Direct magnetic suspension permanent magnet linear synchronous motor for numerical control feeding platform

A magnetic levitation and motor technology, applied in the field of motors, can solve problems such as poor effect, poor stability and reliability, and complex structure, and achieve the effect of easy adjustment, simple magnetic circuit structure, and difficult adjustment of the air gap magnetic field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing, the present invention will be further described:

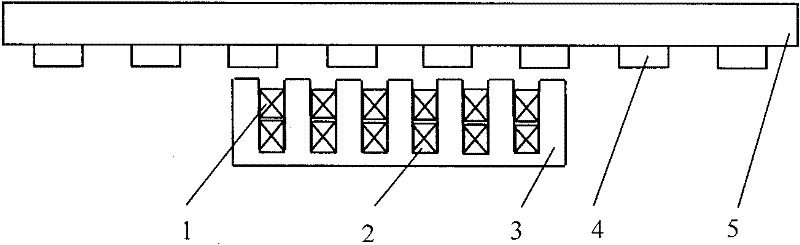

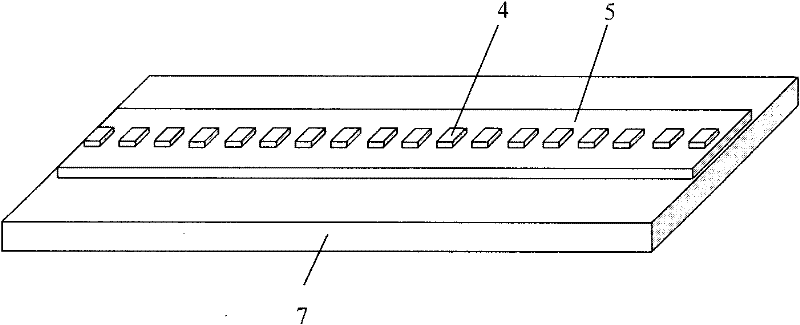

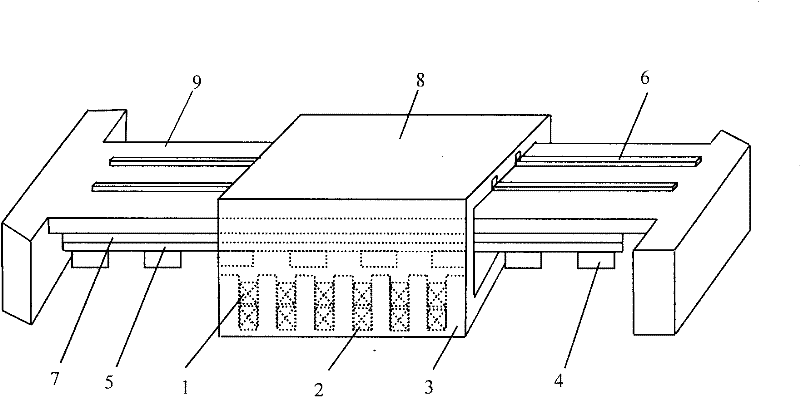

[0024] Such as figure 1 and 2 As shown, the present invention provides a direct magnetic levitation permanent magnet linear synchronous motor for a digitally controlled feed platform, comprising a stator core 5 and a mover core 3 that moves along the stator core 5 during use, and the stator core 5 is arranged on a non-magnetic on the motor base 7. The permanent magnet 4 is arranged on the side of the stator core 5 facing the mover core 3 .

[0025] Two sets of electrically independent windings are arranged in the mover core 3, one of which is the thrust winding 2 for generating electromagnetic thrust, and the other is the levitation winding 1 for adjusting the magnetic levitation force; the thrust winding 2 When in use, the mover core 3 can move relative to the stator core 5, and the suspension winding 1 can make the mover core 3 suspend under the stator core 5, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com