Method of health status diagnosis, early warning and fault location for protective layer of buried metal pipeline

A technology of safety early warning and positioning method, which is applied in the fields of early warning, detection of the health status of the protective layer of buried metal pipelines, and diagnosis. It can solve problems such as evaluation errors, differences in professional technical skills, and differences in cathodic protection potentials to ensure realizability , Guarantee the effect of long-term operation and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

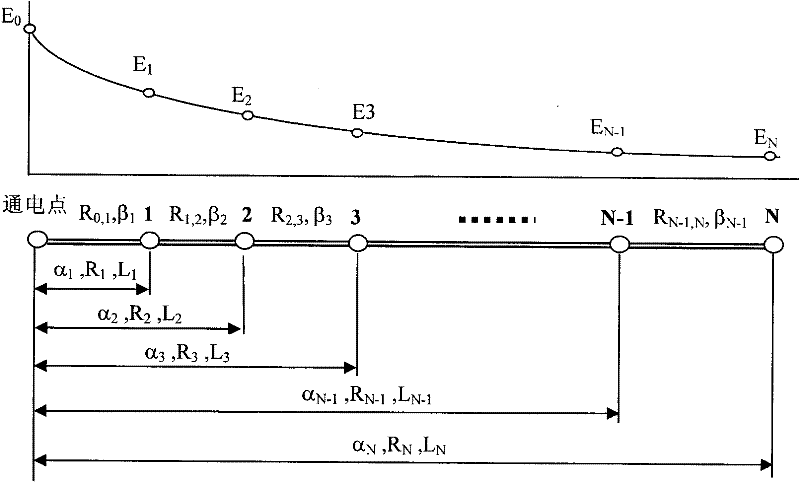

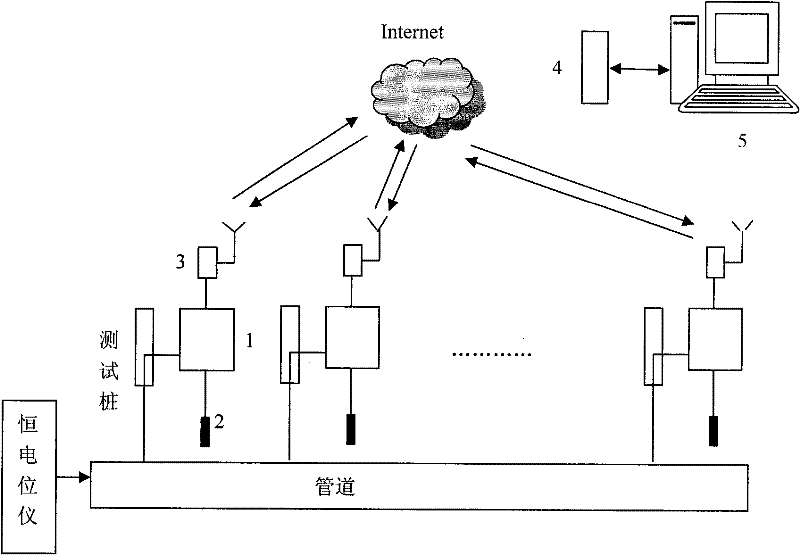

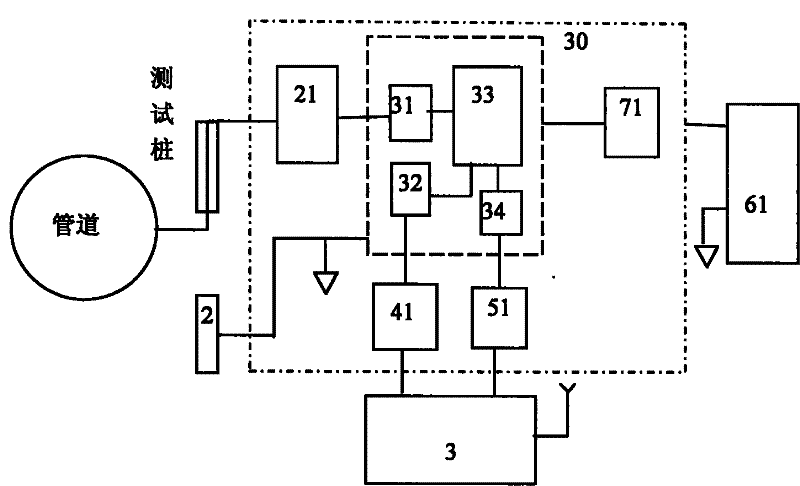

[0088] The technical route of the present invention is: install low-power consumption potential acquisition instruments at each test pile along the pipeline, and the potential acquisition instrument detects the cathodic protection potential of each test pile in the pipeline, and transmits the potential value, pipeline information, and stake number through the GPRS wireless transmission module Monitor the computer and store it in the database. The monitoring software evaluates the health status of the protective layer of each section of the pipeline according to the cathodic protection potential on each test pile and its distance from the energized point, and according to the difference between the two potential measurement results (potential drop value) before and after each test pile Whether the maximum value is greater than the threshold determines whether to issue a safety warning for the pipeline section and realize the location of the pipeline defect.

[0089] refer to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com