Toggle type nose wheel steering mechanism and work method

A front wheel turning and torsion arm technology, which is used in aircraft parts, landing gear, transportation and packaging, etc., can solve the problems of unstable rotation efficiency, large space occupied by the mechanism, and not stable transmission, so as to improve the ground maneuverability of the aircraft. The effect of reducing the space occupied by the mechanism and simplifying the nose landing gear system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

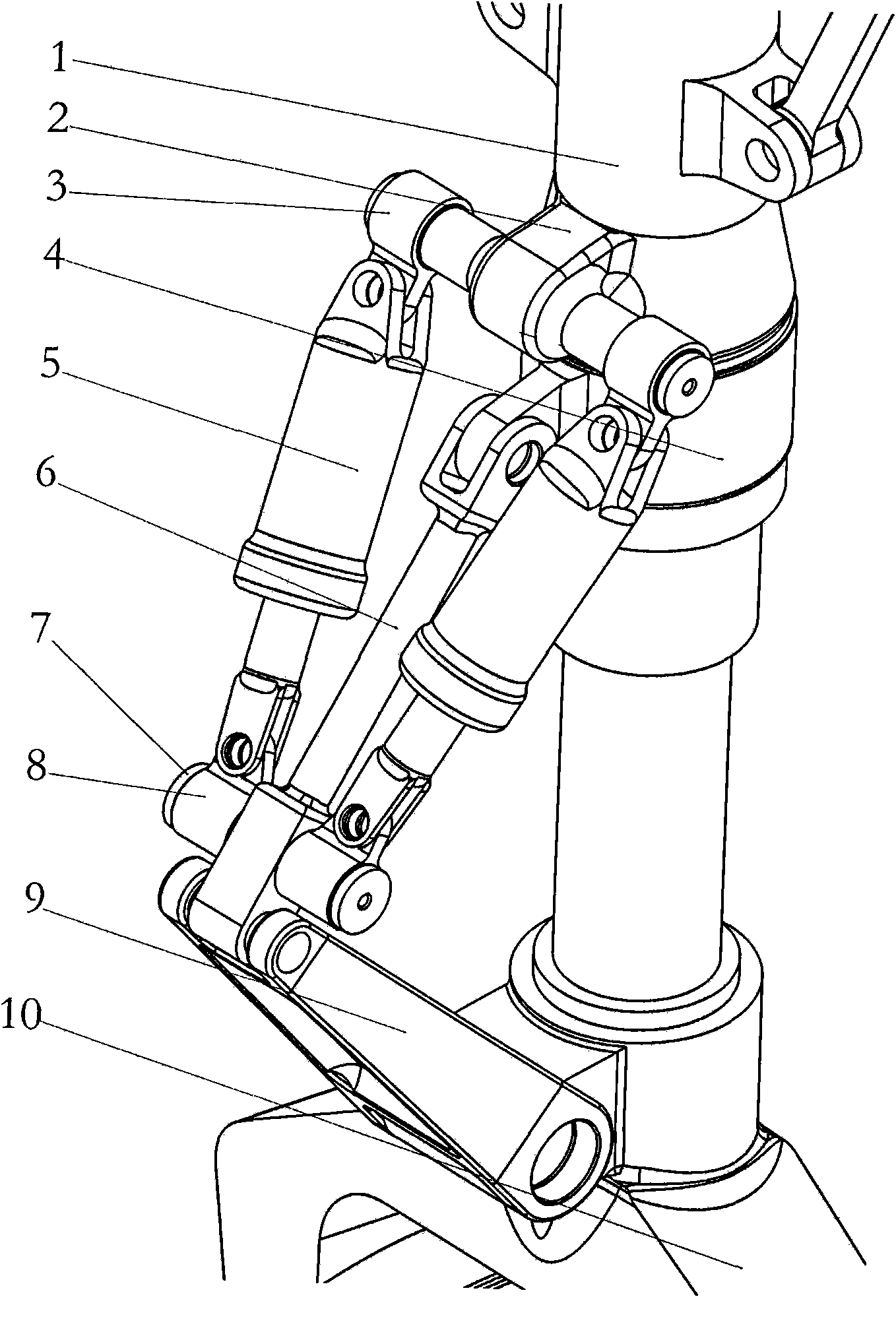

