Method for washing hydrophobic membrane for treating industrial wastewater

A technology of industrial wastewater and hydrophobic membrane, applied in osmosis/dialysis water/sewage treatment, chemical instruments and methods, membrane technology, etc., can solve the problems of unsatisfactory mass transfer rate recovery effect, etc., to achieve reuse and restore hydrophobicity , Improve the effect of membrane hole blocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

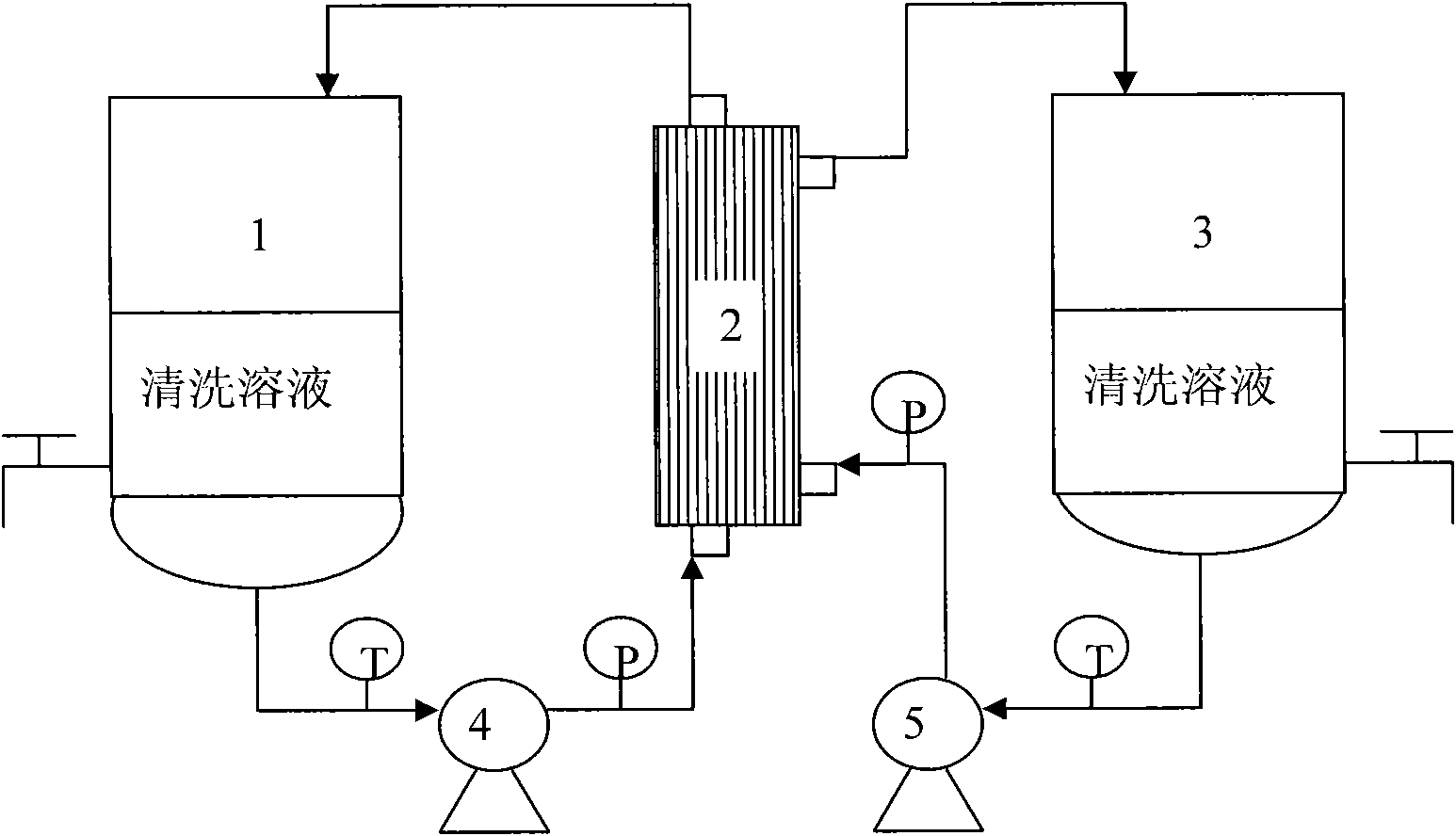

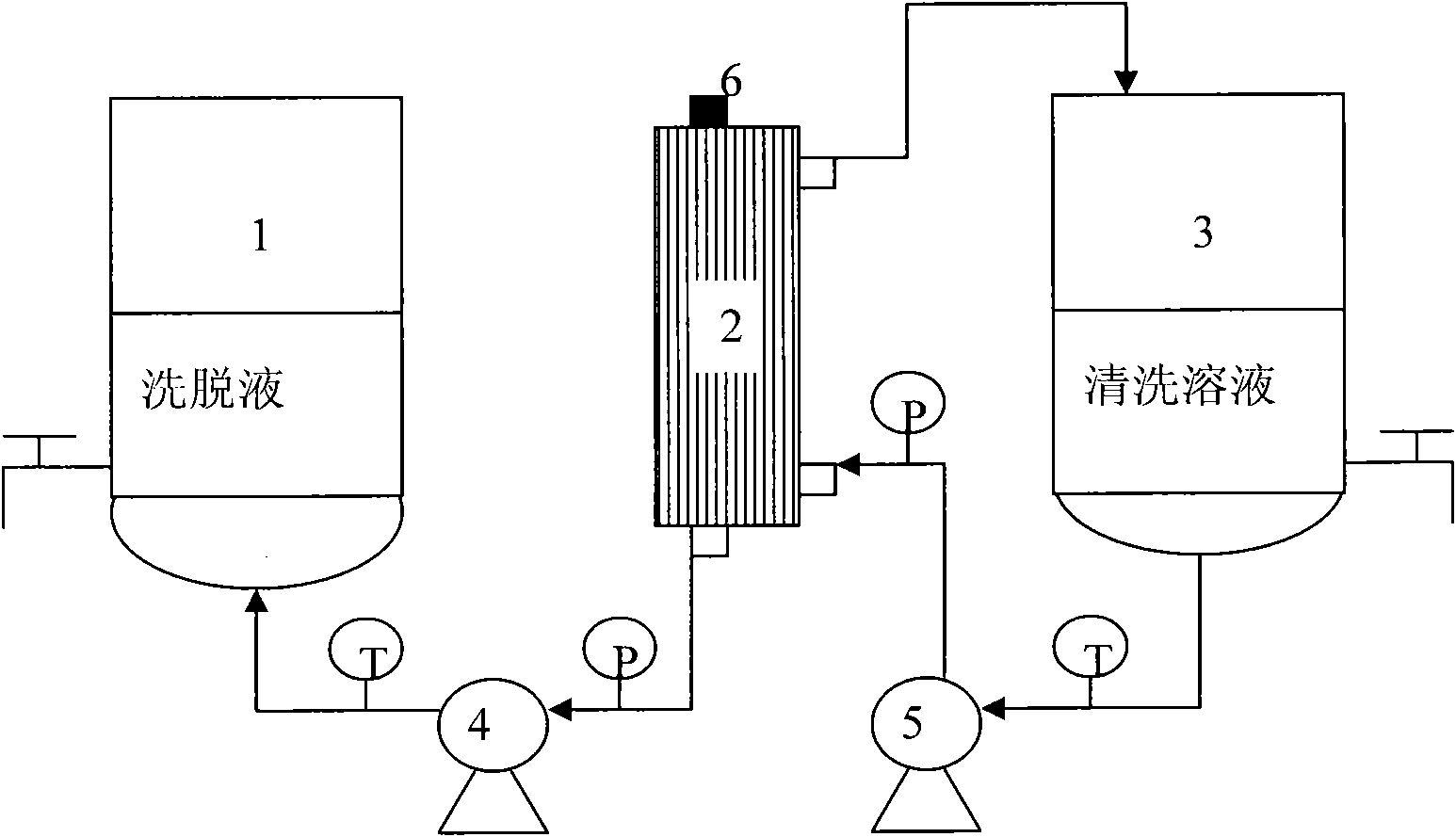

[0024] Use NaOH solution, HCl solution, EDTA solution and air to clean the membrane in the membrane module in sequence. Circulation and membrane suction are carried out in four ways, among which,

[0025] Soaking and cleaning: put the inner and outer surfaces of the membrane in the membrane module in full contact with the cleaning solution and let it stand for more than 1 hour; tube-side circulation: make the cleaning solution form a tangential flow on the inner surface of the membrane wire (or the surface of one side of the membrane), which can be realized by a circulating pump The tube-side circulation flow inside the membrane filament is realized, and the cleaning time is more than 20 minutes; the shell-side circulation: the cleaning solution forms a tangential flow on the outer surface of the membrane filament (or the surface of the other side of the membrane), and a circulation pump can be used to realize the external cleaning of the membrane filament. The shell-side circ...

