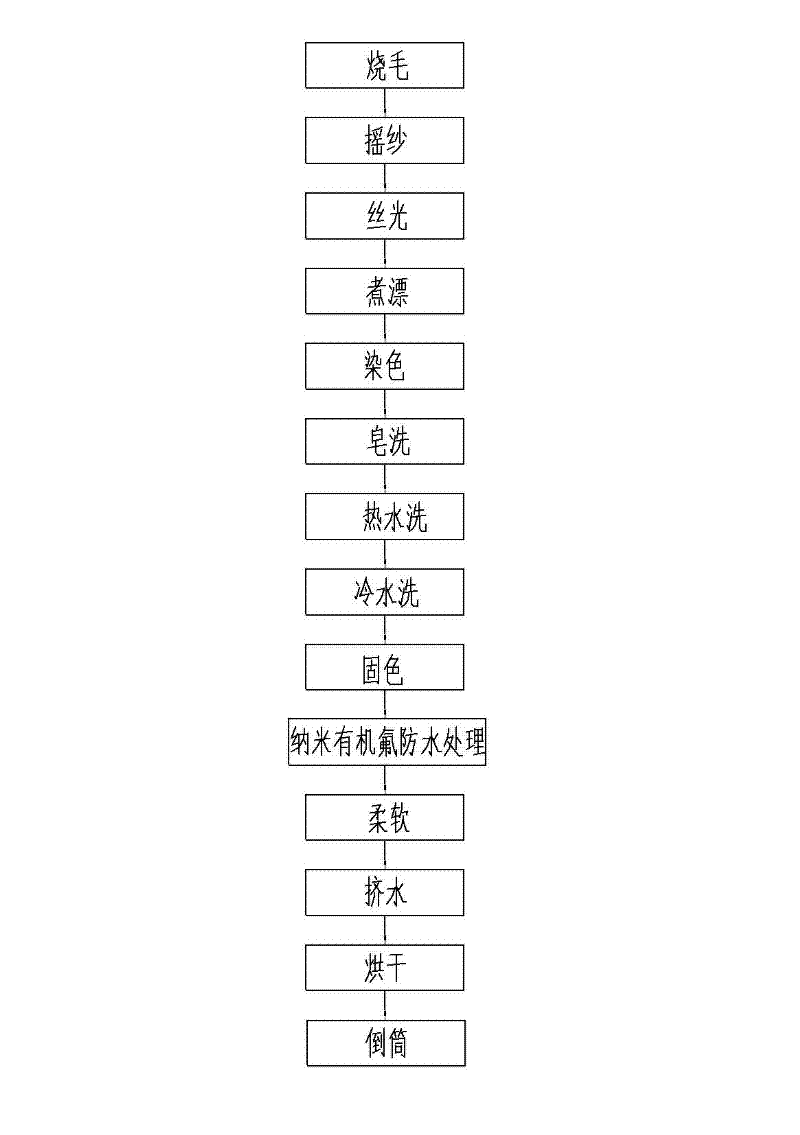

Production method of nanometer waterproof mercerized yarns

A production method and mercerizing technology, applied in yarn, textile and papermaking, fiber processing and other directions, can solve the problems of high energy consumption, complex method, long process, etc., and achieve the effect of saving processing time, simplifying processing technology and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0039] A kind of processing method of 60S / 2 waterproof mercerized cotton yarn:

[0040] 1. singeing

[0041] When singeing on the yarn singeing machine, the singeing temperature is 950°C, and the running speed of the 60S / 2 cotton yarn at the burner is 875 rpm to burn off the hairiness on the surface of the cotton yarn. The burner temperature is required to be uniform and the singeing is clean basically the same degree;

[0042] 2. Shaking yarn

[0043] On the yarn reeling machine, the package yarn after singeing is swayed into a skein shape, and the skein weight is 250g / skein;

[0044] 3. Mercerized

[0045] In the mercerizing machine, by controlling the mercerizing alkali temperature, time, tension, and alkali concentration, the yarn is evenly mercerized. The alkali concentration in the treatment solution is: 30 degrees Baume, the treatment solution temperature: 18°C, and the treatment time: 6 minutes. Tension: Stretch 3%, Washing temperature: 70°C;

[0046] 4. Boil ...

specific Embodiment 2

[0068] A kind of processing method of 70S / 2 waterproof mercerized cotton yarn:

[0069] 1. Singeing

[0070] When singeing on the yarn singeing machine, the singeing temperature is 1000°C, and the running speed of the 70S / 2 cotton yarn at the burner is 900 rpm to burn off the hairiness on the cotton yarn surface. It is required that the temperature of the burner is uniform, and the cleanliness of the singeing is basically the same;

[0071] 2. Shaking yarn

[0072] On the spinning machine, the singed cheese is shaken into a skein shape, and the skein weight is 500g / skein;

[0073] 3. Mercerized

[0074] In the mercerizing machine, by controlling the mercerizing alkali temperature, time, tension, and alkali concentration, the yarn is evenly mercerized. The alkali concentration in the treatment solution is: 28 degrees Baume, the treatment solution temperature: 20°C, and the treatment time: 6 minutes 30 seconds, tension: stretch 6%, washing temperature: 70°C;

[0075] 4. B...

specific Embodiment 3

[0097] A kind of processing method of 80S / 2 waterproof mercerized cotton yarn:

[0098] 1. Singeing

[0099] When singeing on the yarn singeing machine, the singeing temperature is 1050°C, and the running speed of the 80S / 2 cotton yarn at the burner is 1000 rpm to burn off the hairiness on the cotton yarn surface. It is required that the temperature of the burner is uniform, and the cleanliness of the singeing is basically the same;

[0100] 2. Shaking yarn

[0101] On the spinning machine, the singed cheese is swayed into a skein shape, and the skein weight is 1000g / skein;

[0102] 3. Mercerized

[0103] In the mercerizing machine, by controlling the mercerizing alkali temperature, time, tension, and alkali concentration, the uniform mercerizing of the yarn is ensured. The alkali concentration in the treatment solution is: 25 degrees Baume, the treatment solution temperature: 22°C, and the treatment time: 7 minutes. Tension: Stretch 1%, Washing temperature: 70°C;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com