Thread cutting device for sewing machine

A sewing machine and thread cutting technology, which is applied to sewing machine components, thread cutting mechanisms in sewing machines, sewing equipment, etc., can solve the problems of increasing the number of parts and reducing the working efficiency, and prevent the increase of the number of parts, the prevention of separation, and the prevention of operation. The effect of reducing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

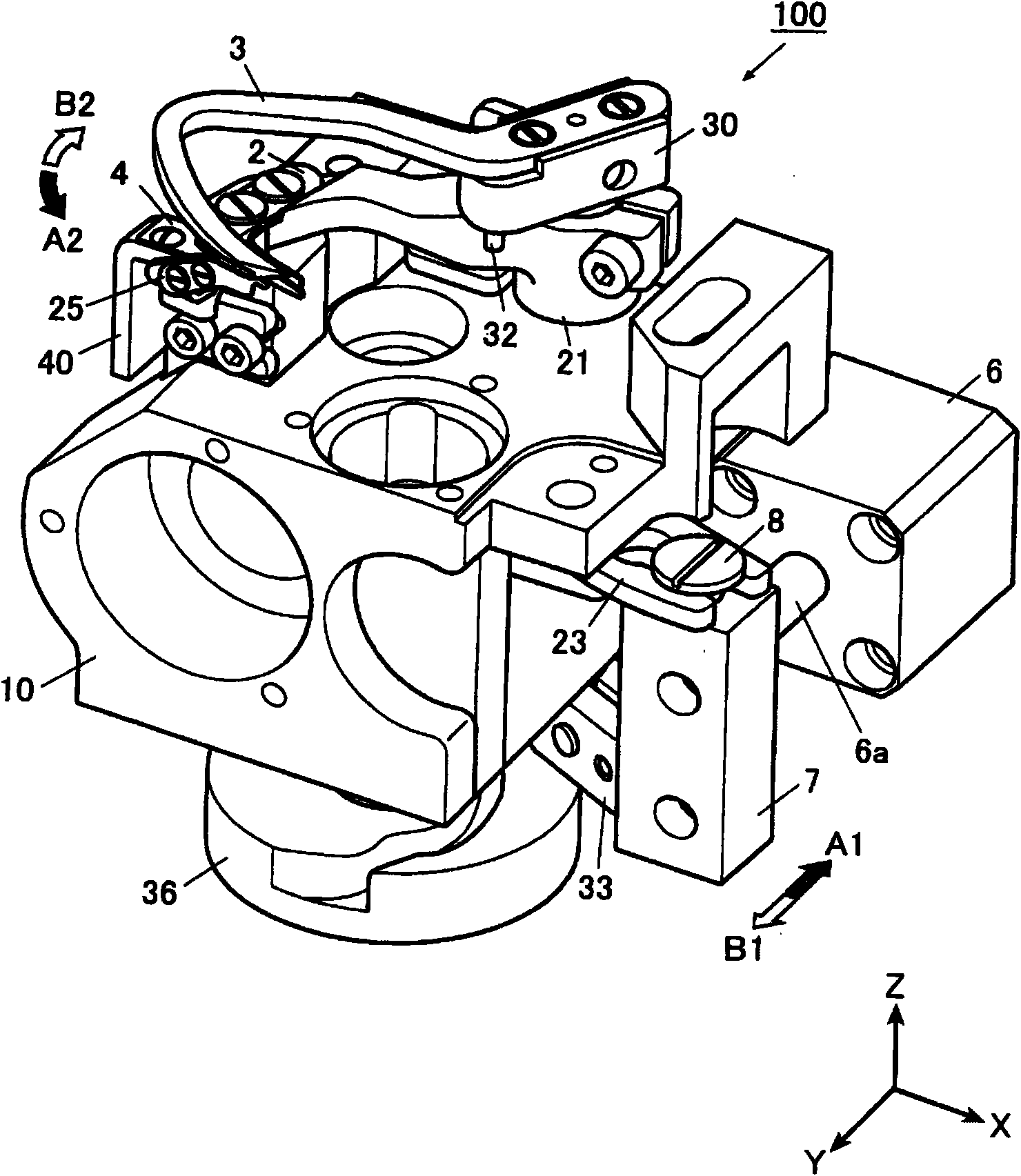

