Heat exchanger with cold fluid and hot fluid not leak through with each other

A technology of hot fluid and cold fluid, applied in the field of non-leakage heat exchangers between cold and hot fluids, can solve problems such as equipment not operating normally, and achieve the effects of preventing mutual leakage, increasing heat transfer area, and enhancing heat transfer effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

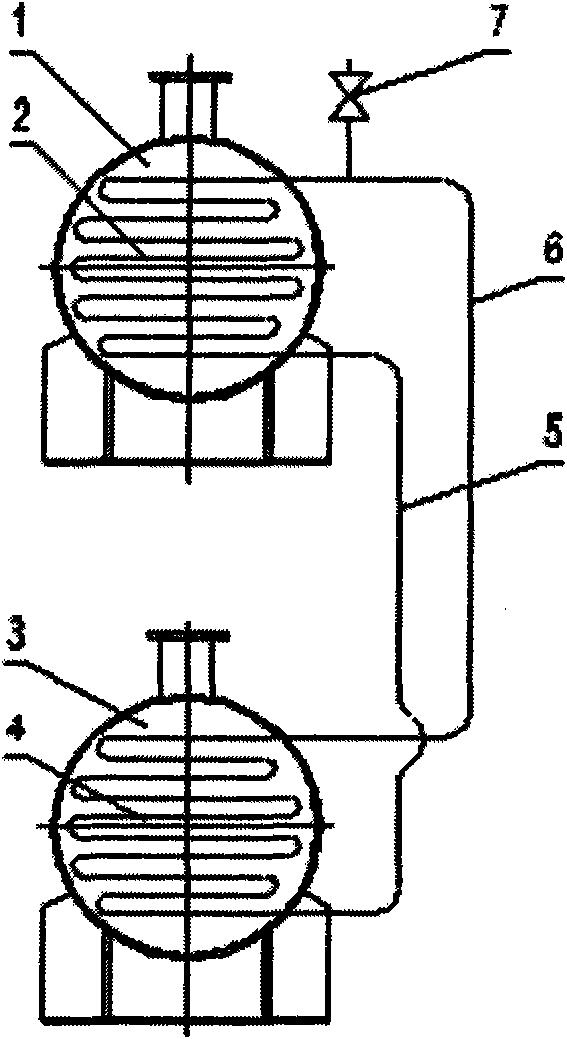

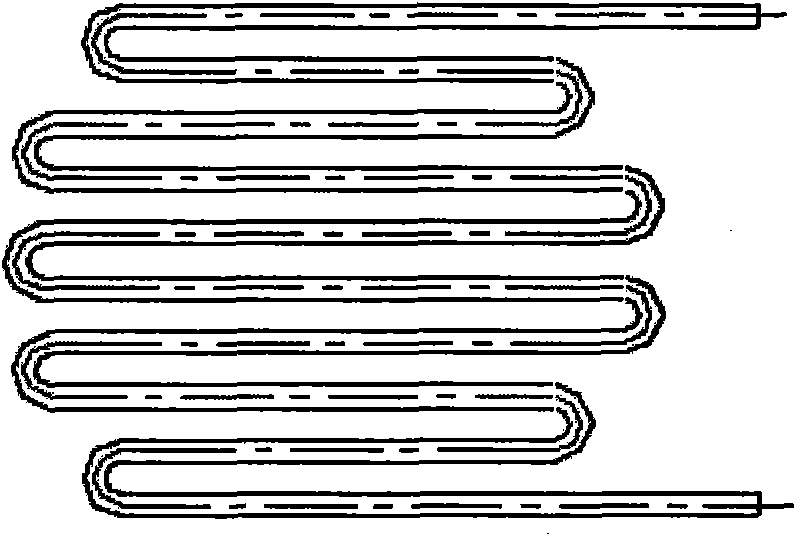

[0017] Such as figure 1 , 2 As shown, the heat exchanger is composed of cold and hot fluid containers 1 and 3, the cold fluid container 1 is at the high position, the hot fluid container 3 is at the low position, the shell side of the cold fluid container 1 passes through the cold fluid, and the shell side of the hot fluid container 3 Install the hot fluid inlet 9 on the top of the hot fluid container 3, install the hot fluid outlet 10 on the bottom of the hot fluid container 3, install the cold fluid inlet 11 on the top of the cold fluid container 1, and install the cold fluid inlet 11 on the bottom of the cold fluid container 1 through the hot fluid. The cold fluid outlet 12 is installed, several sets of condensation heat exchange tubes 2 are arranged in the cold fluid container 1, and several sets of evaporation heat exchange tubes 4 are arranged in the hot fluid container 3, and the lower ends of the condensation heat exchange tubes 2 are connected through the condensate r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com