Vegetarian lunch meat and preparation method and equipment thereof

A technology for luncheon meat and vegetarian food, applied in the fields of food preparation, food science, application, etc., can solve the problems of high water content, waste of resources, unfavorable long-distance transportation, etc., and achieve the effect of good taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) With 60% low-temperature defatted soybean powder, 10% glutinous rice flour, 12% soybean protein isolate powder, 10% low-temperature soybean meal powder and 8% bean dregs as raw materials, add 1% red yeast rice and 50% raw material weight mixed with water;

[0023] The low-temperature defatted soybean flour is obtained by extruding 12% of the fat in the soybean flour at low temperature;

[0024] The low-temperature soybean meal powder is soybean powder without oil;

[0025] Described glutinous rice flour is wheat gluten;

[0026] The bean dregs are bean cakes after making traditional tofu;

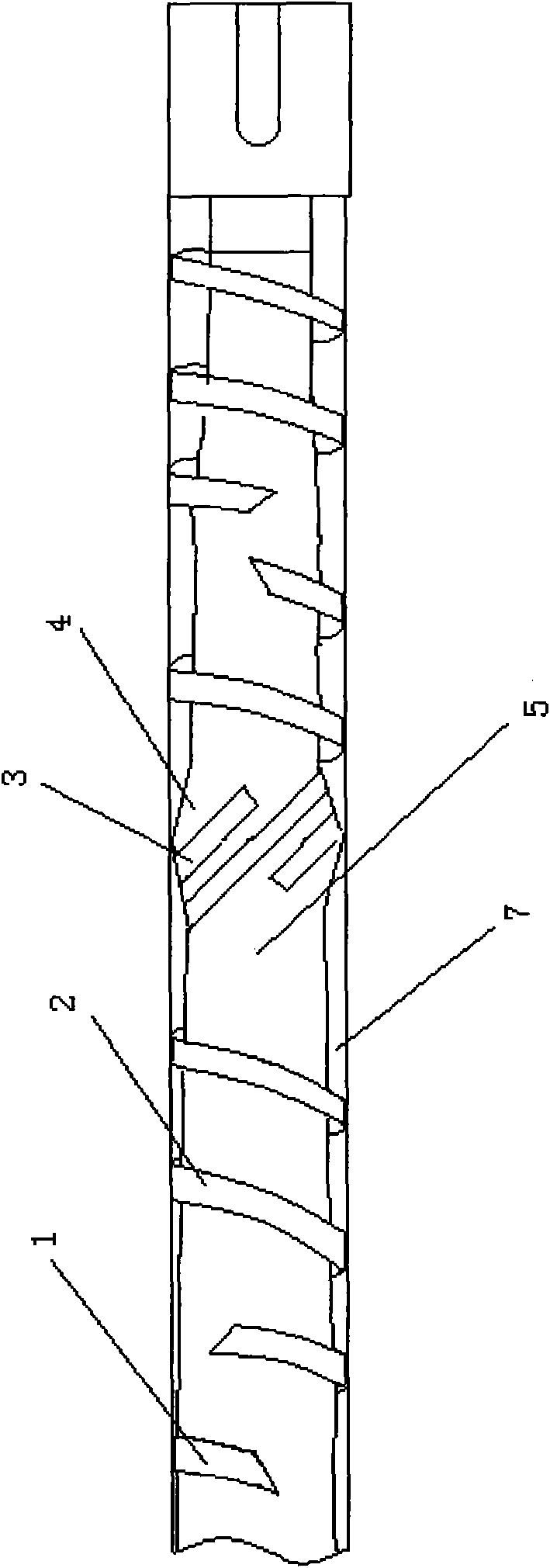

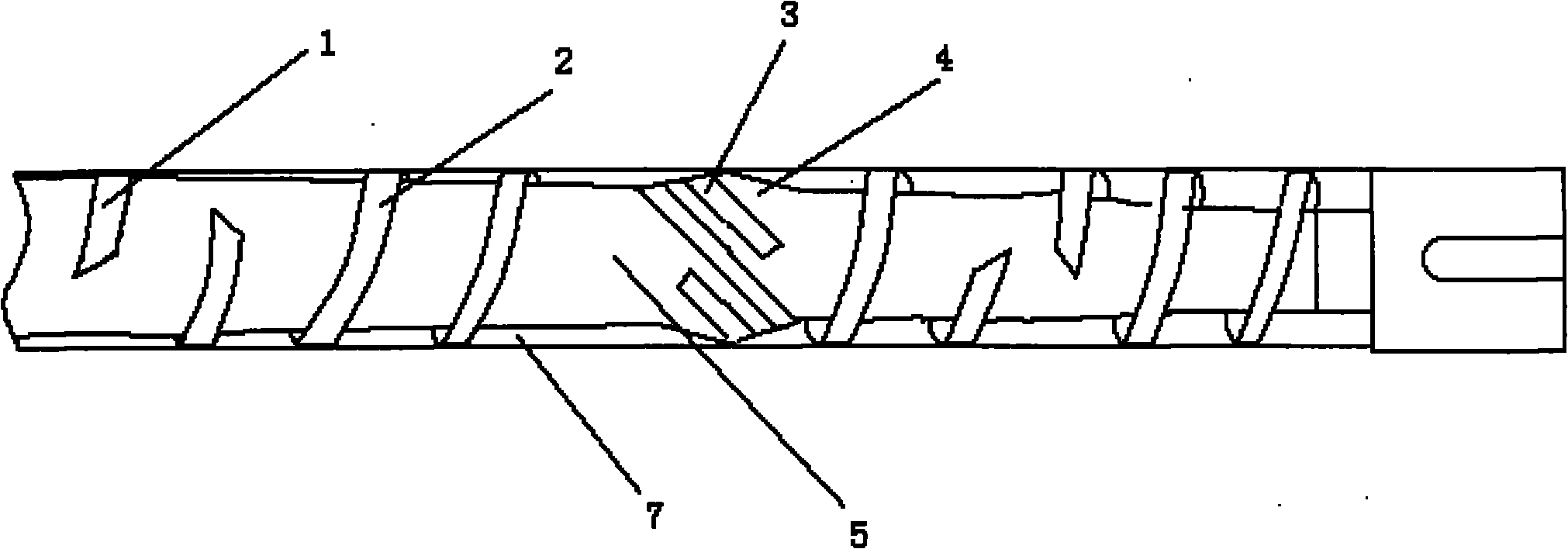

[0027] (2) In a sealed barrel with a screw, under the conditions of high temperature, high pressure, high shear force and the advancement of the screw, repeatedly mix, squeeze, and shear to change the fiber structure of the raw material and form meat-like fibers Structural blanks;

[0028] The pressure in the cylinder is 1.2Mpa; the temperature is divided into three sections:...

Embodiment 2

[0036] (1) With 70% low-temperature defatted soybean powder, 5% glutinous rice flour, 10% soybean protein isolate powder and 15% low-temperature soybean meal powder as raw materials, add 2% red yeast rice by weight of raw materials and 60% water by weight of raw materials to mix;