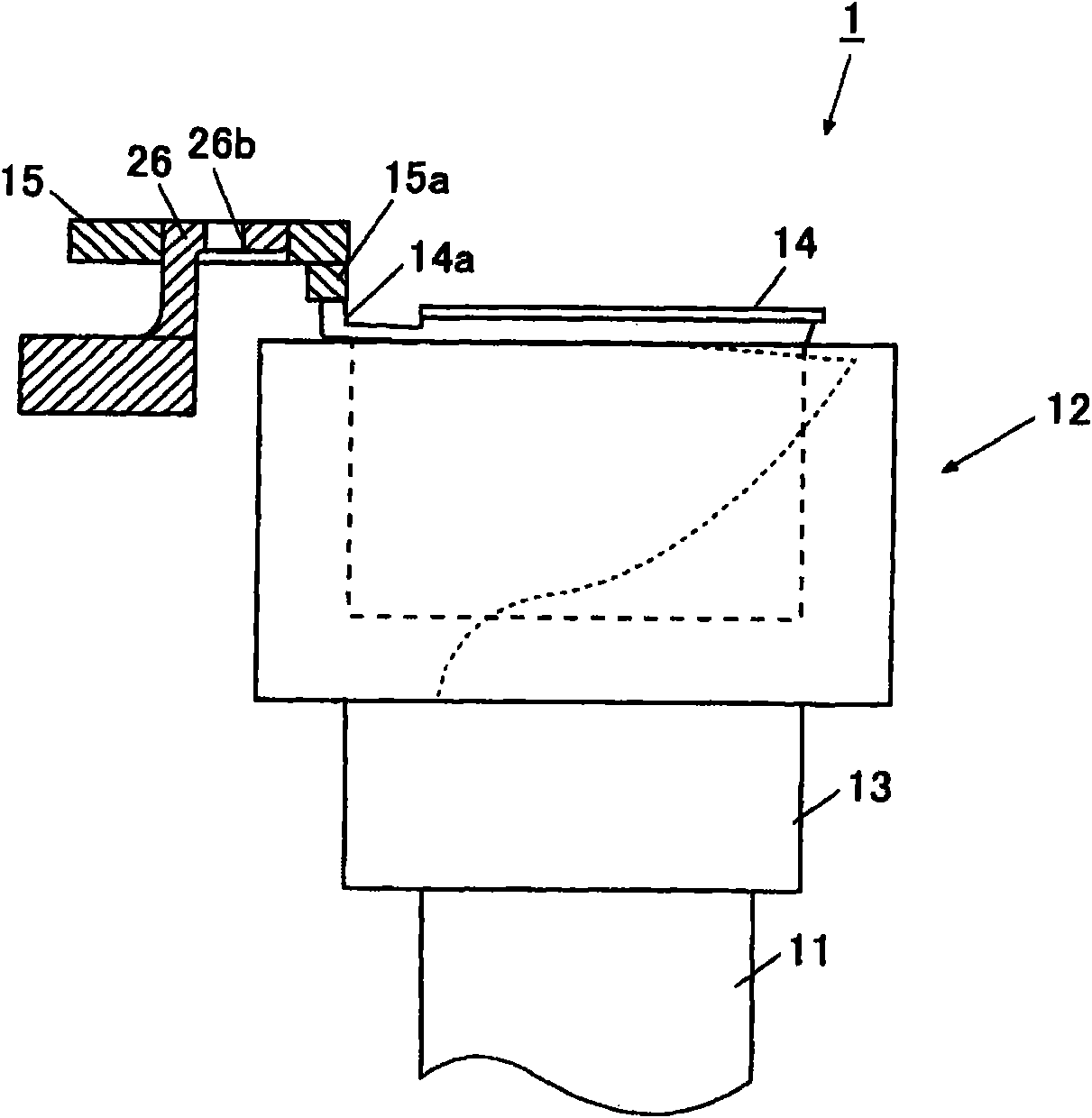

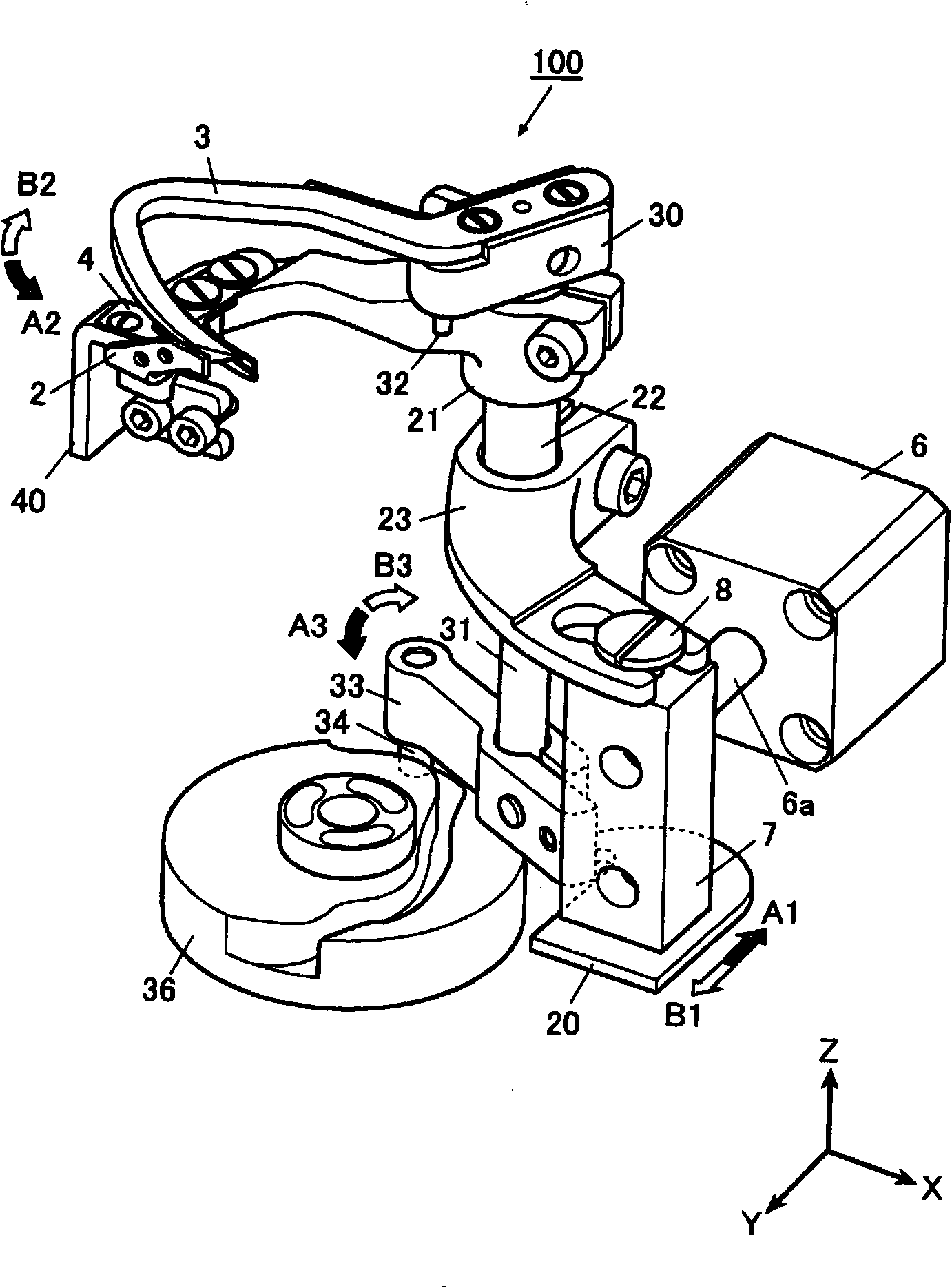

[0041] Next, embodiments of the sewing machine according to the present invention will be described in detail using the drawings.

[0042]

[0043] In this embodiment, a combined feed sewing machine will be described as an example as a sewing machine. Combined feed sewing machine (hereinafter referred to as sewing machine), in order to prevent, for example, the deviation of the sewing object accompanying the feed action, by synchronizing the needle feed action with the feed action of the upper feed mechanism and the lower feed mechanism, thereby Feed in a state where the needle is pierced through a thicker object to be sewn (such as leather), wherein the needle feeding action is to synchronize the needle up and down movement of the needle up and down movement mechanism and the needle swing of the needle swing mechanism And carried out.

[0044] The sewing machine has: an unillustrated sewing machine frame as a frame; an unillustrated sewing needle driving mechanism, which a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com