Process for the production of medium and high purity silicon from metallurgical grade silicon

A technology of metallurgical grade silicon and purity, applied in chemical instruments and methods, self-solidification method, silicon compound, etc., can solve the problems of not removing boron, not removing phosphorus, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0094] [Fe] solid =(1-0.50)·0.0000064·[Fe]liquid +0.50·[Fe] liquid = 0.50 [Fe] liquid

[0095] [P] solid =(1-0.50)·0.35·[P] liquid +0.50·[P] liquid = 0.68 [P] liquid

[0096] [B] solid =(1-0.50)·0.80·[B] liquid +0.50 [B] liquid =0.90·[B] liquid

[0097] Table 1

[0098] element

k eff

Al

Ca

co

Cr

Cu

Fe

Mg

mn

Mo

Ni

P

Ti

V

Zr

B

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.50

0.68

0.50

0.50

0.50

0.90

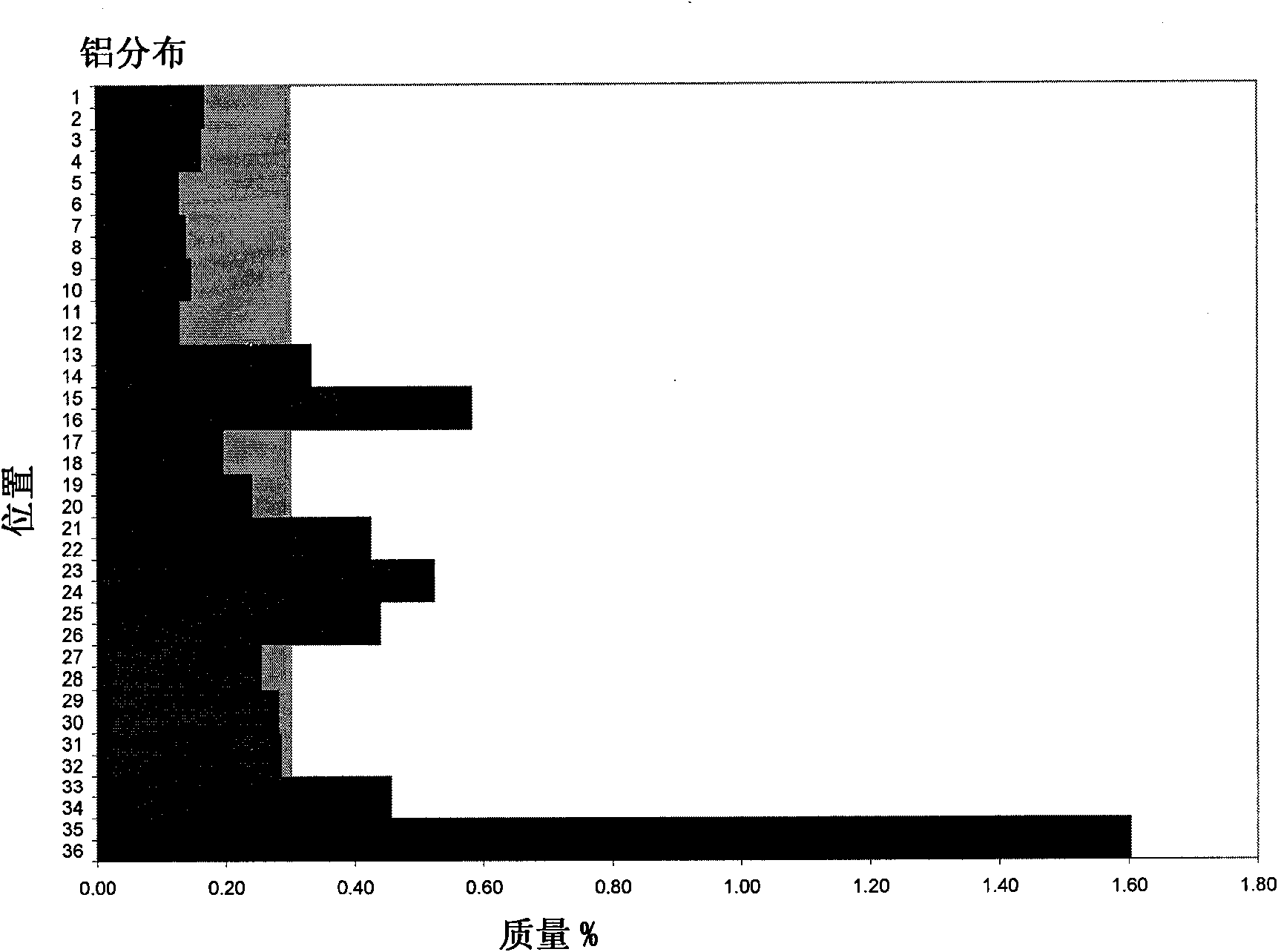

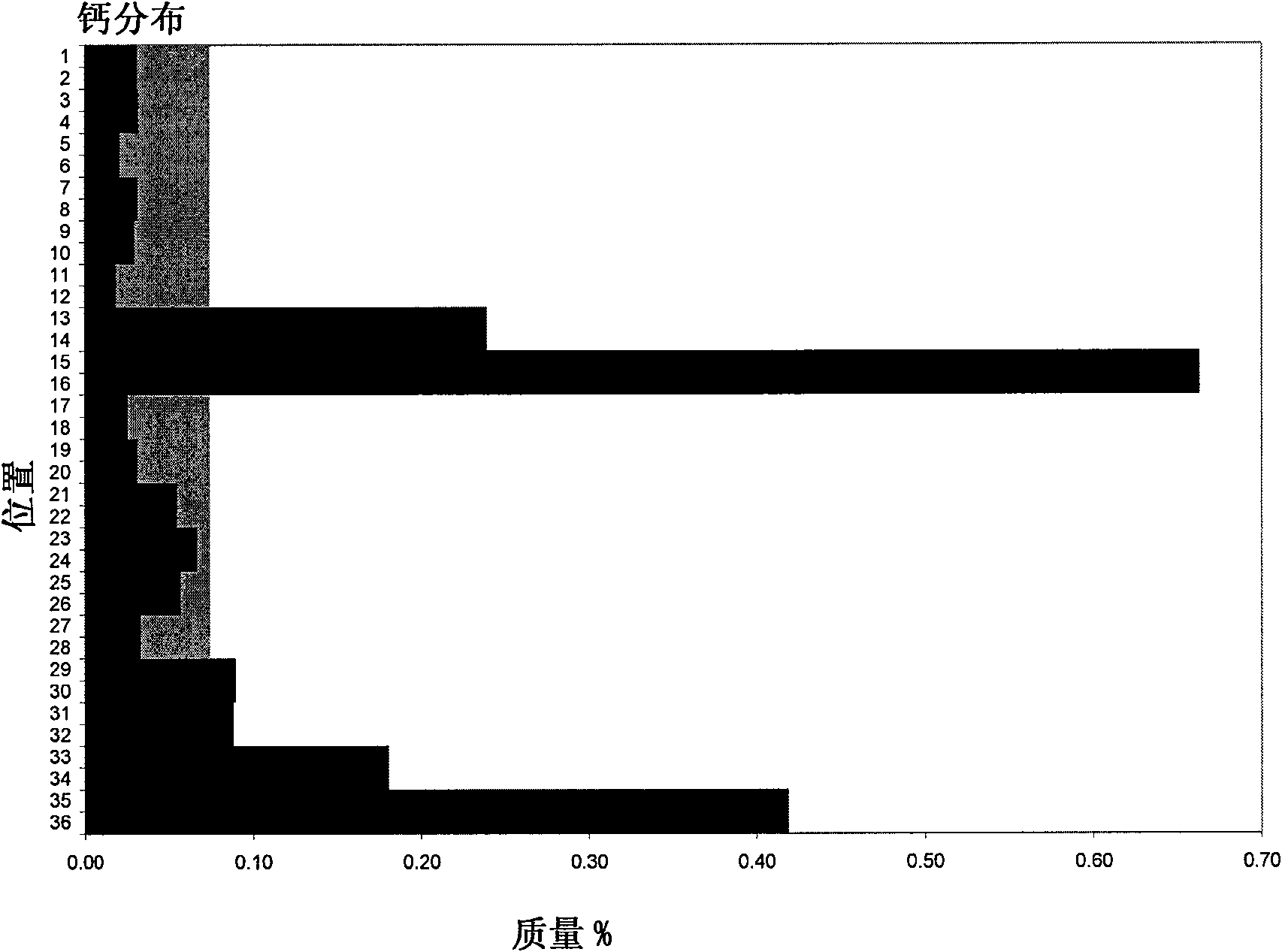

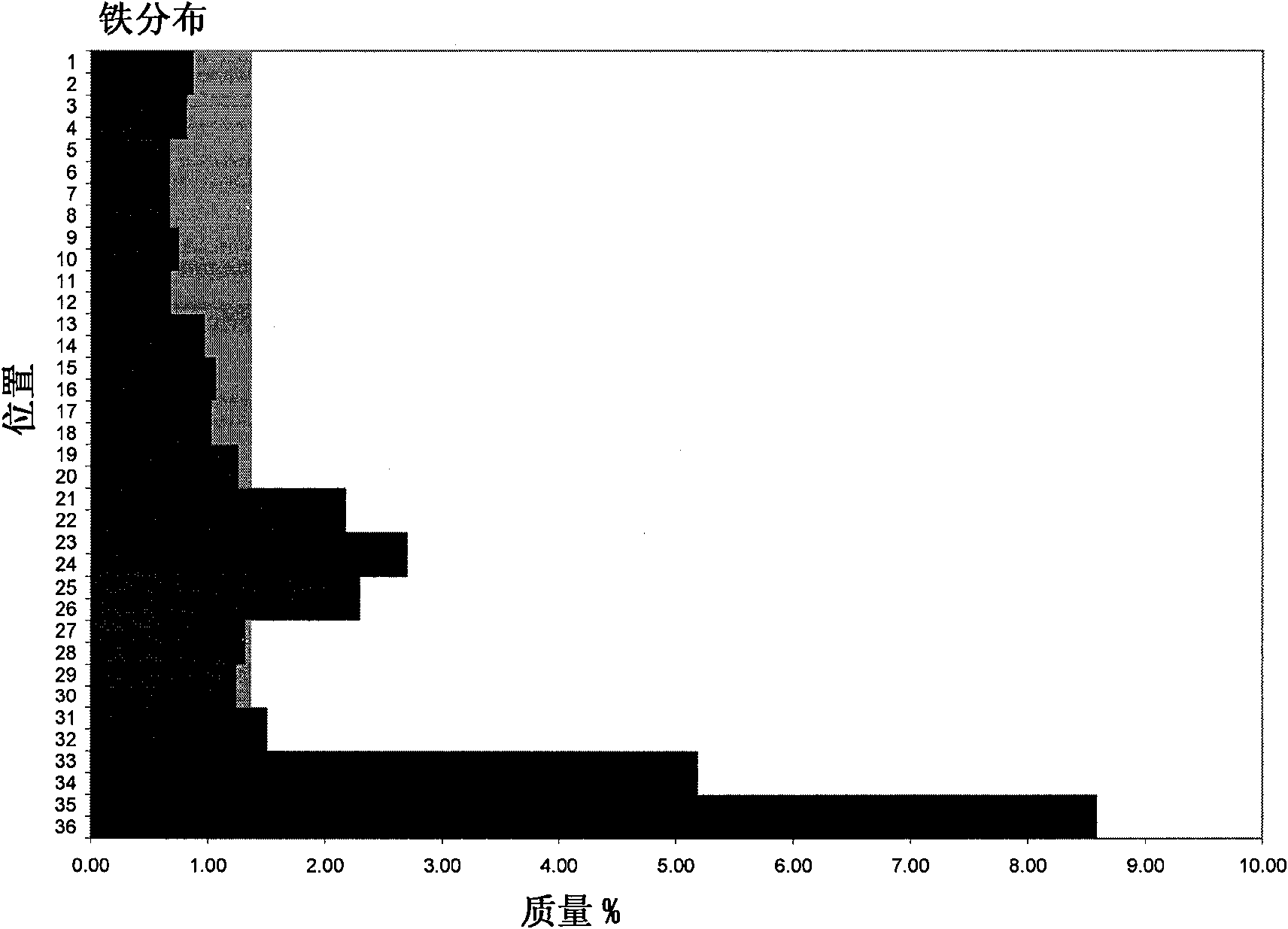

[0099] A purification efficiency of about 50% was obtained for most elements (except boron and phosphorus). In fact, approximately 30% of the phosphorus and 10% of the boron can be removed by the applicant's technique of large-mode segregation by directional solidification without electromagnetic stirring.

[0100] Distribution (segregation) coefficient (k eff ) remains the same during solidification, however, the composit...

Embodiment

[0118] The applicant wishes to obtain the iron concentration in solid and in liquid by solidification of 70% silicon melt (solidification time: 4.5 hours). The amount of liquid silicon was 5.0 mt and the composition of liquid silicon included 0.35% Fe.

[0119] k sol Fe = f ( k eff Fe , f s )

[0120] obtained from Figure 5 .

[0121] By considering the mass distribution, the applicant obtains:

[0122] k liq Fe = 1 - k sol Fe · f s 1 - f s = 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com