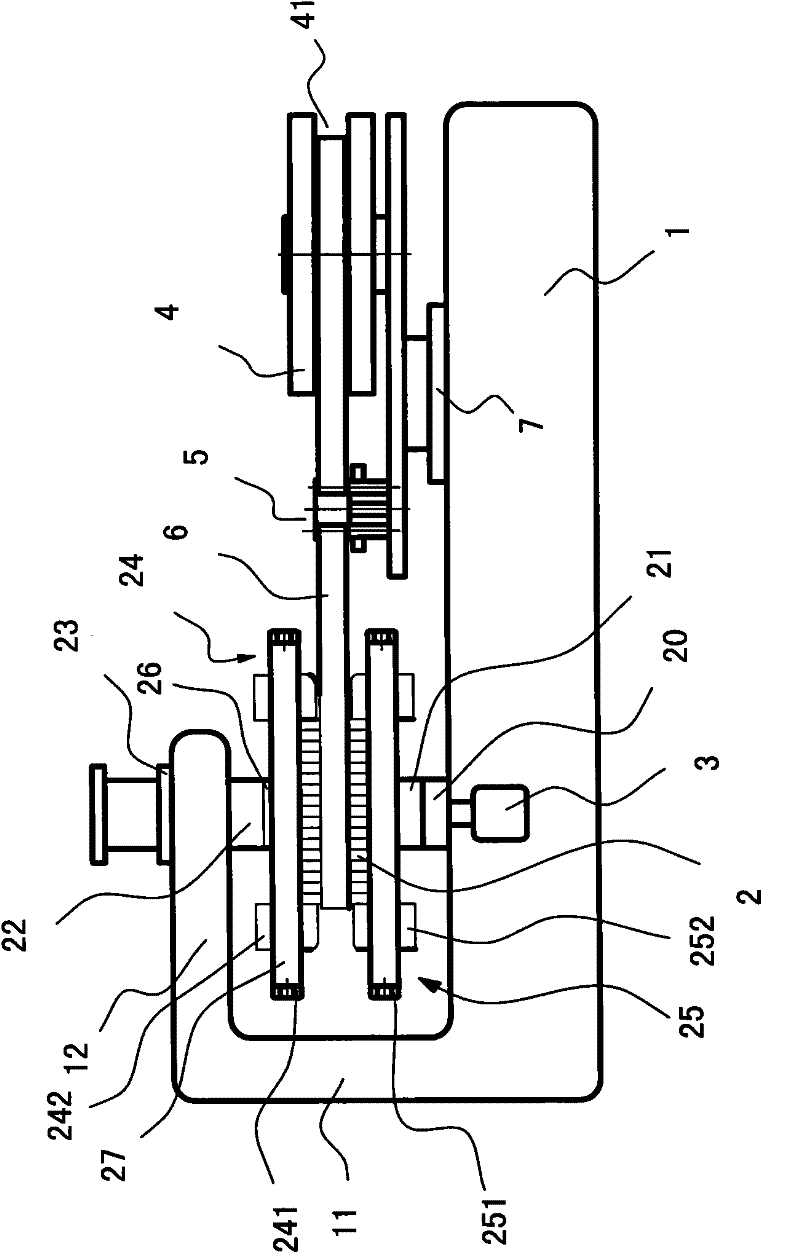

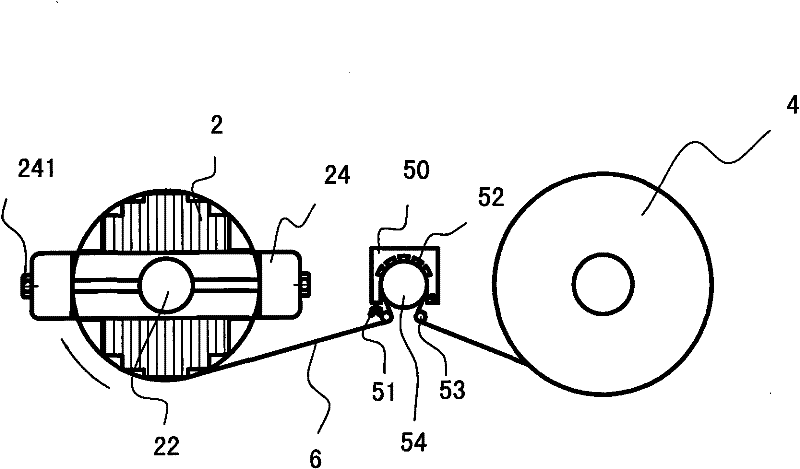

[0012] The manufacturing method of the reactor core cake of the present invention mainly includes the following steps: firstly adopting a forming fixture to organize and clamp many cut and scattered silicon steel sheets to form a silicon steel sheet cake, and then, together with the forming fixture, move the silicon steel sheet cake to a Clamp the silicon steel sheet cake between the upper and lower flat chucks that can drive the silicon steel sheet cake to rotate, and remove the forming fixture; drive the silicon steel sheet cake to rotate, and at the same time, the latitude-free belt around the silicon steel sheet cake is tensioned Under the action of force, the silicon steel sheet cake is pulled and bound, and after the set number of layers is wound as required, the tail of the non-weft tape is quickly cured at high temperature on the non-weft tape ring, and a one-time machine is bound to make the core cake blank; The core cake products are formed by vacuum fat-impregnating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com