Brush segment band

A brush section belt and strip technology, applied in the field of brush section belts, can solve the problems of brushes must be replaced, strips are damaged, brush section belts are not suitable for use, etc., and achieve the effects of simple replacement, simple turning back and guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

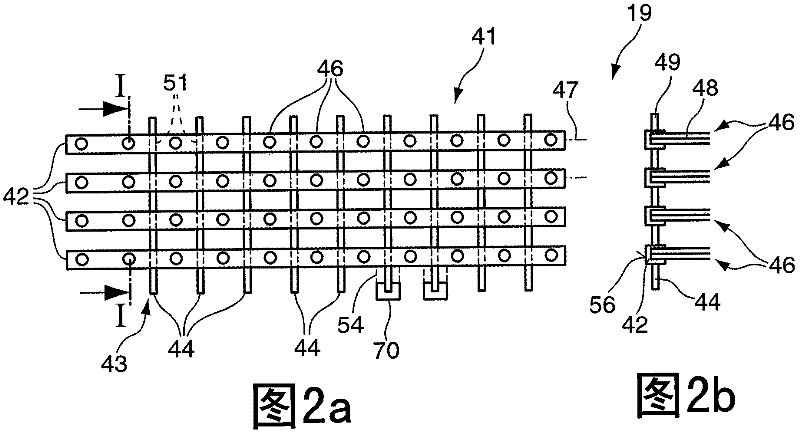

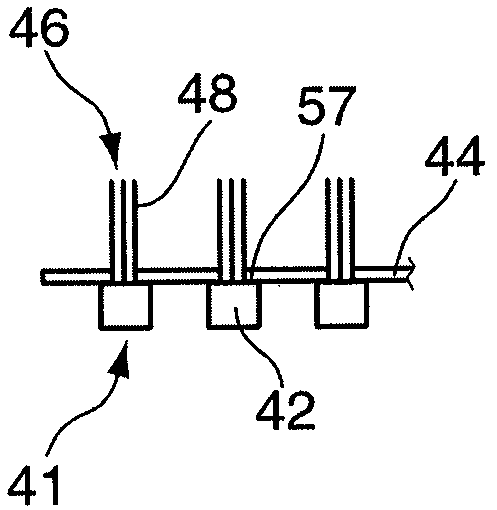

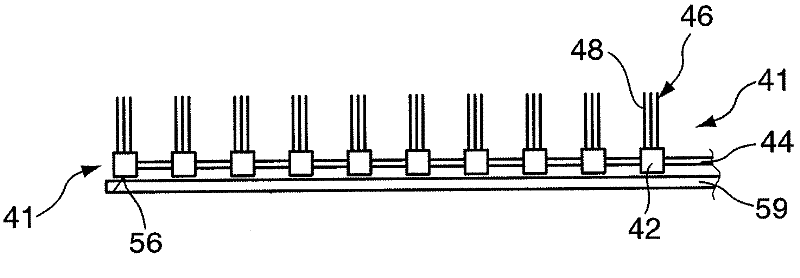

[0032] refer to figure 1 , shows a perspective view of the machine tool 11 . The machine tool 11 is preferably configured as a laser cutting machine. Alternatively, it can also be configured as a plasma cutter or flame jet cutter. The machine bed 12 includes first and second support surfaces 16 , 17 that together form a support table 14 . For example, the support surfaces 16 , 17 may be formed by common support strips 19 held fixed in the machine body 12 . Alternatively, the support belt 19 can also be movably driven and can additionally have a conveying function. It is also possible to arrange each support surface 16 , 17 so that it is provided with a separate support strip 19 .

[0033] The cutting head 22 is movable in the Y direction via the linear axis 21 , which forms the working range of the cutting head 22 . It is also possible to provide a linear shaft movable in and against the X-direction. It is also possible to provide a linear shaft which is movable vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com