A high heat and power ratio combined heat and power system and its working method

A heating system and specific heat technology, applied in preheating, energy industry, feed water heaters, etc., can solve problems such as the limitation of heat-to-electricity ratio of power generation, and achieve the effect of improving efficiency, increasing heat-to-electricity ratio, and lower investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

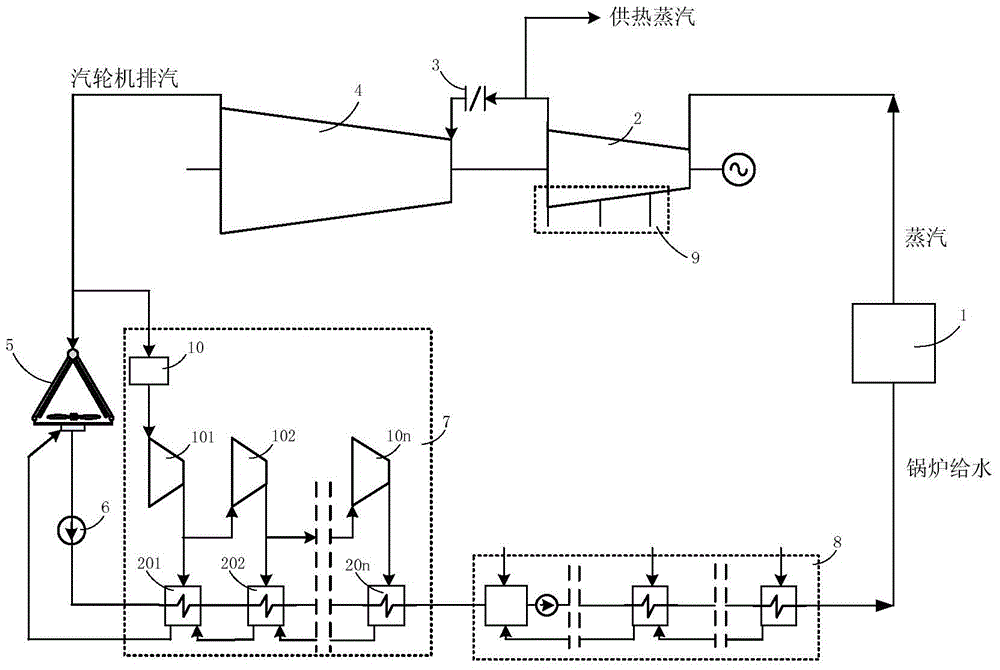

[0018] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0019] The working principle of the present invention is as follows:

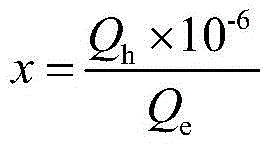

[0020] Combined heat and power generation unit refers to the production method that uses high-temperature and high-pressure steam to generate electricity, and then uses all or part of the steam that has done work to provide heat to users, which saves fuel compared to producing electricity and heat energy separately. Cogeneration of heat and power is an effective form of thermal energy utilization in grades. Adjusting the extraction steam cogeneration unit can adjust the extraction steam volume with the change of the external heat load, and the electric power can change with the electric load without being limited by the heat load. Therefore, the current large cogeneration units are steam extraction cogeneration units. However, the combined heat and power unit has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com