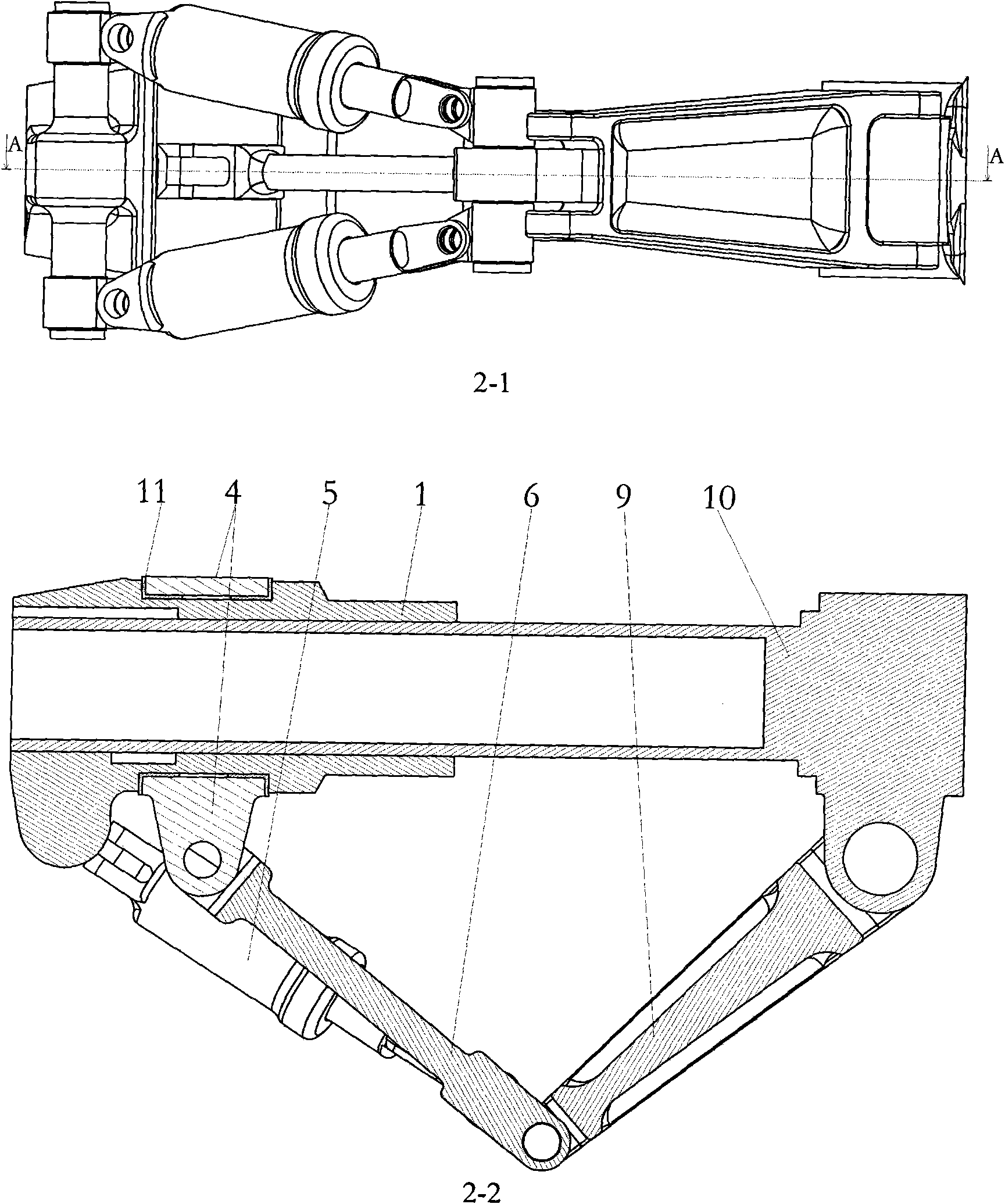

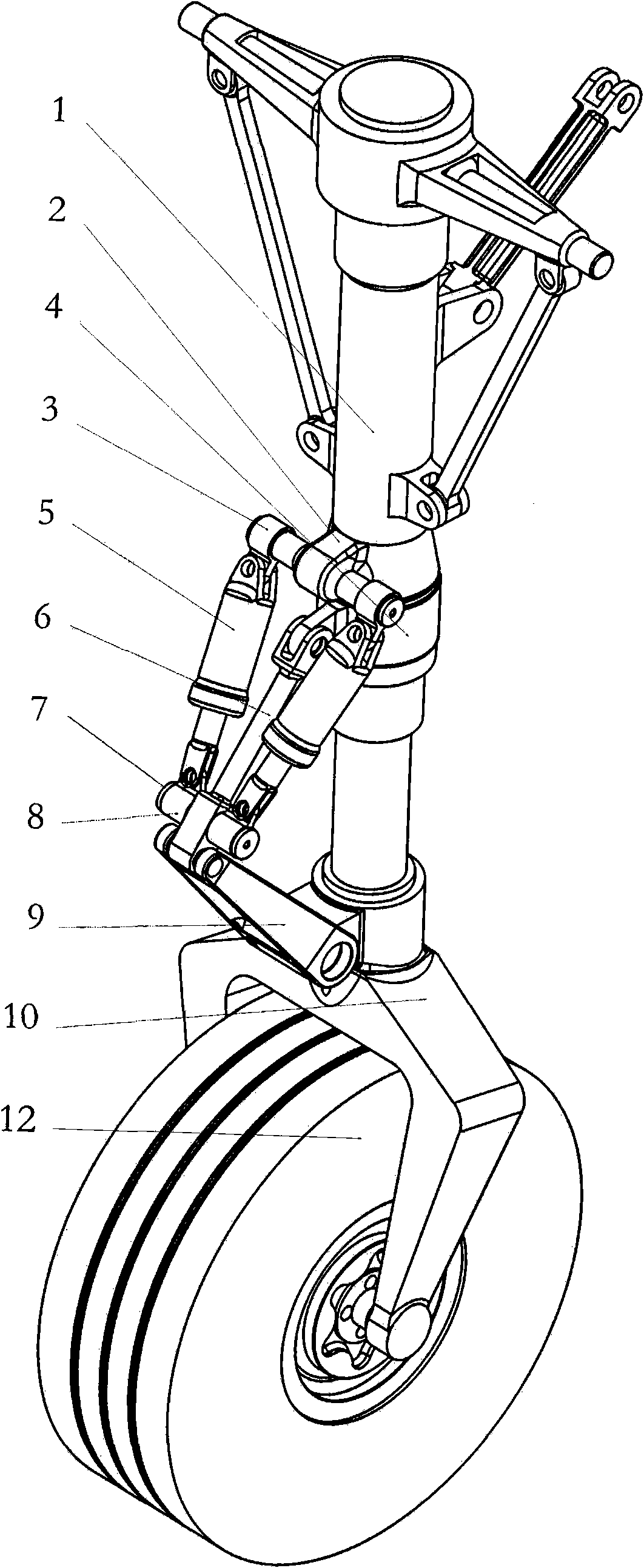

[0013] The torque arm type front wheel turning mechanism and its installation arrangement are attached figure 1 , 2 , 3 shown. The working principle of the present invention is briefly described here.

[0014] The pillar outer cylinder sleeve 4 is coaxially installed on the pillar outer cylinder 1 through the bearing washer 11, and is fixed in the axial direction through the upper and lower steps of the pillar outer cylinder 1, and the pillar outer cylinder sleeve 4 can be coaxial around the pillar outer cylinder 1 Rotate; the upper end of the upper connecting rod 6 is connected to the pillar outer cylinder sleeve 4 through a hinged manner, the lower end is connected to the upper end of the lower torque arm 9 through a hinged manner, and the lower end of the lower torque arm 9 is connected to the lower joint 10 of the pillar piston rod through a hinged manner; The rod 2 is fixed on the pillar outer cylinder 1, the lower cross bar 7 is fixed on the lower end of the upper link...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com