Optical lens

An optical lens and lens technology, applied in the field of optical lens, can solve the problems of insufficient fineness and clarity of the product, affecting the focus of ultraviolet laser, etc., achieve good three-dimensional sense and texture, improve energy concentration, and small focus point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

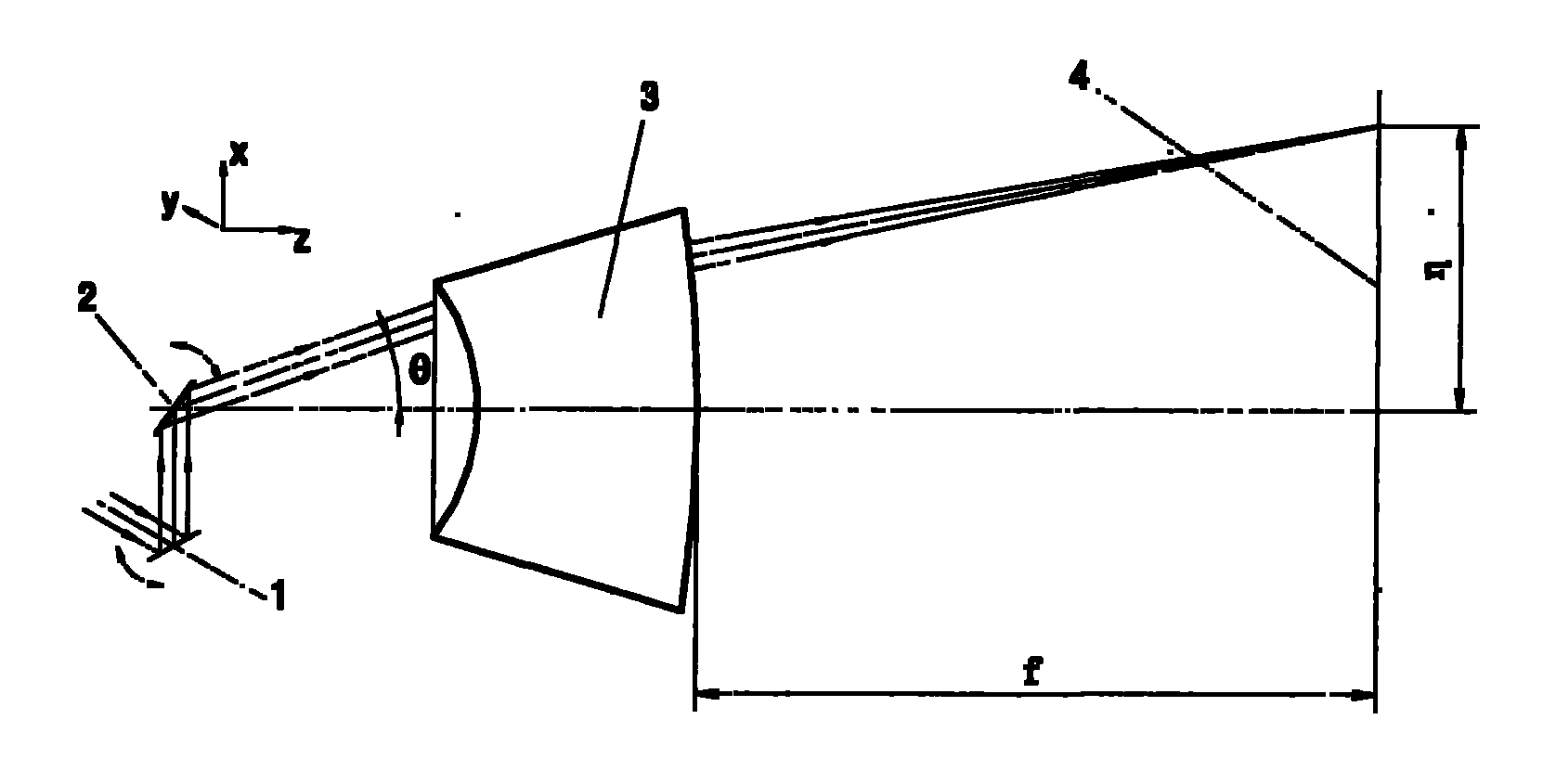

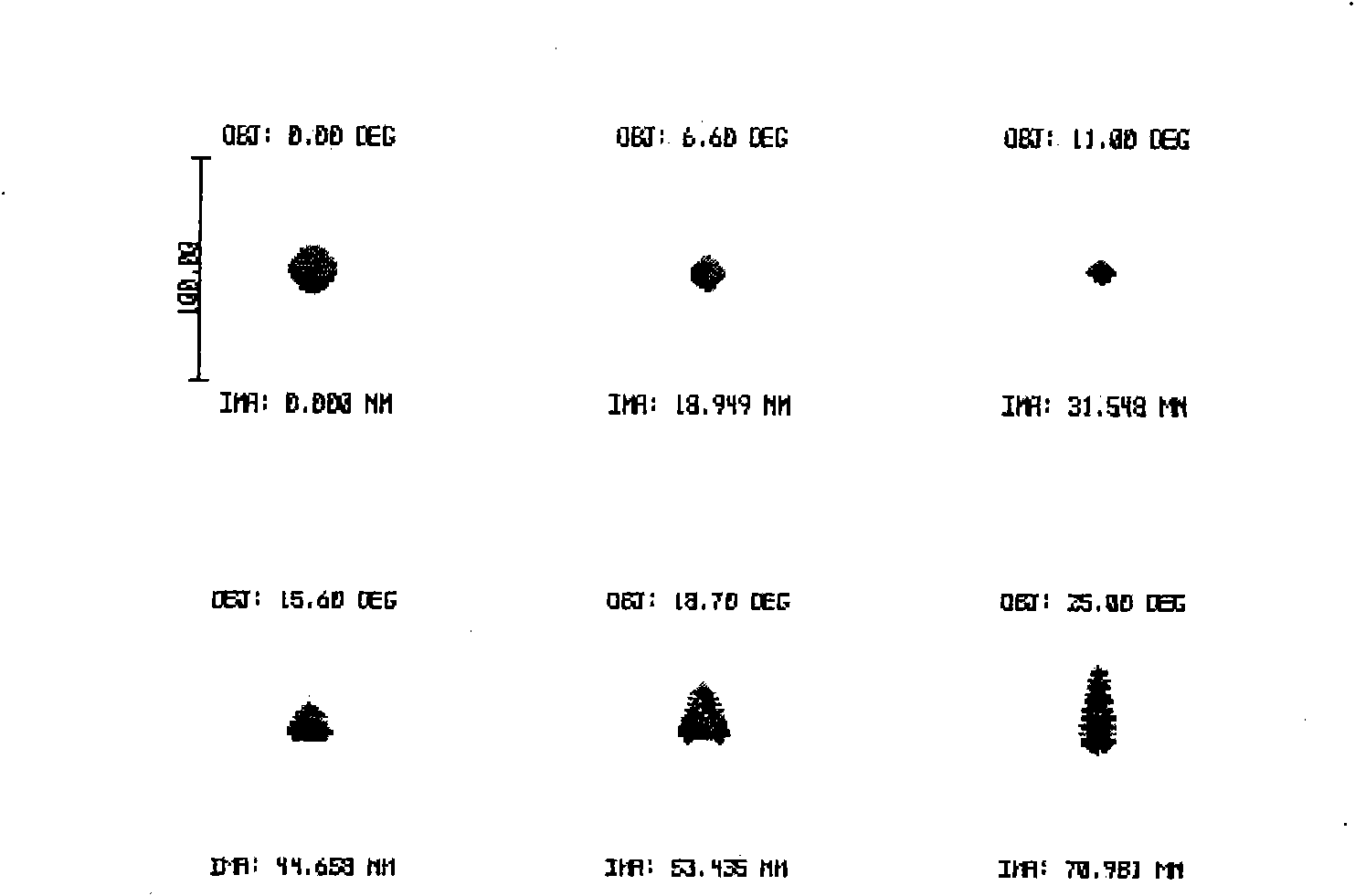

[0027] The first lens L1 is composed of two curved surfaces S1 and S2 whose radii of curvature are R1=-36mm and R2=270mm respectively, the central thickness d1=3mm on the optical axis, and the material is Nd1:Vd1 is 1.5 / 70; the second lens L2 is composed of two curved surfaces S3 and S4 with curvature radii of R3=-140mm and R4=-56mm respectively, the center thickness d3=6mm on the optical axis, and the material is Nd 3: Vd3=1.6 / 41; the third lens L3 It is composed of two curved surfaces S5 and S6 whose radii of curvature are R5=310mm and R6=-60mm, the center thickness d5=12mm on the optical axis, and the material is Nd5:Vd5=1.6 / 41; the first lens L1 and the second lens The distance between the lens L2 on the optical axis is d2=4mm, the distance between the second lens L2 and the third lens L3 on the optical axis is d4=0.1mm, and the distance between the third lens L3 and the first surface of the medium to be engraved is on the optical axis The spacing is d6=97-156mm, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com