Calcium magnesium injectable bone cement and preparation method and application thereof

A bone cement, calcium and magnesium technology, applied in medical science, prosthesis, etc., can solve the problems of reducing the injectability of calcium phosphate bone cement, dispersing or washing away the slurry, prolonging the curing time, etc., and achieving strong collapse resistance , fast curing speed, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

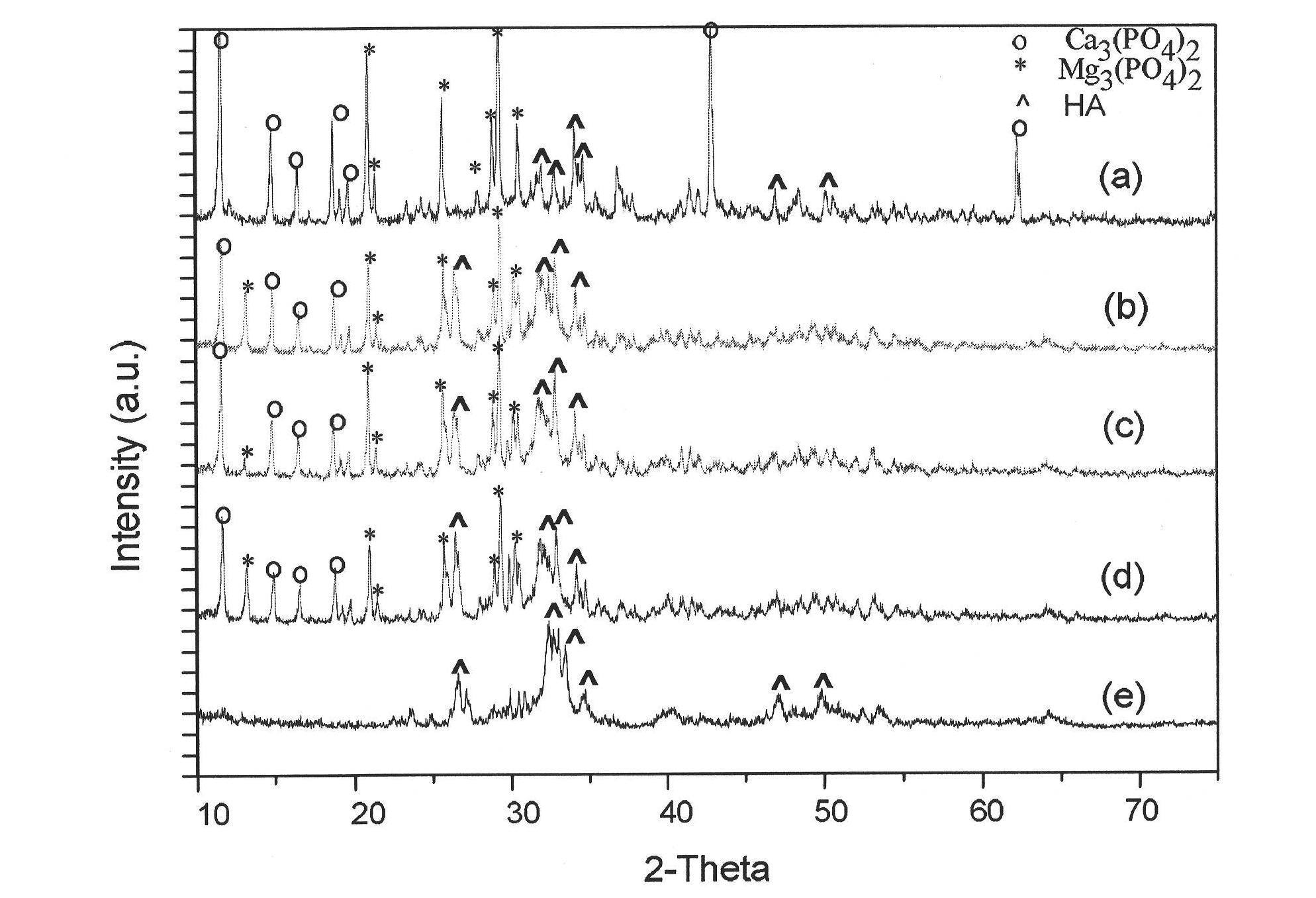

[0036] Weigh 10 g of composite calcium phosphate salt powder (composition is calcium hydrogen phosphate, tetracalcium phosphate and hydroxyapatite) with a particle size less than 10 μm as solid phase powder;

[0037] Weigh 0.48g of white dextrin and 0.48g of disodium hydrogen phosphate, pour them into a beaker equipped with 6g of deionized water, stir fully so that white dextrin and disodium hydrogen phosphate are fully dissolved in deionized water, and obtain a solidified solution;

[0038] Pour the solidified liquid into the solid phase powder, disperse evenly in the vessel, and mix evenly with a special mixing knife to obtain the aqueous phase injectable calcium phosphate bone cement.

