Capacitance sensor calibration system for measuring very fast transient overvoltage (VFTO)

A capacitive sensor and transient overvoltage technology, applied in the direction of measuring electrical variables, voltage/current isolation, measuring devices, etc., can solve problems such as large difference in amplitude and steepness, insufficient voltage, and inability to meet VFTO response time , to achieve the effect of good test repeatability and less impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

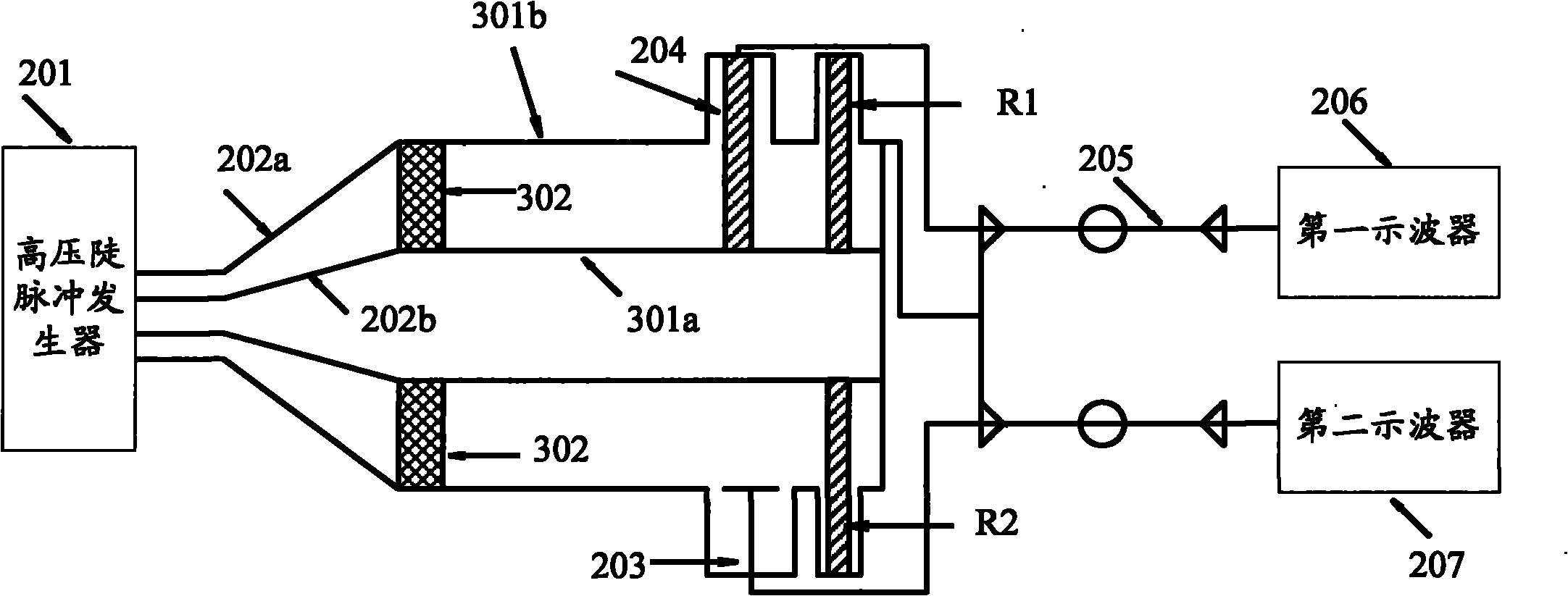

[0031] In order to enable those skilled in the art to better understand and implement the present invention, several technical terms are introduced below.

[0032] High-voltage steep pulse generator: a pulse voltage source with a small rise time (preferably 3 ns in the embodiment of the present invention), and a half-peak width reaching a certain requirement (about 100 ns in the embodiment of the present invention).

[0033] Conical transmission cylinder: a transmission line with variable radius, the wave impedance of which can gradually change (variable impedance line) or remain unchanged (equal impedance line is used in the embodiment of the present invention, that is, remains unchanged).

[0034] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

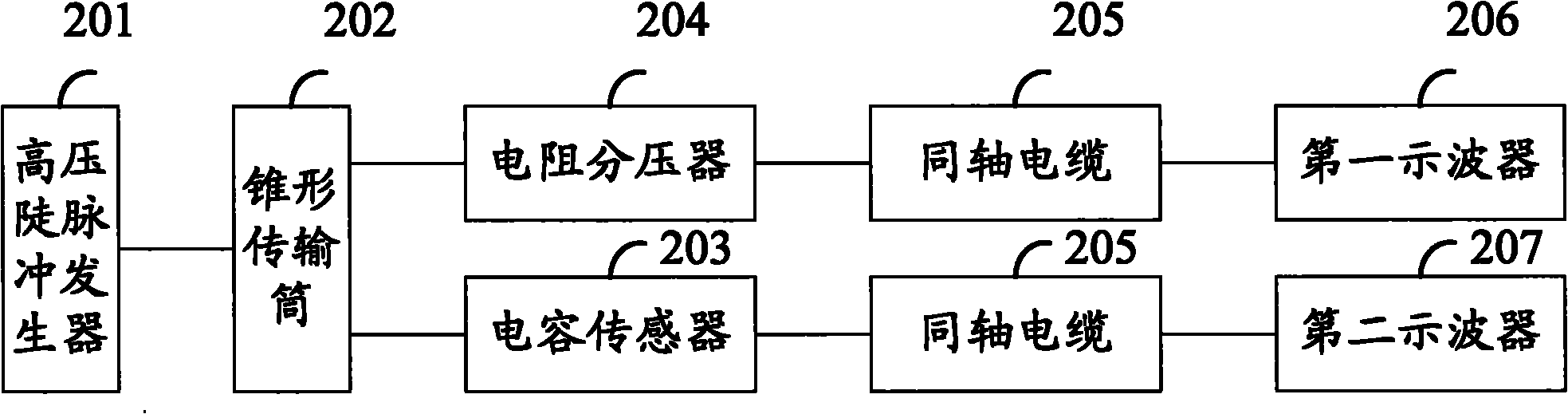

[0035] see figure 2 , which is a structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com