Energy supply system mainly through gas and steam combined cycle cogeneration

An energy supply system and combined cycle technology, applied in the energy field, can solve problems such as unreasonable energy utilization, high energy consumption for cooling transmission and distribution, high pump consumption, etc., and achieve the effect of avoiding transmission and distribution losses, reducing investment and transmission and distribution losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

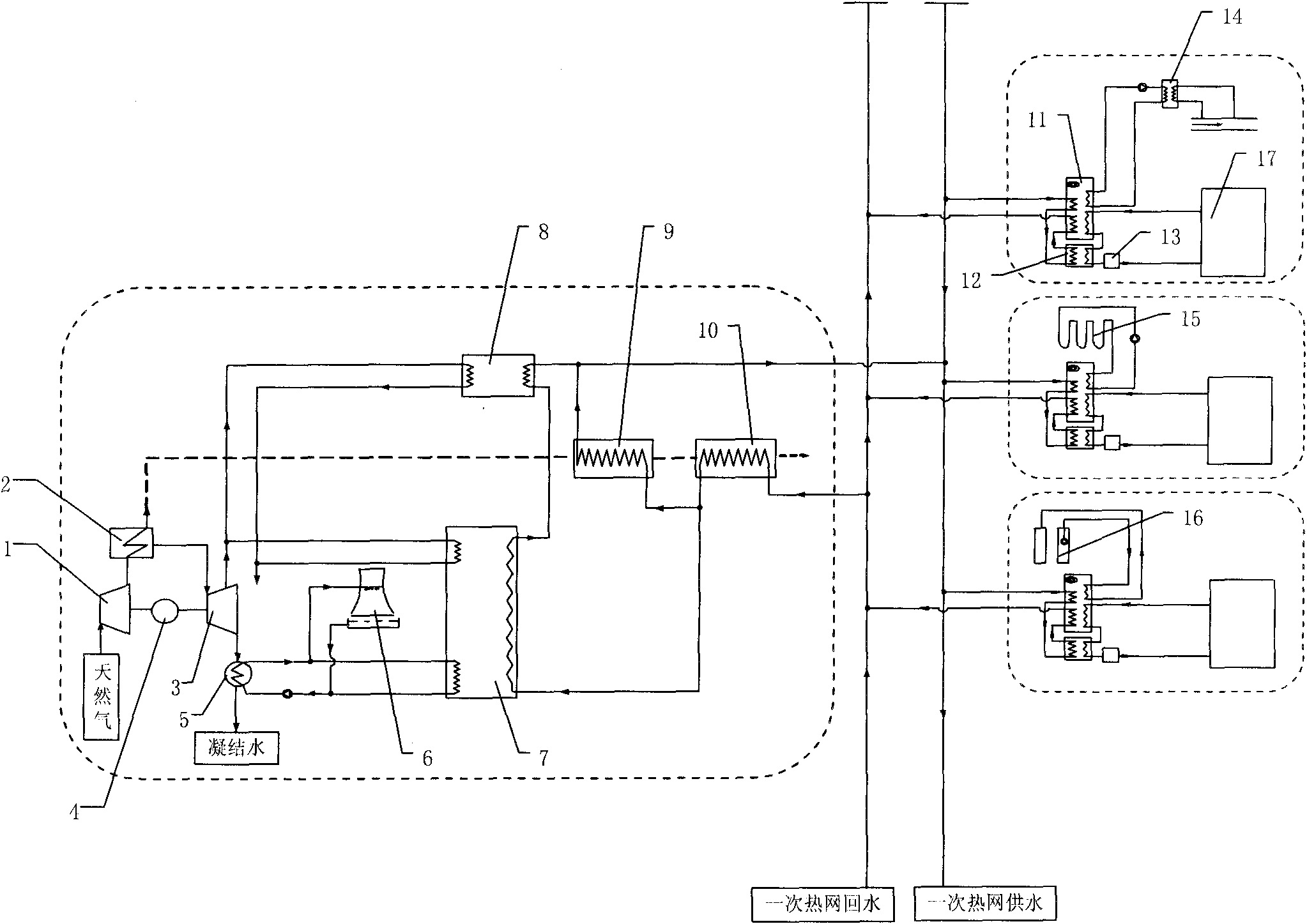

[0033] Figure 1(a) and Figure 1(b) are schematic diagrams of the basic flow charts of heating and cooling for direct recovery of waste heat from flue gas, recovery of waste heat from condensation by steam-type absorption heat pump, and parallel connection of heating side.

[0034] This energy supply mode mainly consists of gas turbine 1, waste heat boiler 2, steam turbine 3, generator 4, condenser 5, cooling tower 6, steam absorption heat pump 7, steam-water heat exchanger 8, high-temperature flue gas exchange Heater 9, flue gas condensing heat exchanger 10, supplementary combustion hot water absorption heat pump 11, water-water heat exchanger 12, gas boiler 13, solution dehumidification air conditioner 18, domestic hot water preheating heat exchanger 19, a No. underground pipe heat exchanger 15 or underground water pumping, recharge well 16 or sewage heat exchanger 14 and connecting pipelines and accessories.

[0035]Under the winter heating conditions shown in Figure 1(a), n...

