Three-phase AC asynchronous motor for YDAX series of electric automobiles

An asynchronous motor and electric vehicle technology, applied in the field of electric motors, can solve the problems of increasing the technical difficulty of design and development and the cost of design and development, and achieve the effects of good working conditions, safe and reliable operation, and low noise.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

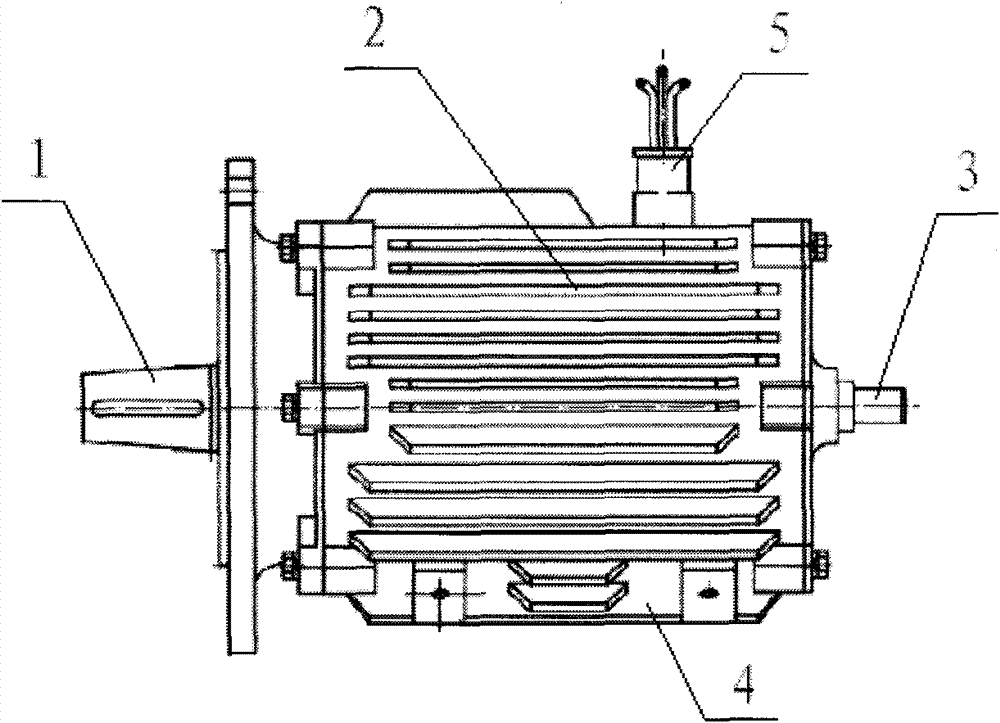

[0022] Such as figure 1 The shown three-phase AC asynchronous motor for YDAX series electric vehicles has a casing 4, a stator and a rotor. The casing 4 is a cast aluminum alloy casing made by an extrusion die process, which satisfies the classification of the extrusion die of the machine base. Require. The slenderness ratio of the motor is 1.3-6.0. Because the motor is slender, the moment of inertia and peripheral speed of the rotor are small, but it is beneficial to the motor with a higher speed. The rated frequency of the motor for electric vehicles is generally 80-200Hz, so The volume of the motor with the same capacity is much smaller than that of ordinary motors when it is designed, which is only equivalent to 1 / 2 to 1 / 3 of the motor with the same specification. Radiating fins 2 on the casing are vertically and evenly distributed around the circumference of the machine base, and outlets 5 are located at the rear end of the machine base. The six straps evenly distribute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com