Transfer paper with anti-counterfeiting fuzzy holographic pattern and manufacturing method

A manufacturing method and technology for transferring paper, applied in papermaking, paper coating, surface covering paper, etc., can solve problems such as identification, achieve bright metal texture, ensure product quality and reasonable production process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

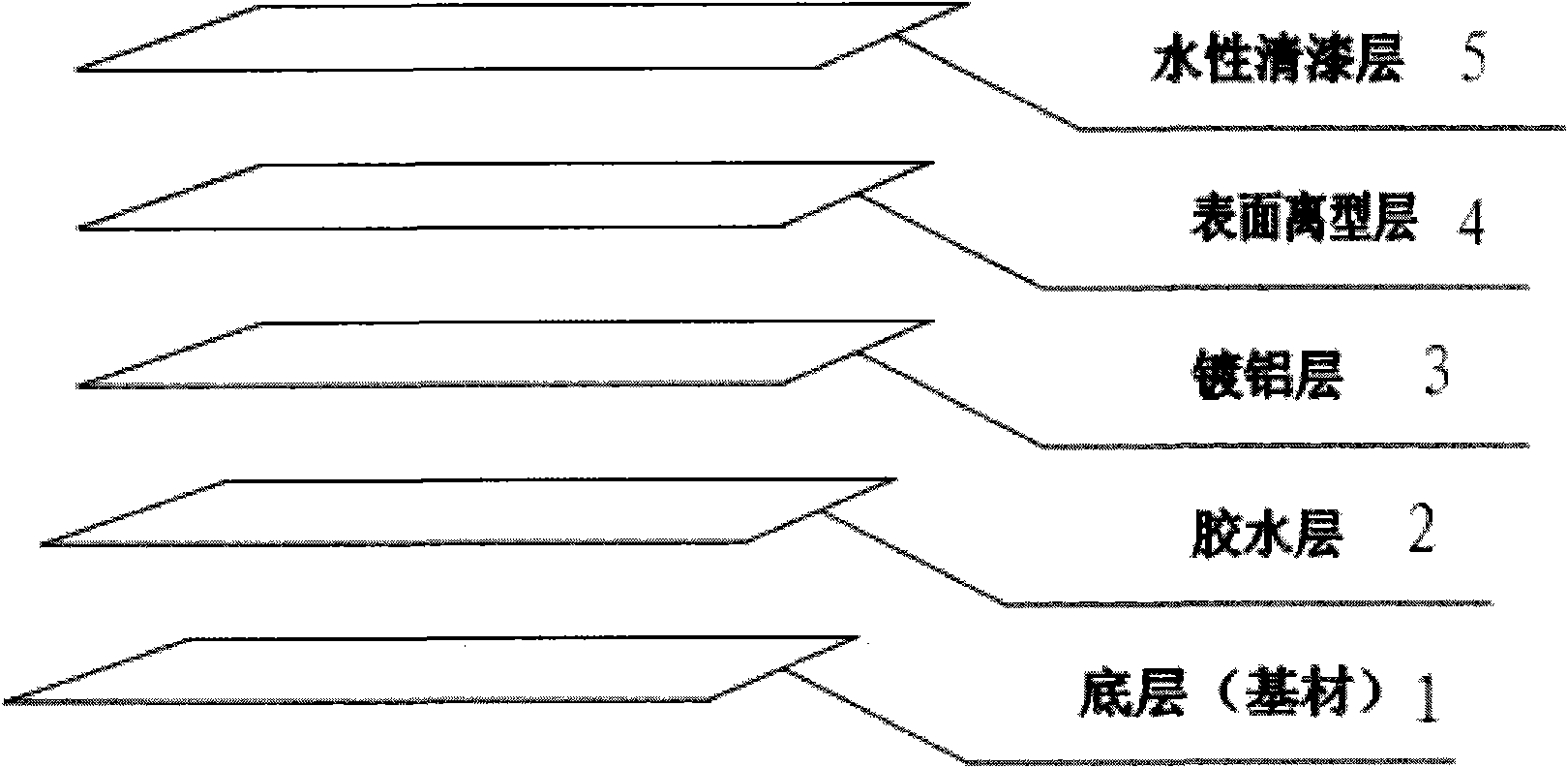

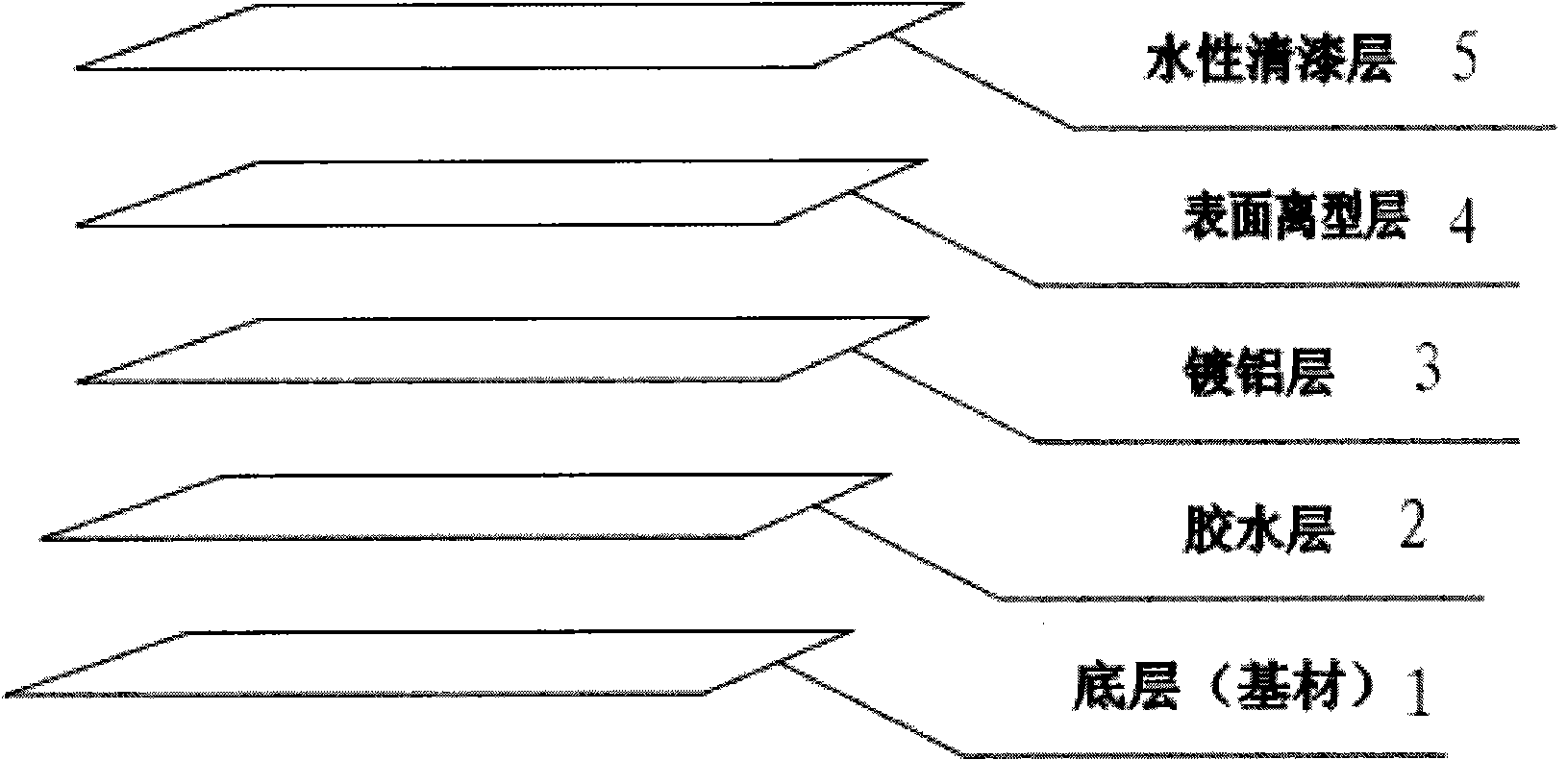

[0025] This example is manufactured as attached figure 1 The transfer paper with holographic fuzzy anti-counterfeiting pattern shown, the specific steps are as follows:

[0026] a. Coating: Biaxially oriented polyester film PET is used as the substrate, and a layer of polymer chemical release coating material is evenly coated on the substrate, and a transparent surface release with peelable properties is formed after drying and solidification Layer 4;

[0027] b. Plate making: the combination of holographic photography and laser plate making is used to make the molded metal plate have holographic fuzzy anti-counterfeiting patterns;

[0028] c. Molding: heat the plate roll to the molding temperature, and transfer the fuzzy pattern on the metal plate to the surface release layer 4 under the molding pressure so that the surface release layer 4 has exactly the same holographic blur as that on the metal plate Anti-counterfeiting pattern; Molding temperature: 175-185°C; Molding pr...

Embodiment 2

[0037] This example is manufactured as attached figure 1 For the transfer paper with holographic fuzzy anti-counterfeiting pattern shown, the specific steps are the same as those described in Example 1, only the two process parameters of molding temperature and molding pressure are changed. Molding temperature 180°C; Molding pressure: 2.4kgf / cm 2 ..

[0038] The transfer paper with holographic fuzzy anti-counterfeiting patterns produced is judged by imaging clarity, an important indicator of molding quality. The anti-counterfeiting pattern can be observed directly with the naked eye.

Embodiment 3

[0040] This example is manufactured as attached figure 1 For the transfer paper with holographic fuzzy anti-counterfeiting pattern shown, the specific steps are the same as those described in Example 1, only the two process parameters of molding temperature and molding pressure are changed. Molding temperature: 180°C; Molding pressure: 2.7kgf / cm 2 ..

[0041] The transfer paper with holographic fuzzy anti-counterfeiting patterns produced is judged by imaging clarity, an important indicator of molding quality. The anti-counterfeiting pattern can be observed directly with the naked eye.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com