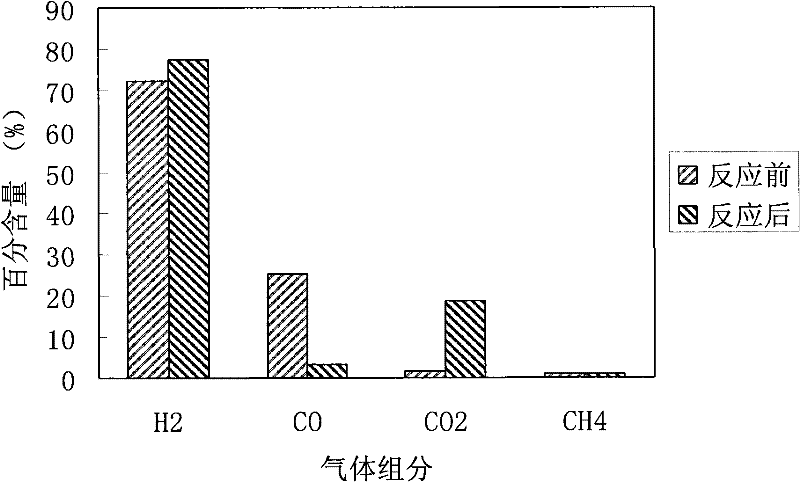

Method for preparing iron-based chrome-free high-temperature water gas conversion catalyst in hydrogen-rich atmosphere

A technology for transforming catalysts and hydrogen-rich atmospheres, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc. Sintering and other problems, to achieve the effect of wide activation temperature, good thermal stability and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

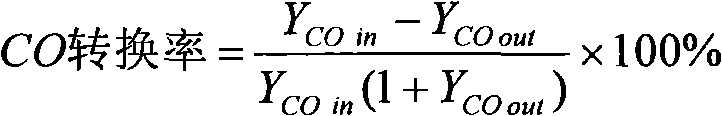

Examples

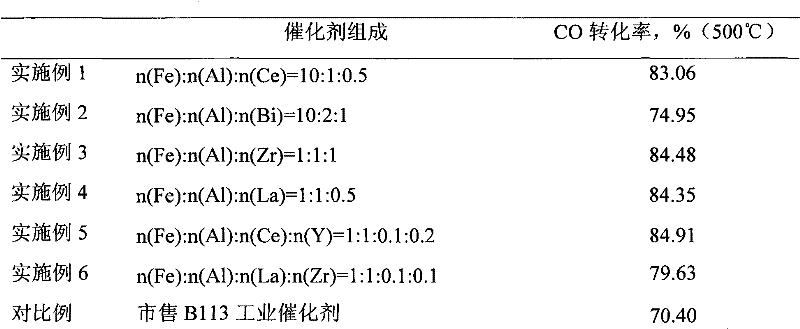

Embodiment 1

[0017] Embodiment 1: According to molar ratio n(Fe):n(Al):n(Ce)=10:1:0.5, weigh 50.6g Fe(NO 3 ) 3 9H 2 O, 4.7gAl(NO 3 ) 3 9H 2 O and 2.7g Ce(NO 3 ) 3 ·6H 2 O, dissolved in 550 mL deionized water. At the same time, 20 g of NaOH was weighed and dissolved in 180 mL of deionized water, and the metal salt solution and the precipitating agent were co-precipitated at room temperature, and the pH of the solution was kept at 9 during the precipitation process. After the precipitation is completed, treat at a constant temperature of 60°C for 5 hours, filter the obtained precipitate, wash with deionized water until the filtrate is neutral, dry at 110°C for 12 hours, grind it into powder, and roast it in a muffle furnace at 400°C After 3 hours, it was extruded under a pressure of 25 kN, crushed and sieved to obtain 20-40 mesh catalyst particles. That is, Fe-Al-Ce catalyst.

Embodiment 2

[0018] Embodiment 2: According to molar ratio n (Fe): n (Al): n (Bi)=10: 2: 1, take by weighing 50.6g Fe (NO 3 ) 3 9H 2 O, 9.4gAl(NO 3 ) 3 9H 2 O and 6.1g Bi(NO 3 ) 3 ·5H 2 O, dissolved in 600 mL deionized water. At the same time, 25g KOH was weighed and dissolved in 230mL deionized water, and the metal salt solution and the precipitating agent were co-precipitated at room temperature, and the pH value of the solution was kept at 9 during the precipitation process. The following process was the same as in Example 1; finally obtained Fe-Al-Bi catalyst.

Embodiment 3

[0019] Embodiment 3: According to molar ratio n (Fe): n (Al): n (Zr)=1: 1: 1, weigh 50.6g Fe (NO 3 ) 3 9H 2 O, 47.0gAl(NO 3 ) 3 9H 2 O and 53.8g Zr(NO 3 ) 4 ·5H 2 O, dissolved in 1350 mL deionized water. At the same time, weigh 36g Na 2 CO 3 Dissolve in 330mL deionized water, and co-precipitate the metal salt solution and the precipitating agent at room temperature, and keep the pH value of the solution at 9 during the precipitation process. The following process is the same as in Example 1; the Fe-Al-Zr catalyst is finally obtained .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com