[0039] Examples 2-12 Repeat the experimental steps of Example 1, the difference lies in the experimental conditions, as shown in Table 1.

[0040] The experimental condition of table 1 embodiment 2~12

[0041]

[0042] Table 2 shows the performance test results of the aqueous phase injec...

Embodiment 13

[0048] Weigh 0.5g of composite calcium phosphate salt powder (composition is calcium hydrogen phosphate, octacalcium phosphate and hydroxyapatite) with a particle size of less than 10 μm, and 9.5g of magnesium phosphate powder, and dry mix to form a solid phase powder; weigh white dextrin 1.2g, 1.04g of disodium hydrogen phosphate, poured into a beaker containing 6g of deionized water, fully stirred to fully dissolve white dextrin and disodium hydrogen phosphate into the deionized water to obtain a solidified solution;

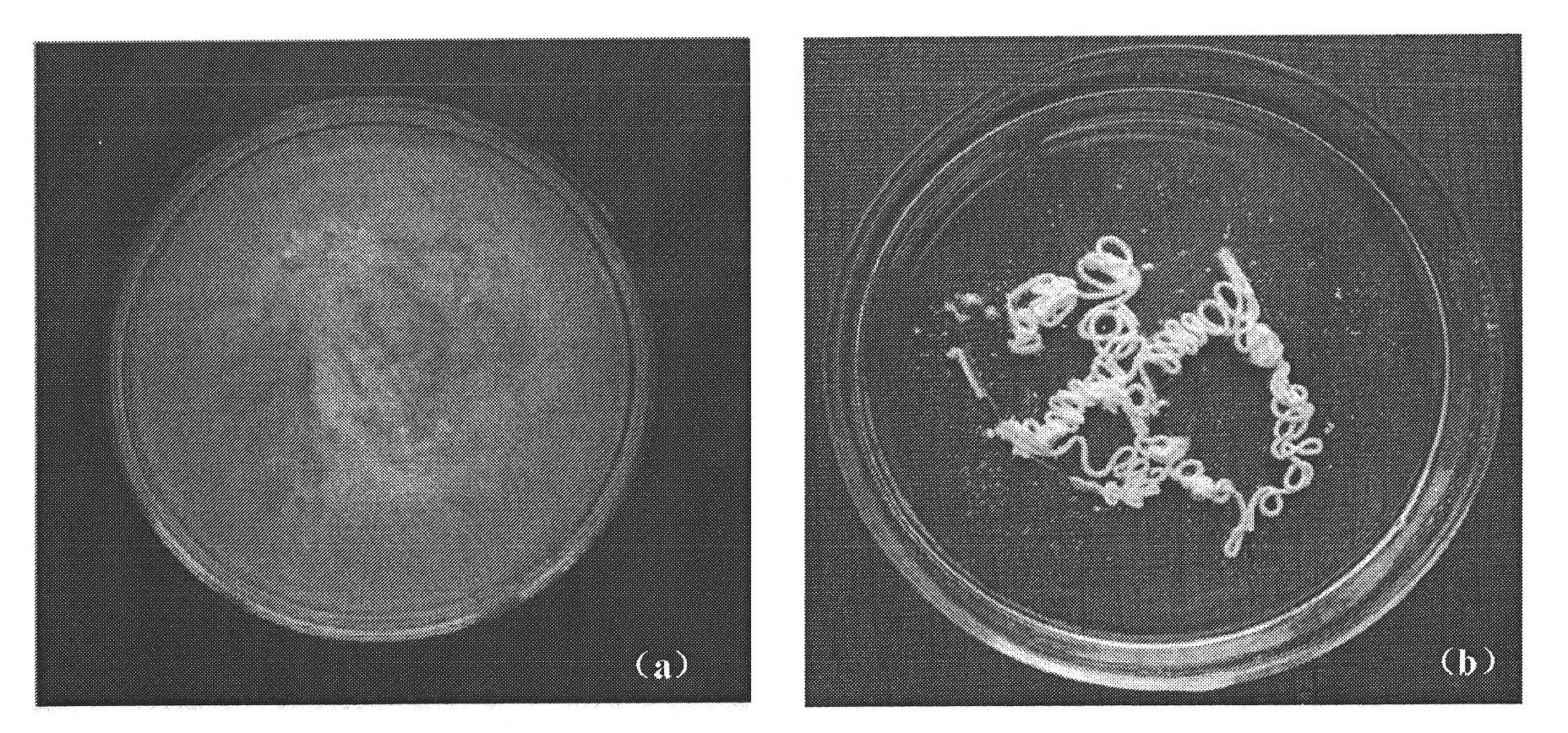

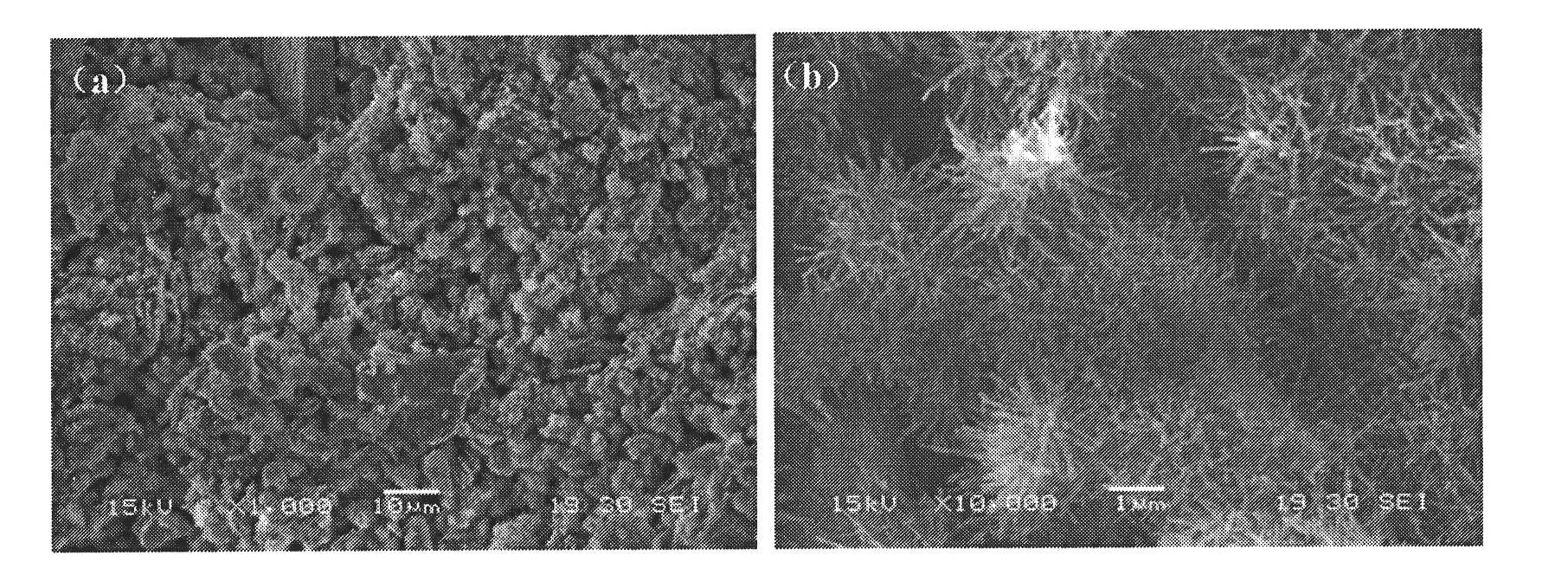

[0049] Pour the solidification solution prepared above into the solid phase powder, disperse it evenly in the vessel, and mix it evenly with a special mixing knife to obtain a water-phase injectable calcium-magnesium bone cement (fa-ICMB) with high-efficiency collapse resistance and rapid solidification.

[0050] Examples 14-24 repeated the experimental steps of Example 13, the difference lies in the experimental conditions, as shown in Table 3, and the perform...

Embodiment 25

[0057] Weigh 5 g of composite calcium phosphate salt powder (composition is calcium hydrogen phosphate, octacalcium phosphate and calcium pyrophosphate) with a particle size less than 10 μm, 5 g of magnesium phosphate powder, and dry mix to form a solid phase powder;

[0058] Weigh 1.2 g of white dextrin and 1.04 g of disodium hydrogen phosphate, pour them into a beaker containing 6 g of deionized water, and stir fully so that white dextrin and disodium hydrogen phosphate are fully dissolved in deionized water to obtain a solidified solution;

[0059] Pour the solidified liquid prepared above into the solid phase powder, disperse evenly in the container, and mix evenly with a special mixing knife to obtain the water phase injectable calcium-magnesium bone cement fa-ICMB with high-efficiency anti-collapse and fast curing.

[0060] Examples 26-37 repeated the experimental steps of Example 25, the difference lies in the experimental conditions, as shown in Table 5, and the perform...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com