[0037] The low-temperature defatted soybean flour is obtained by extruding 10% of the fat in the soybean flour at low temperature;

[0038] The low-temperature soybean meal powder is soybean powder without oil;

[0039] Described glutinous rice flour is wheat gluten;

[0040] The bean dregs are bean cakes after making traditional tofu;

[0041] (2) In a sealed barrel with a screw, under the conditions of high temperature, high pressure, high shear force and the advancement of the screw, repeatedly mix, squeeze, and shear to change the fiber structure of the raw material and form meat-like fibers Structural blanks;

[0042] The pressure in the cylinder is 1Mpa; the temperature is divided into thre...

Embodiment 3

[0050] (1) With 65% low-temperature defatted soybean powder, 5% glutinous rice flour, 15% soybean protein isolate powder, 10% low-temperature soybean meal powder and / or 5% soybean dregs as raw materials, add 1 to 2% red yeast rice and 55% water by weight of raw materials is mixed;

[0051] The low-temperature defatted soybean flour is obtained by extruding 10-12% of the oil in the soybean flour at low temperature;

[0052] The low-temperature soybean meal powder is soybean powder without oil;

[0053] Described glutinous rice flour is wheat gluten;

[0054] The bean dregs are bean cakes after making traditional tofu;

[0055] (2) In a sealed barrel with a screw, under the conditions of high temperature, high pressure, high shear force and the advancement of the screw, repeatedly mix, squeeze, and shear to change the fiber structure of the raw material and form meat-like fibers Structural blanks;

[0056] The pressure in the cylinder is 1-1.2Mpa; the temperature is divided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com