Production method of dimethyl phosphite

A technology of dimethyl phosphite and production method, which is applied in chemical instruments and methods, compounds of elements of Group 5/15 of the periodic table, chemical/physical/physical-chemical nozzle reactors, etc. It is difficult to control, labor-intensive and other problems, so as to shorten the reaction time, improve the effective conversion rate, and avoid the side reaction of acid hydrolysis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

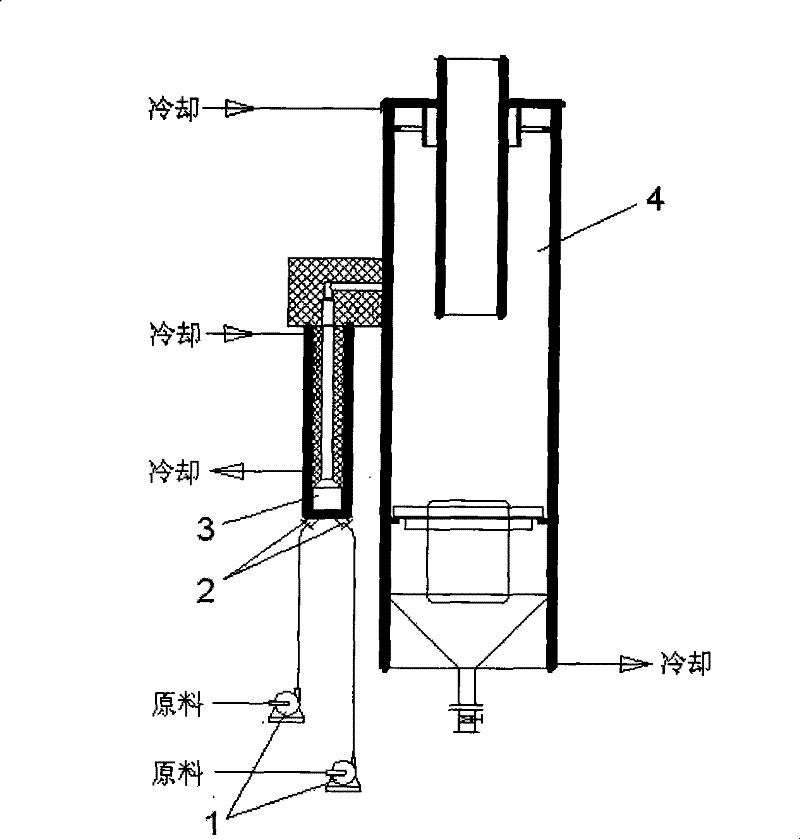

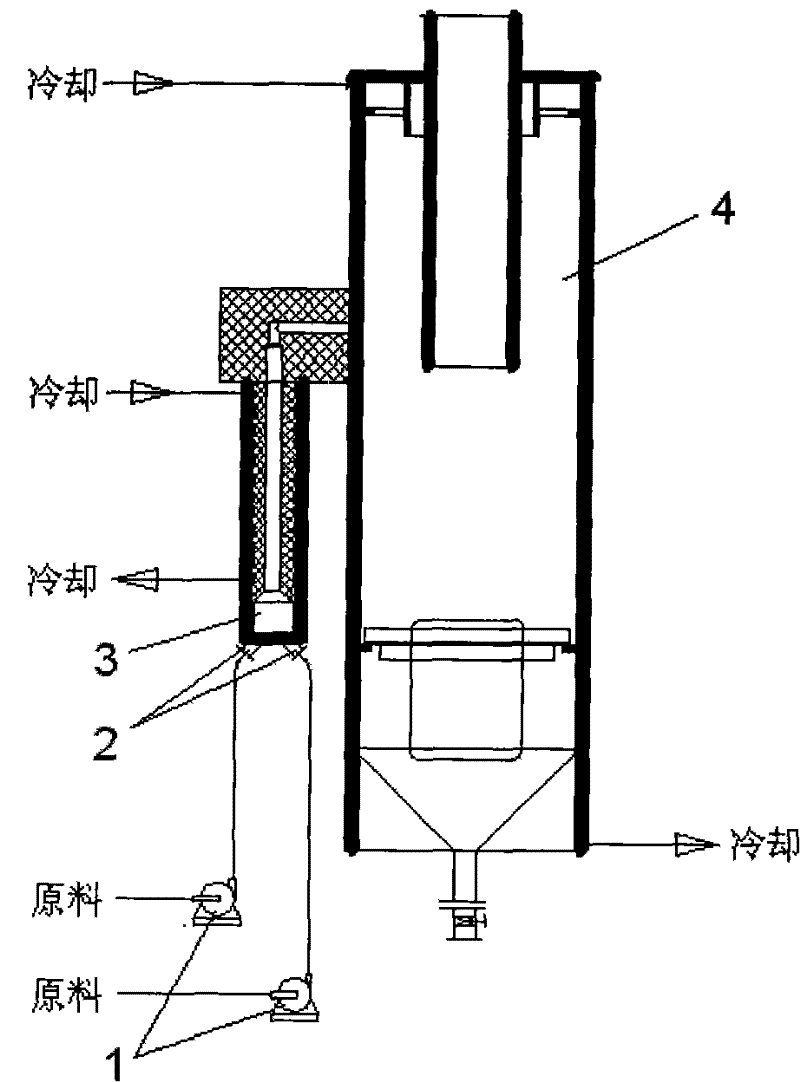

[0029] exist figure 1 In the shown device, methanol 810kg / h and phosphorus trichloride 1160kg / h are respectively metered by their respective metering pumps 1 and then continuously sprayed into the reaction tank with a high-pressure nozzle 2 at an angle of 70°. Reaction chamber space 3 of extension tube and cooling jacket structure. Under the action of the injection of the high-pressure nozzle 2, the pressure of the raw material entering the chamber space 3 of the reaction section is controlled at a gauge pressure of -0.085 to -0.090 MPa. Collide and mix with each other in a spray mode, and make the reaction materials enter the centrifugal cyclone (wind) separator 4 with a pressure of -0.090~0.092 (gauge pressure) along the reaction extension pipe at a speed of 8.5m / s along the tangential direction. Separation of liquid phase product dimethyl phosphite crude product and non-condensable gases such as HCl and methyl chloride at ~70°C. In the dimethyl phosphite crude product obt...

Embodiment 2

[0031] by two such as figure 1The same device of the structure shown constitutes a two-stage reaction scheme. The raw materials are 890kg / h of methanol and 1257kg / h of phosphorus trichloride, and after being metered by respective metering pumps 1, the full amount of phosphorus trichloride and 594kg of methanol are sprayed into the reaction chamber space 3 of the first-stage device. The included angle of the jet stream is 120°. The pressure of the primary reaction device is controlled at gauge pressure -0.075~-0.080MPa, the reaction temperature is controlled at 48~50°C, the speed of entering the cyclone (wind) separator is 5.5m / s, and the inner temperature of the cyclone separator is controlled at 75±1°C. The gauge pressure of the second-stage reaction device is -0.085~-0.090MPa, the included angle of the jet flow is 90°, the reaction temperature is 50~53°C, the velocity entering the cyclone (wind) separator is 7.5m / s, and the inner temperature of the cyclone separator Contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com