Quantum cascade laser with photonic quasi-crystal waveguide and manufacture method thereof

A quasi-photonic crystal and quantum cascade technology, which is applied in semiconductor lasers, lasers, phonon exciters, etc., can solve problems affecting the application of quantum cascade lasers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In the following, the present invention will be further described by taking the InP / InGaAs / InAlAs material system and quantum cascade laser with weakly disordered quasi-photonic crystal waveguide as an example, but this does not constitute a limitation to the present invention.

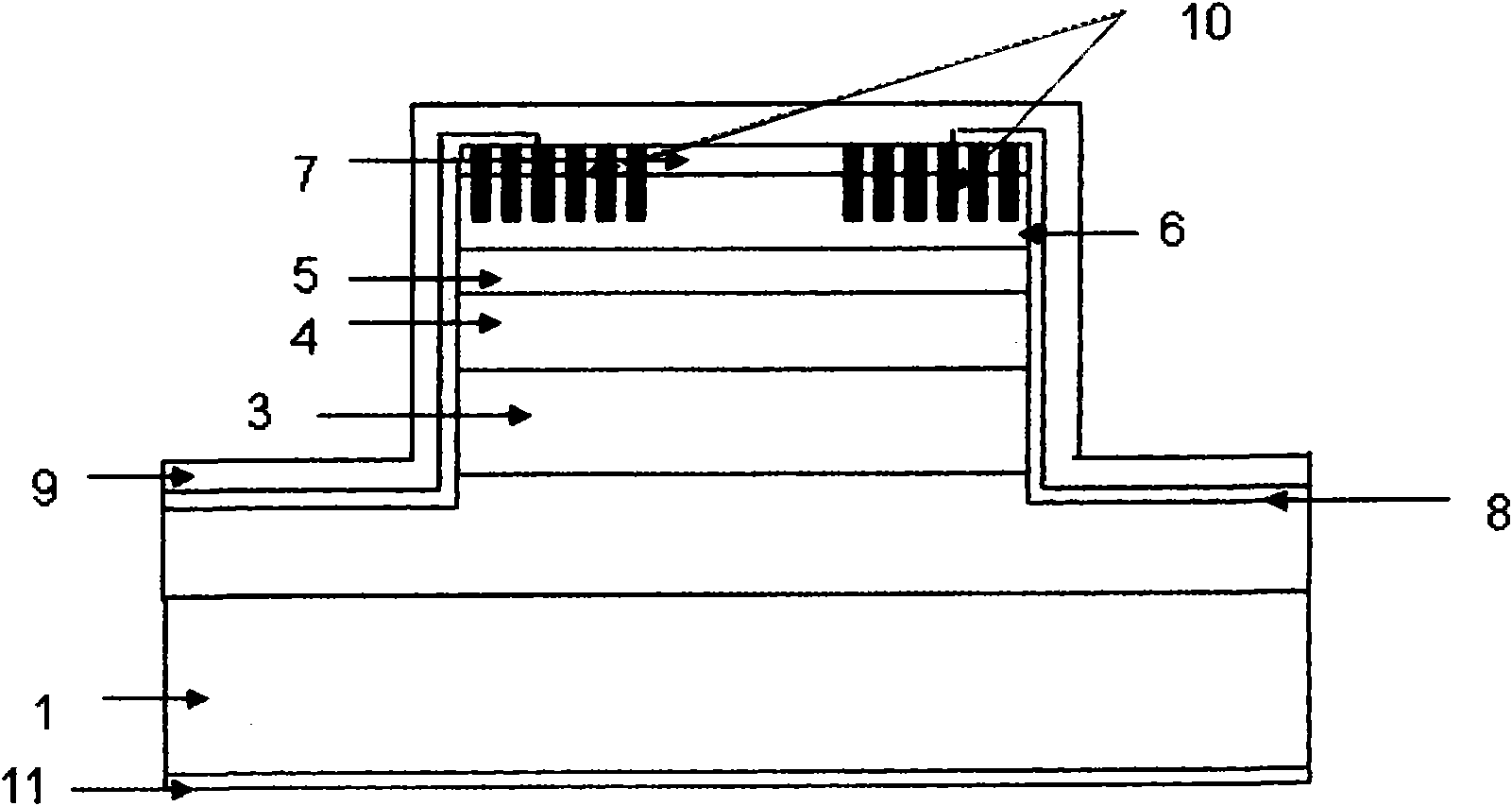

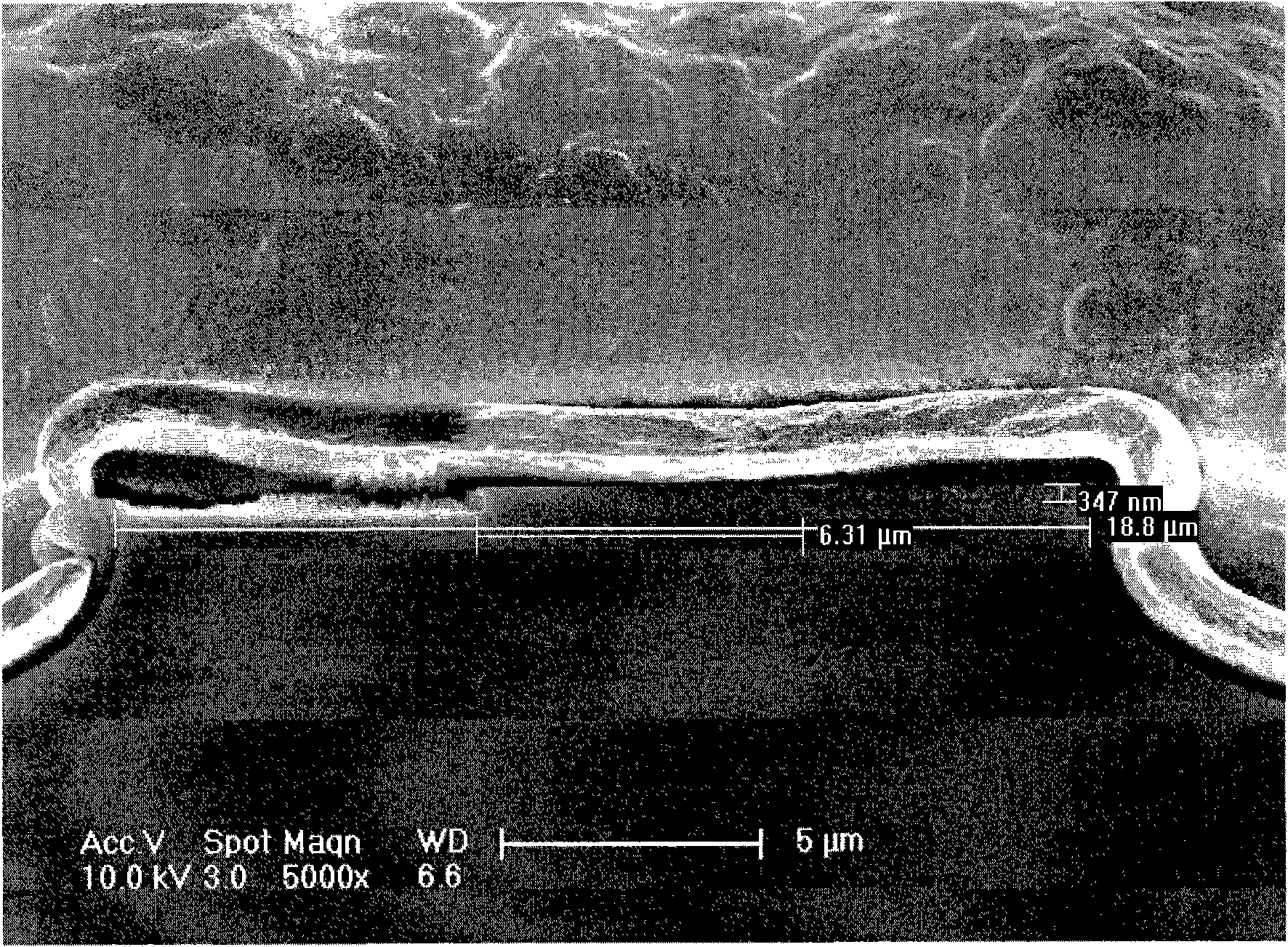

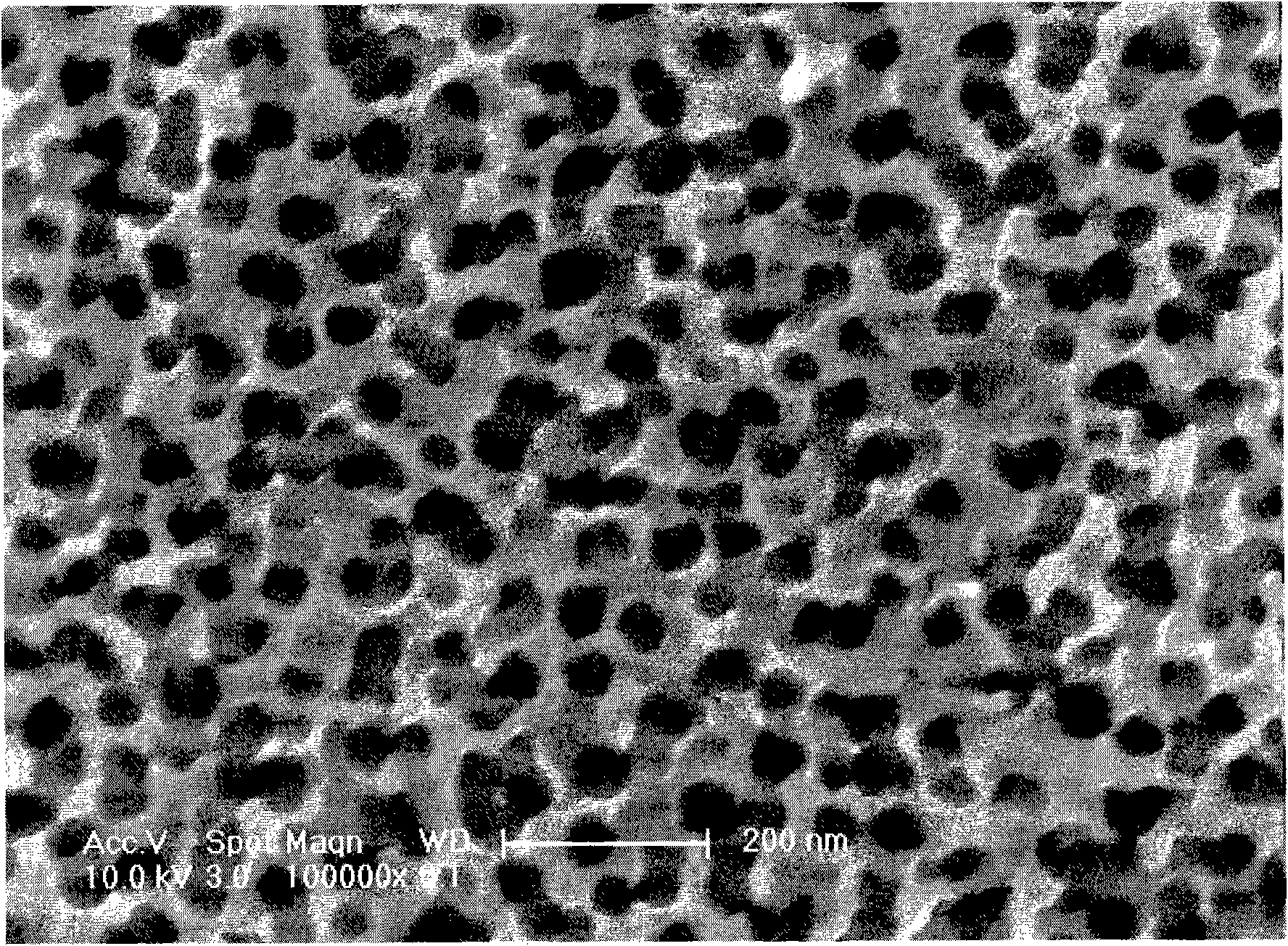

[0044] The invention provides a quantum cascade laser structure with a weakly disordered quasi-photonic crystal waveguide structure, including an n-type doped InP substrate, an InGaAs lower waveguide layer, a 35-level periodic quantum cascade active region structure, and an InGaAs upper Waveguide layer, InP upper cladding layer, InP upper cladding layer, highly doped InP ohmic contact layer, quasi-photonic crystal waveguide, double-groove-ridge structure. See the specific structure figure 1 Shown is a schematic cross-sectional structure diagram of the present invention, including:

[0045] A substrate 1; the substrate is an n-type doped InP substrate with a doping concentration of 1-3×10 17 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com