Engine based on vane-type metal-water reaction propulsion unit

A technology of propulsion and water reaction, which is applied in the directions of machines/engines, gas turbines, mechanical equipment, etc., can solve problems such as designing propulsion devices, and achieve the effects of improving the reaction rate, strengthening the disturbance, and being easy to control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in more detail below in conjunction with accompanying drawing example:

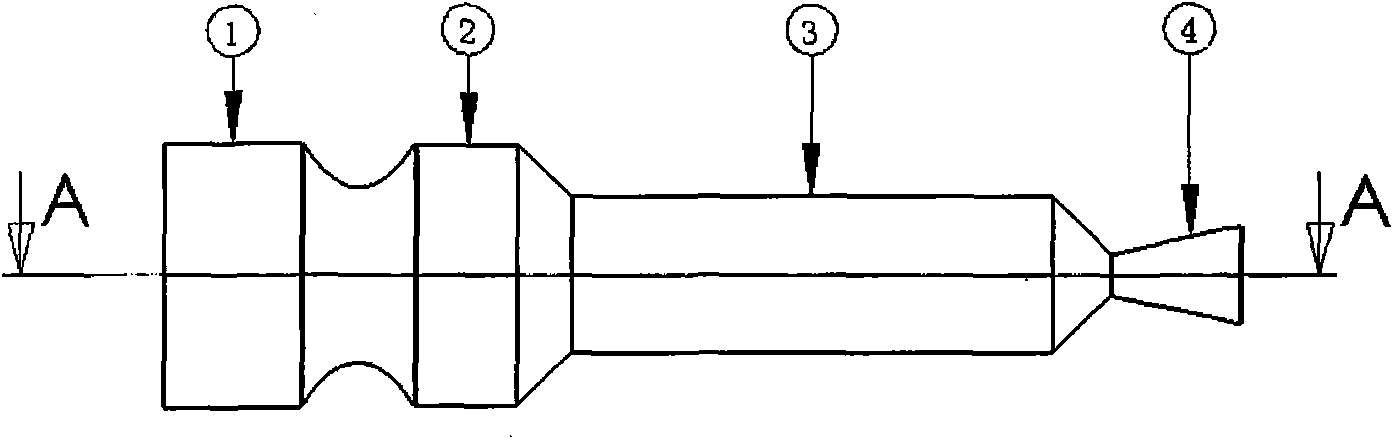

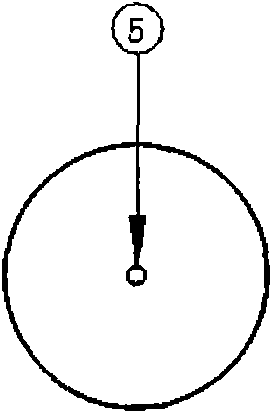

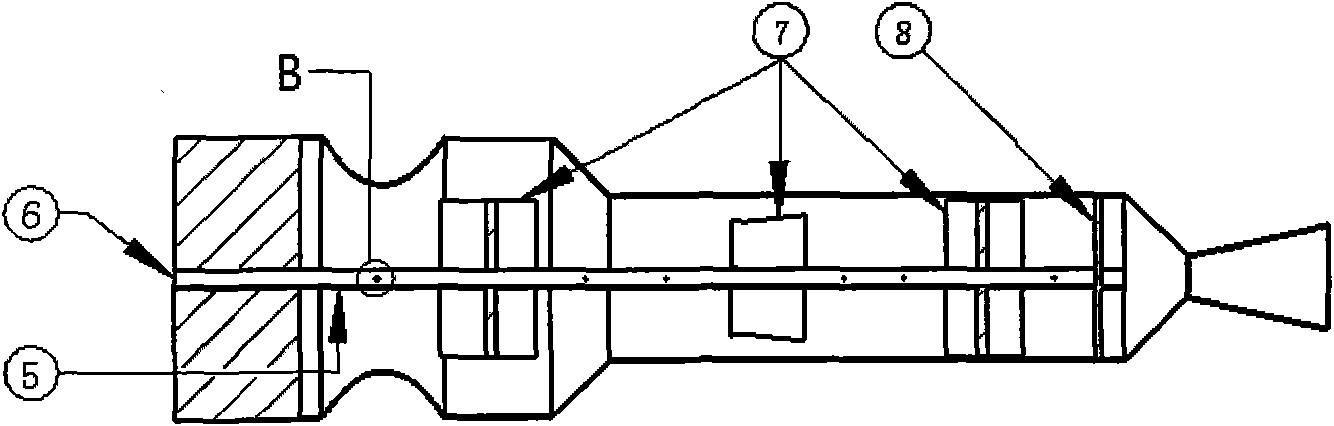

[0023] to combine Figure 1-11 , the present invention comprises a solid grain 1, a first combustion chamber 2, a second combustion chamber 3, a nozzle 4, a water inlet pipe 5 and a spiral blade 7, and the water inlet 5 passes through the solid grain 1, the first combustion chamber 2 and the second combustion chamber In the second combustion chamber 3, one end of the water inlet pipe 5 is installed in the solid powder column 1, and the other end of the water inlet pipe is installed on the rear side of the second combustion chamber 3 through the water pipe support 8, near the position of the spray pipe 4, and the water inlet pipe 5 is provided with Water spray hole 9, screw blade 7 are installed on the water inlet pipe 5.

[0024] exist figure 1 Among them, the solid grain 1 is a propellant containing metal particles, and when the grain is ignited, a fuel-rich ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com