Production and installation of subsurface structure forceon light-emitting and color-sensitive

A technology of color-sensitive sensors and underground structures, applied in the measurement of the change in optical properties of materials when they are stressed, advanced technology, electrical components, etc., can solve the problem of hindering structural evaluation and post-rescue, and real-time geotechnical monitoring Interference, high requirements and other issues, to achieve strong real-time and observability, prevent malignant accidents, simple and clear monitoring expression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Below in conjunction with accompanying drawing, the present invention is described in more detail:

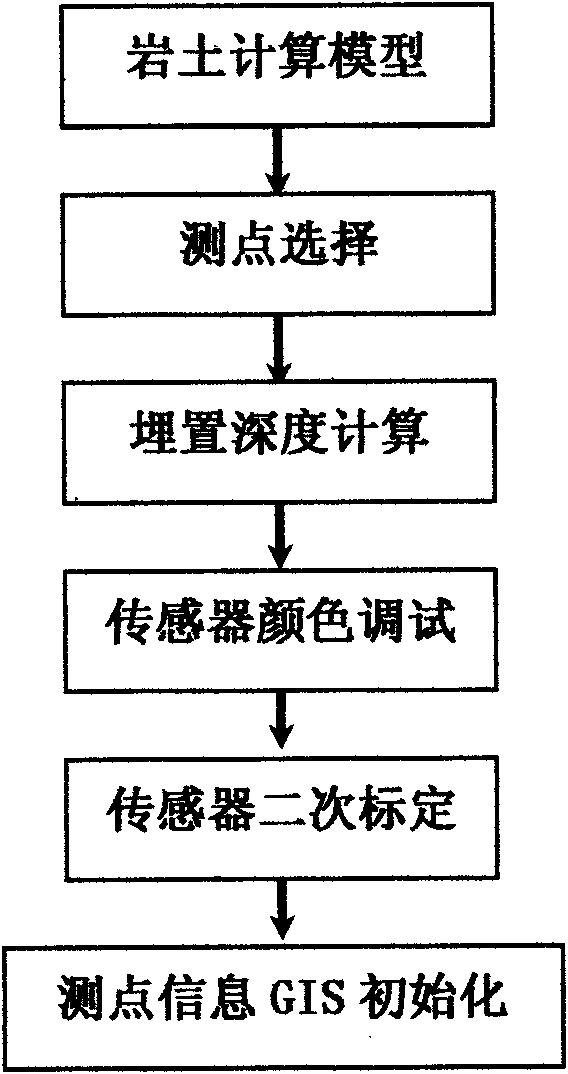

[0047] The pressure color-sensitive sensor and its monitoring system technology for real-time identification of large-scale underground structure damage status are mainly made of (A) pressure color-sensitive sensor; (B) pressure color-sensitive sensor installation process; (C) pressure color-sensitive sensor including signal transmission and post-processing The sensitive sensor monitoring system is composed of three parts, which will be described in detail below in conjunction with the accompanying drawings.

