Shell and manufacture method thereof

一种制作方法、壳体的技术,应用在对表面涂布液体的装置、电气设备外壳/柜子/抽屉、离子注入镀覆等方向,能够解决产品周期延长、产品良率降低、易形成点墨等问题,达到亮丽金属质感、产品良率高、制程简单的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

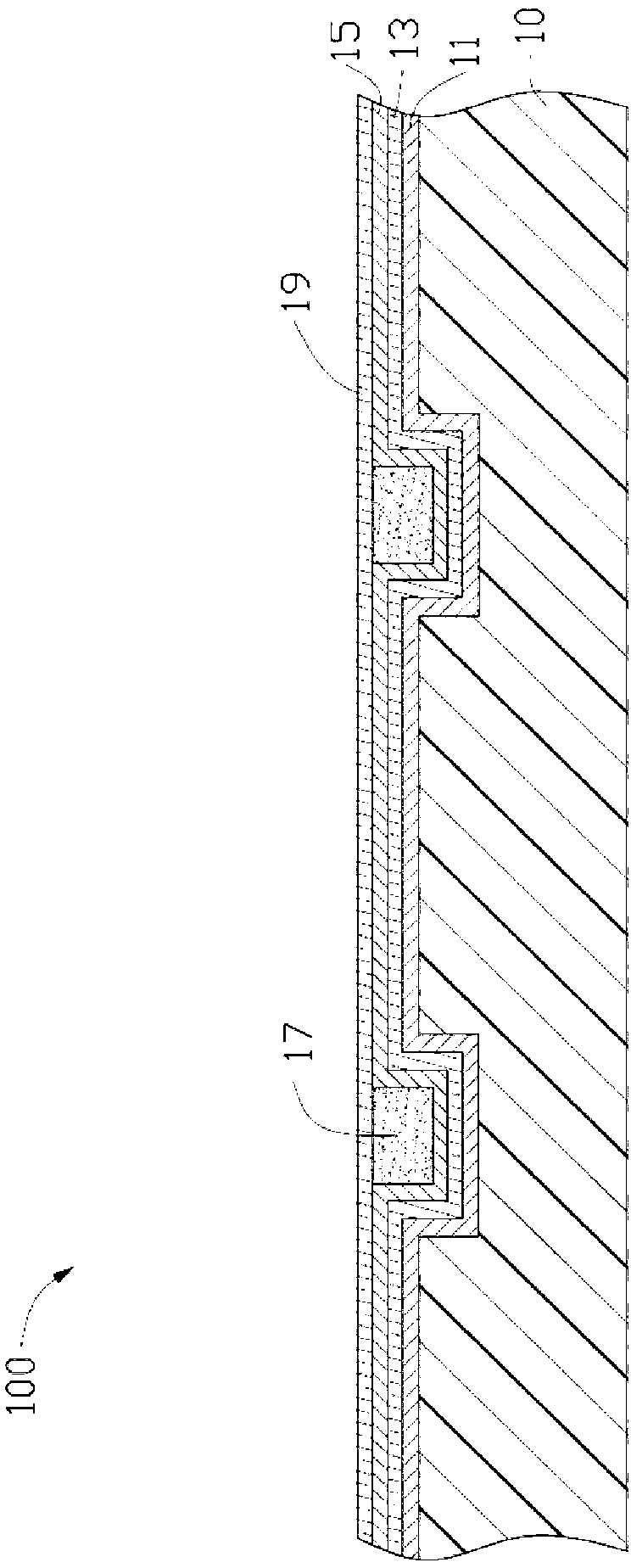

[0017] see figure 1 As shown, the housing 100 of the preferred embodiment of the present invention includes a substrate 10, a primer layer 11 formed on the substrate 10, a vacuum coating layer 13 formed on the primer layer 11, a vacuum coating layer formed on the vacuum coating layer The color paint layer 15 on 13, a pattern layer 17 formed on the color paint layer 15 and the transparent topcoat layer 19 covering the surface of the color paint layer 15 and the pattern layer 17.

[0018] The base 10 is a plastic base, and its surface is preset with a recessed area, and the recessed area has a preset trademark shape such as a pattern, a word or a character. The recessed area can be formed by arranging corresponding protrusions in the mold of the injection molding base 10 , or can be formed by chemical etching after the base 10 is molded.

[0019] The primer layer 11 is directly formed on the surface of the substrate 10 having the recessed area, which can be a UV-curable paint o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com