Pressure reducing valve having shutoff mechanism

A technology of cut-off mechanism and pressure reducing valve, which is applied in the direction of fluid pressure control, safety valve, balance valve, etc., can solve the problems of complex internal structure, large-scale product and high cost, so as to suppress the increase of cost and realize miniaturization. , the effect of preventing deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

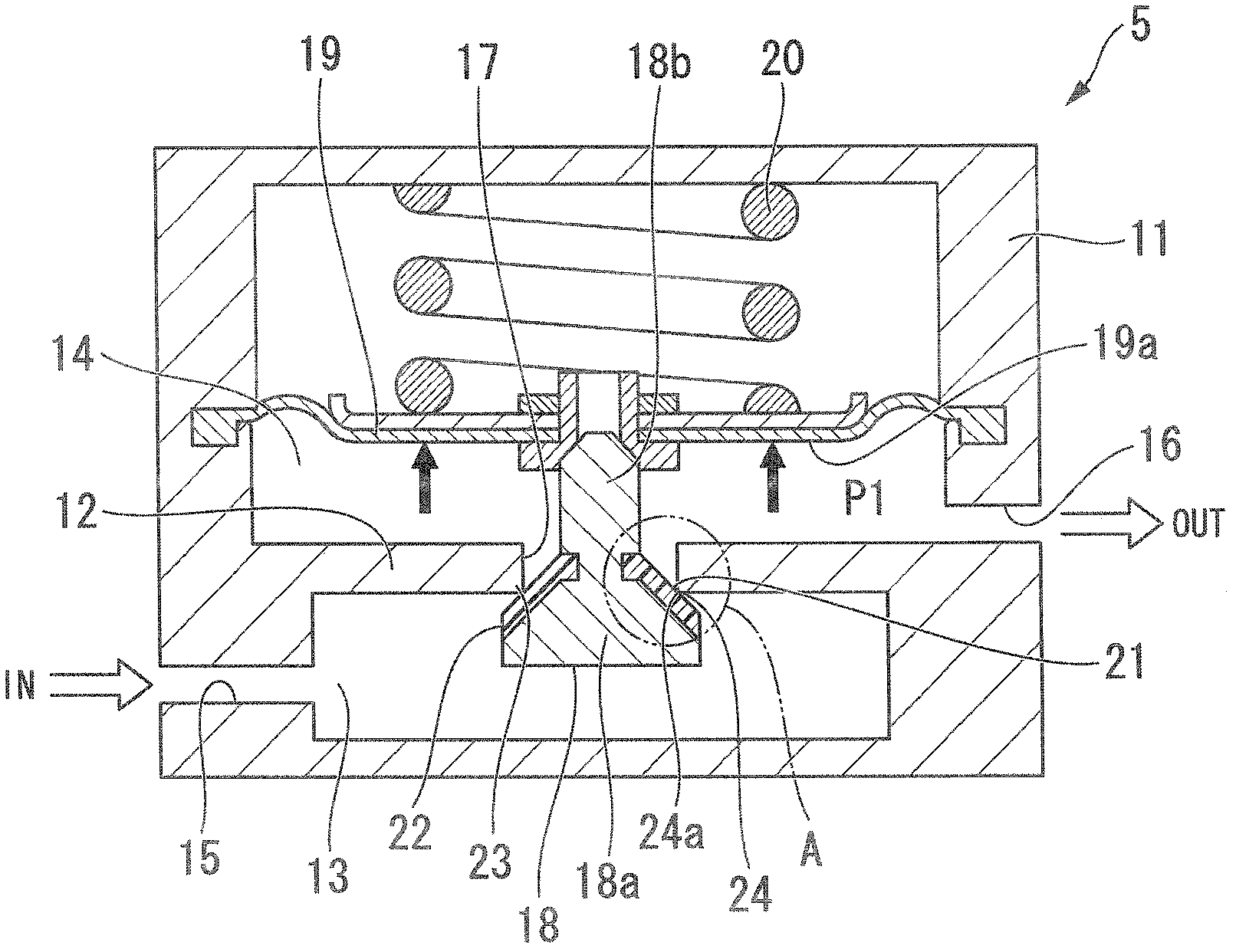

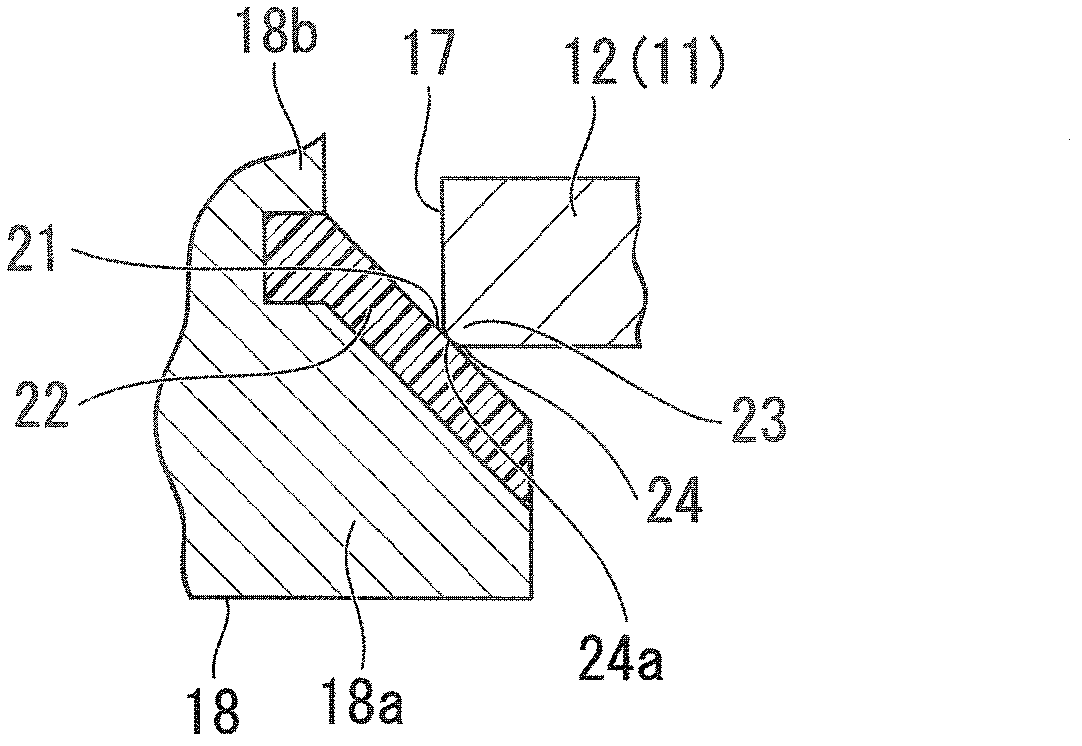

[0030] Hereinafter, an embodiment of the present invention will be described based on the drawings.

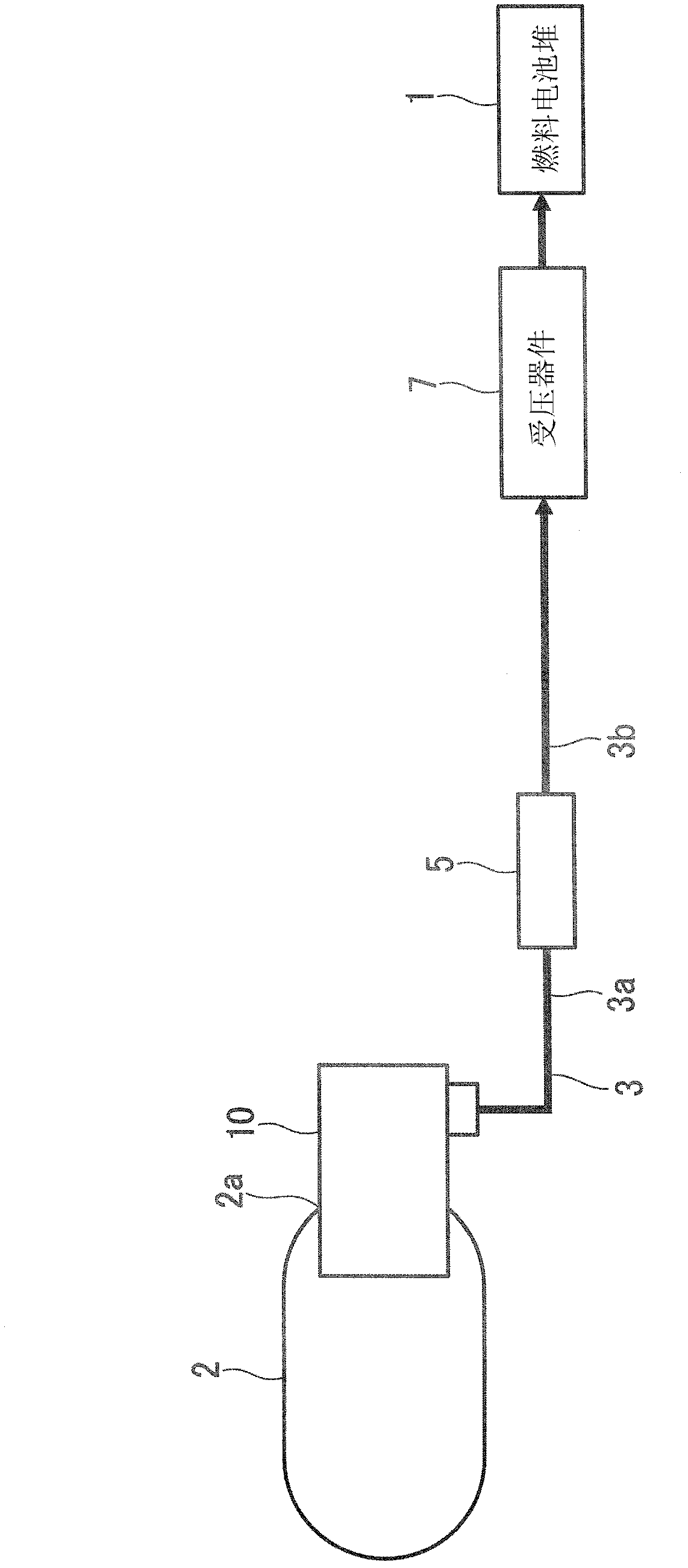

[0031] figure 1 It is a schematic configuration diagram of a fuel cell system, and reference numeral 1 denotes a fuel cell stack (fuel cell) that is supplied with hydrogen as a fuel and oxygen as an oxidant to generate electricity. The fuel cell stack 1 is, for example, a solid polymer fuel cell (Polymer Electrolyte Fuel Cell: PEFC), and is a single stack in which a MEA (Membrane Electrode Assembly, membrane electrode assembly) is sandwiched by separators (not shown). made of batteries.

[0032] Hydrogen gas at a predetermined pressure and a predetermined flow rate is supplied to the fuel cell stack 1 from a hydrogen storage tank 2 storing high-pressure hydrogen (a supply source of high-pressure fluid) through a hydrogen supply flow path 3, and at a predetermined pressure through an air supply device (not shown). Oxygen-containing air is supplied to the fuel cell stack 1 at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com