Visual detection method for quality of liquid medicine on high-speed pharmaceutical production line

A visual inspection and production line technology, applied in color/spectral characteristic measurement, image data processing, instruments, etc., can solve problems such as small quantity, small individual, no texture information, etc., achieve fast detection and recognition speed, guarantee speed requirements, The effect of ensuring the detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

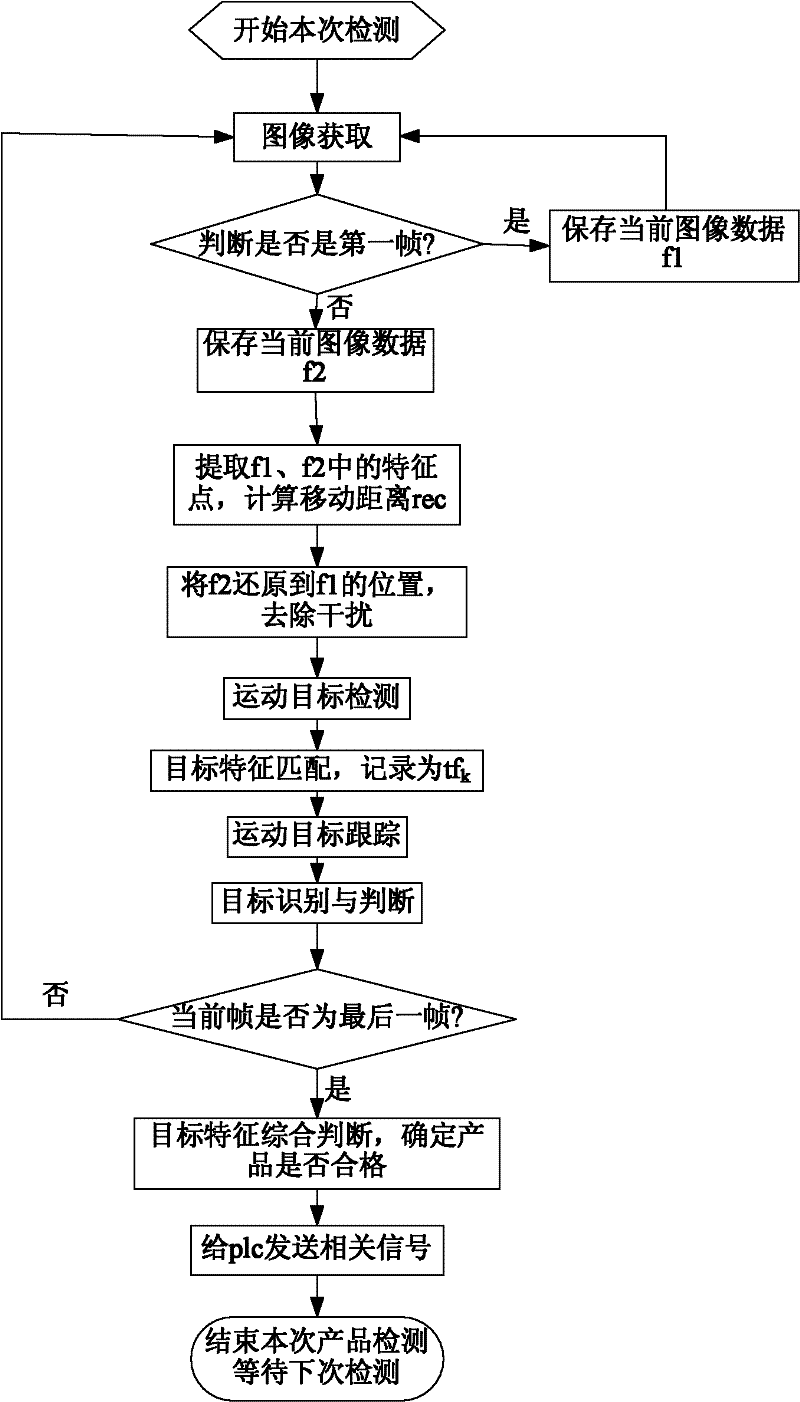

[0060] The steps in this example are as follows:

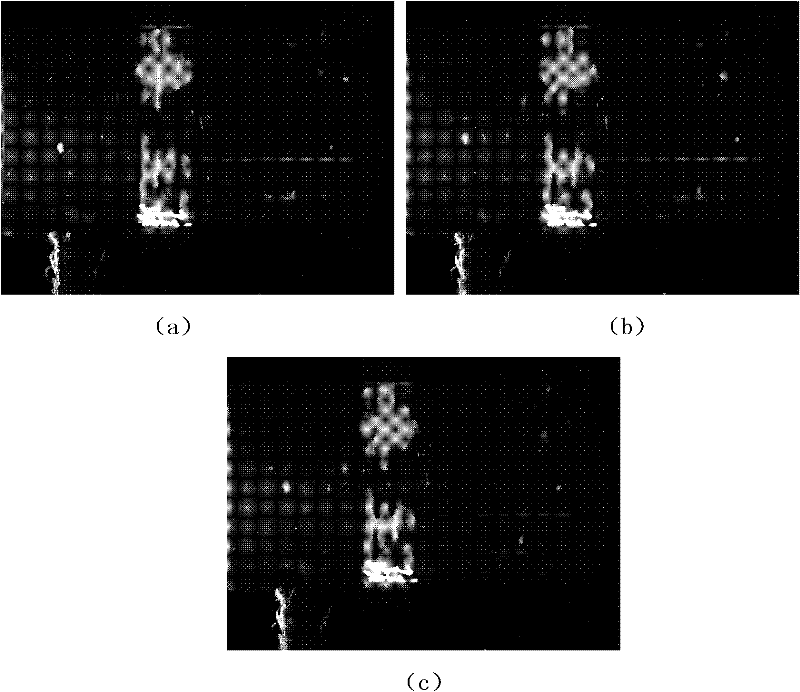

[0061] (1) Image acquisition: Acquire 5 consecutive images of the pre-rotated medicinal liquid in the bottle stop state, and the time interval between each two images is about 10ms. This time interval can ensure that the speed of the production line is met. There will be no overlapping of foreign matter images between two consecutive images, and the moving distance of foreign matter will not be too large, thereby further ensuring the detection accuracy of subsequent detection algorithms; at the same time, due to the requirements of production line speed, the captured images are grayscale images, Reduce the amount of processed data and processing time.

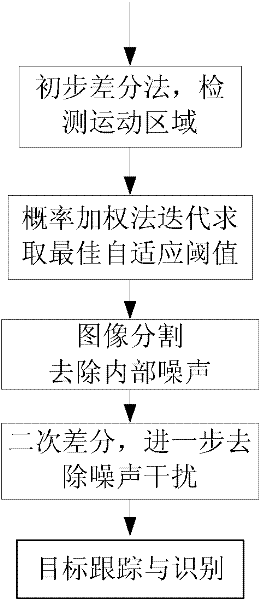

[0062] (2) Preliminary denoising of the image: due to various reasons, it is possible that the liquid medicine container, that is, the medicine bottle, is still moving when the liquid medicine is photographed, which will cause great interference to the detection. Therefore, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com