Prestress steel rod intelligent anchoring system monitoring dynamic state of strengthening engineering preload

A prestressed steel and anchoring system technology, applied in bridge reinforcement, measuring devices, building reinforcements, etc., can solve the problems of rough loss judgment, low integration, affecting test accuracy, etc., to achieve fast operation and maintenance, and solution results. Precise, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

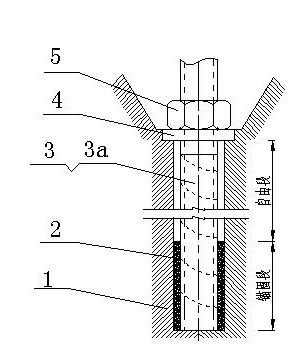

[0038] ①Constructors pre-locate and embed the anchorage system according to the design drawings of the prestressed reinforcement project, and determine the installation position and inclination angle. When the reinforcement project requires the steel rod 3 to be arranged in a curved line, the exposed section 6 of the prestressed steel rod 3a is selected from rigid materials. The threaded steel bar is made; the pre-embedded section of the steel rod 3 is made of steel cables in flexible materials, and the steel cable and the exposed section 6 of the prestressed steel rod 3a pass through the free section of the pre-embedded section of the steel rod 3 at a distance of 150mm from the supporting plate 5 Connection and fixation by means of welding or buckling; the construction process is: drilling holes in reinforcement object 1 or reserving installation positions → installing steel rod 3 → anchoring at the bottom of steel rod 3 → welding or Buckle → tension lock → anti-corrosion prot...

Embodiment B

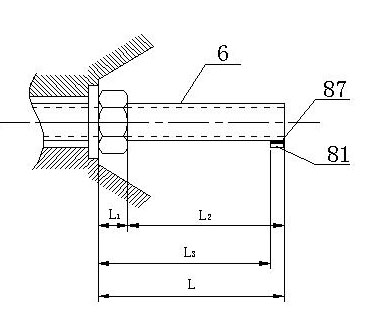

[0042] ①The process of transforming the steel rod 3 into the prestressed steel rod 3a is completed after the construction operation. According to the requirements, the length L of the exposed section 6 of the prestressed steel rod 3a should be greater than 4 times the diameter of the prestressed steel rod 3a, that is, the bottom surface of the nut 5 to the The length of the top end surface of the exposed section 6 of the prestressed steel rod 3a; the prestressed steel rod 3a generally uses a diameter of The precision-rolled threaded steel bar, the supporting nut 5 is 52mm in height, the shape is hexagonal, the distance across the sides is 48mm, and the exposed section of the prestressed steel rod 3a is 6 long L 2 Equal to 152mm, that is, the length L from the bottom surface of the nut 5 to the inner edge of the acceleration sensor 81 2 Equal to 152mm.

[0043] ② The top of the exposed section 6 of the prestressed steel rod 3a is fixedly connected with an acceleration sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com