Embodiment 2

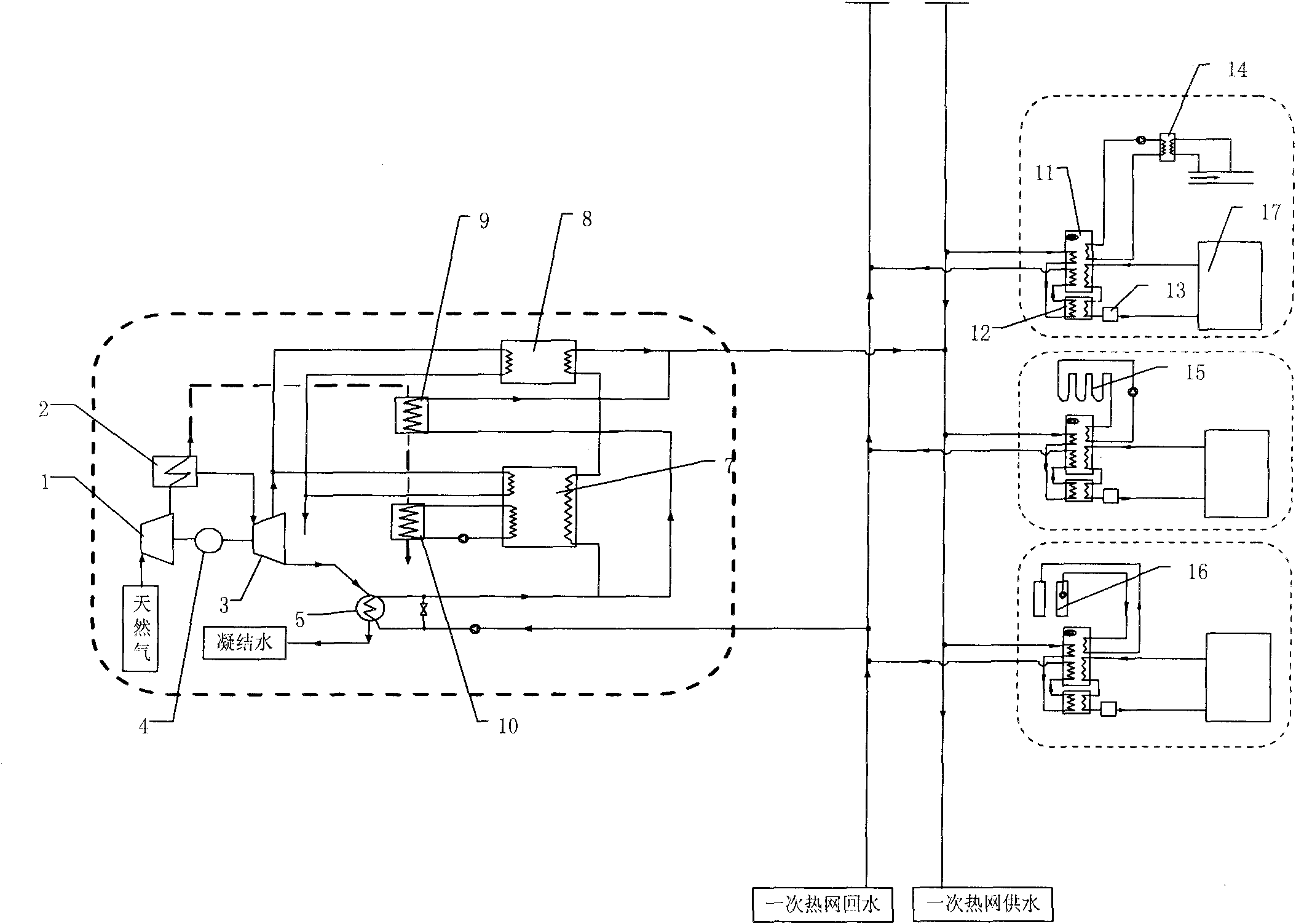

[0038] Fig. 2(a) and Fig. 2(b) are the basic flow diagrams of heating and cooling in direct recovery of condensing waste heat, recovery of low-temperature flue gas waste heat by steam-type absorption heat pump, and parallel connection of heating side, respectively.

[0039] This energy supply mode mainly consists of gas turbine 1, waste heat boiler 2, steam turbine 3, generator 4, condenser 5, steam-type absorption heat pump 7, steam-water heat exchanger 8, high-temperature flue gas heat exchanger 9, Flue gas condensing heat exchanger 10, afterburning hot water absorption heat pump 11, water-water heat exchanger 12, gas boiler 13, solution dehumidification air conditioner 18, domestic hot water preheating heat exchanger 19, No. 1 buried pipe Heat exchanger 15 or underground water pumping, recharge well 16 or sewage heat exchanger 14 and connecting pipelines and accessories.

[0040] Under the winter heating conditions shown in Figure 2(a), the return water of the primary heati...

Embodiment 3

[0043] Figure 3(a) and Figure 3(b) are schematic diagrams of the basic flow charts of heating and cooling for direct recovery of flue gas waste heat, three-stage steam-type absorption heat pump series recovery of condensate waste heat, and parallel connection of the heating side, respectively.

[0044] This energy supply mode mainly consists of gas turbine 1, waste heat boiler 2, steam turbine 3, generator 4, condenser 5, cooling tower 6, primary steam absorption heat pump 7a, secondary steam absorption heat pump 7b, three Stage steam absorption heat pump 7c, steam-water heat exchanger 8, high-temperature flue gas heat exchanger 9, flue gas condensation heat exchanger 10, supplementary combustion hot water absorption heat pump 11, water-water heat exchanger 12, Composed of gas boiler 13, solution dehumidification air conditioner 18, domestic hot water preheating heat exchanger 19, No. 1 buried pipe heat exchanger 15 or groundwater pumping, recharge well 16 or sewage heat exchan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com