Embodiment 1

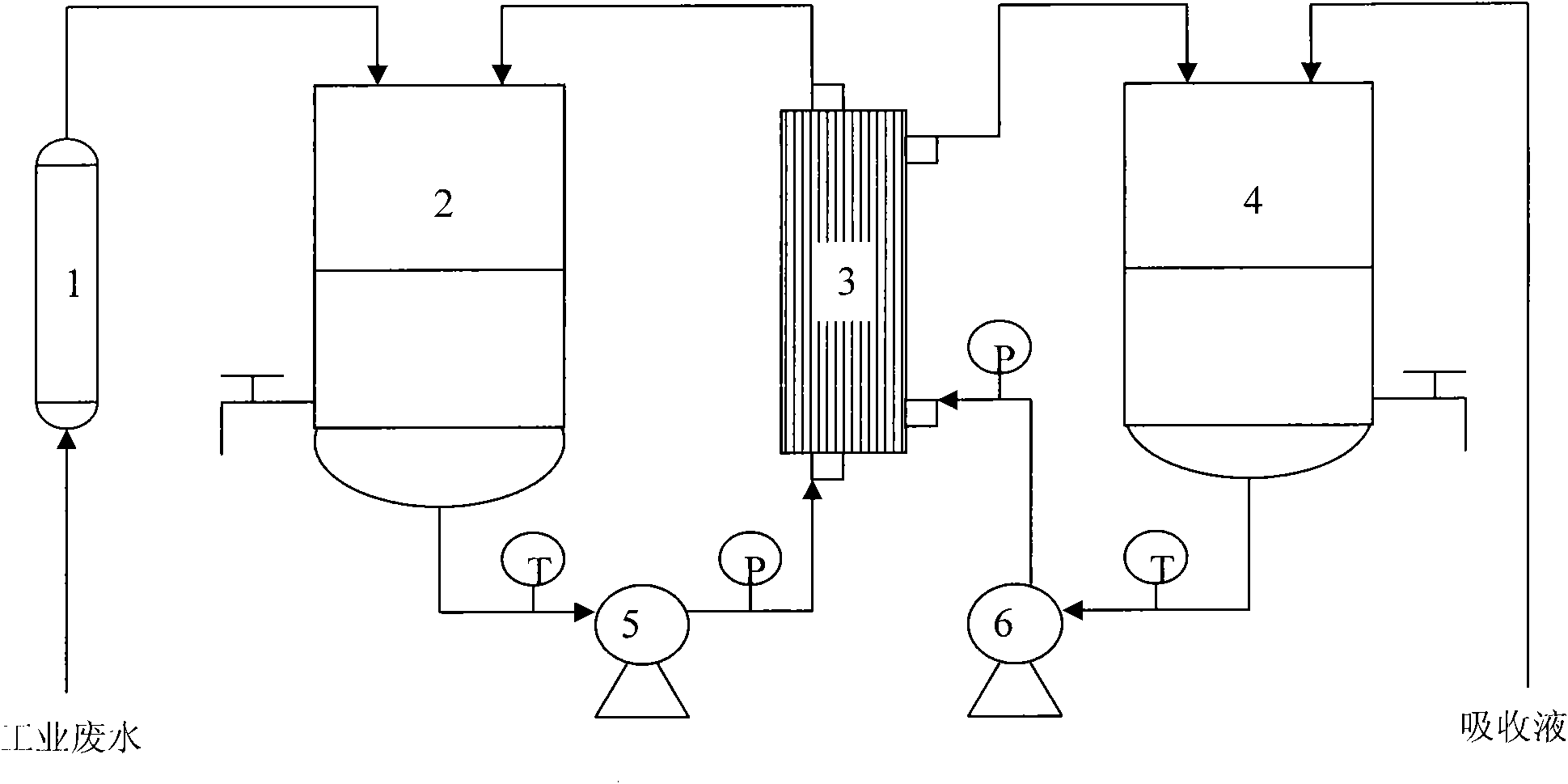

[0028] figure 1Represent the liquid / liquid membrane (hollow fiber) absorption system that is used to reclaim the cyanide in the acrylonitrile production waste water of embodiment one, this device system is mainly by microfiltration device 1, waste water circulation pool 2, membrane module 3, absorption liquid circulation Pool 4, waste water (pipe side) circulation pump 5, absorption liquid (shell side) circulation pump 6 and other components. The cyanide in the acrylonitrile wastewater is acidified to produce hydrocyanic acid (circulation in the tube side) which is absorbed by the alkaline absorption solution in the membrane module (circulation in the shell side). The mass transfer coefficient k of cyanide from the tube side to the shell side continues to decrease with the membrane absorption process, which indicates the occurrence of membrane fouling (such as Figure 4 ). When k continues to decrease and the cyanide concentration in the acrylonitrile wastewater remains subs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com