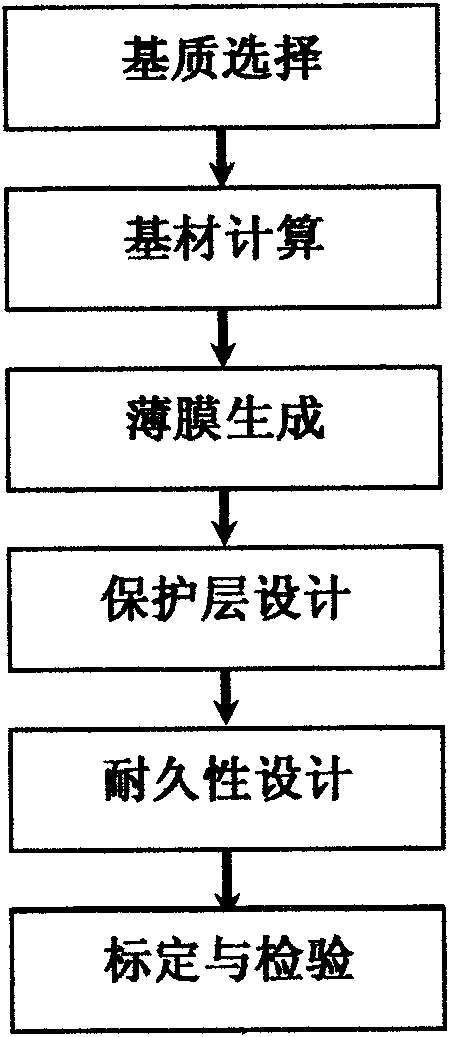

[0048] (A) Pressure color sensitive sensor and its production

[0049] 1. Pressure color sensitive sensor

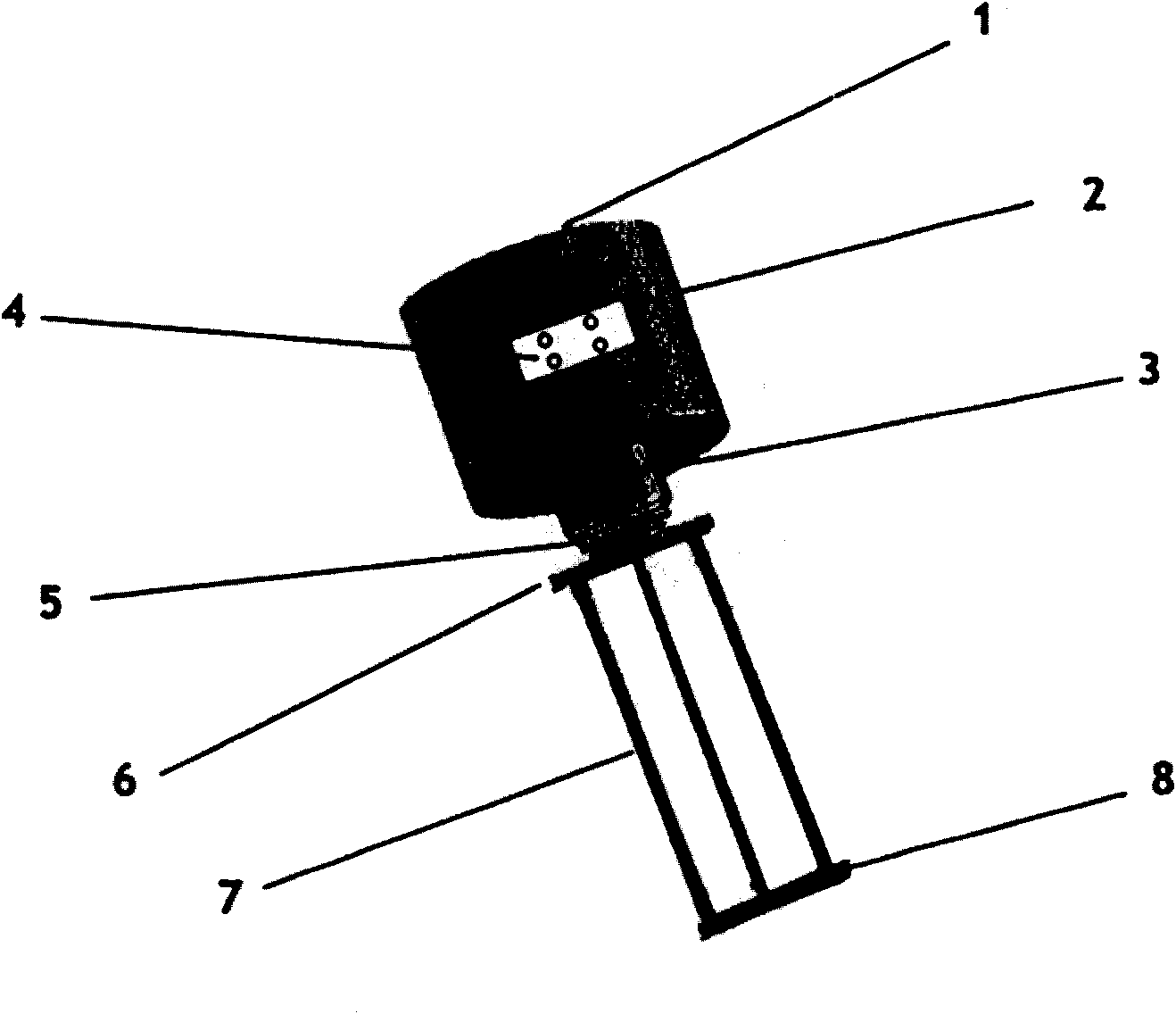

[0050] The structure of the pressure color sensitive sensor is divided into upper and lower parts, the upper part is the main structure, which is composed of a cylindrical structure and a protruding column cap at the bottom. The top 1 of the cylinder is tou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com